French automotive brand and subsidiary of the PSA Group, DS Automobiles has announced its latest car model features 3D printed titanium parts. The DS 3 Dark Side edition uses innovative technologies such as 3D printing and ‘3D Skin’ technology to provide a premium feel to the car.

The 3D printed metal features in the interior of the car, while the 3D skin provides a unique feel, literally, to the car’s exterior.

Titanium finishing

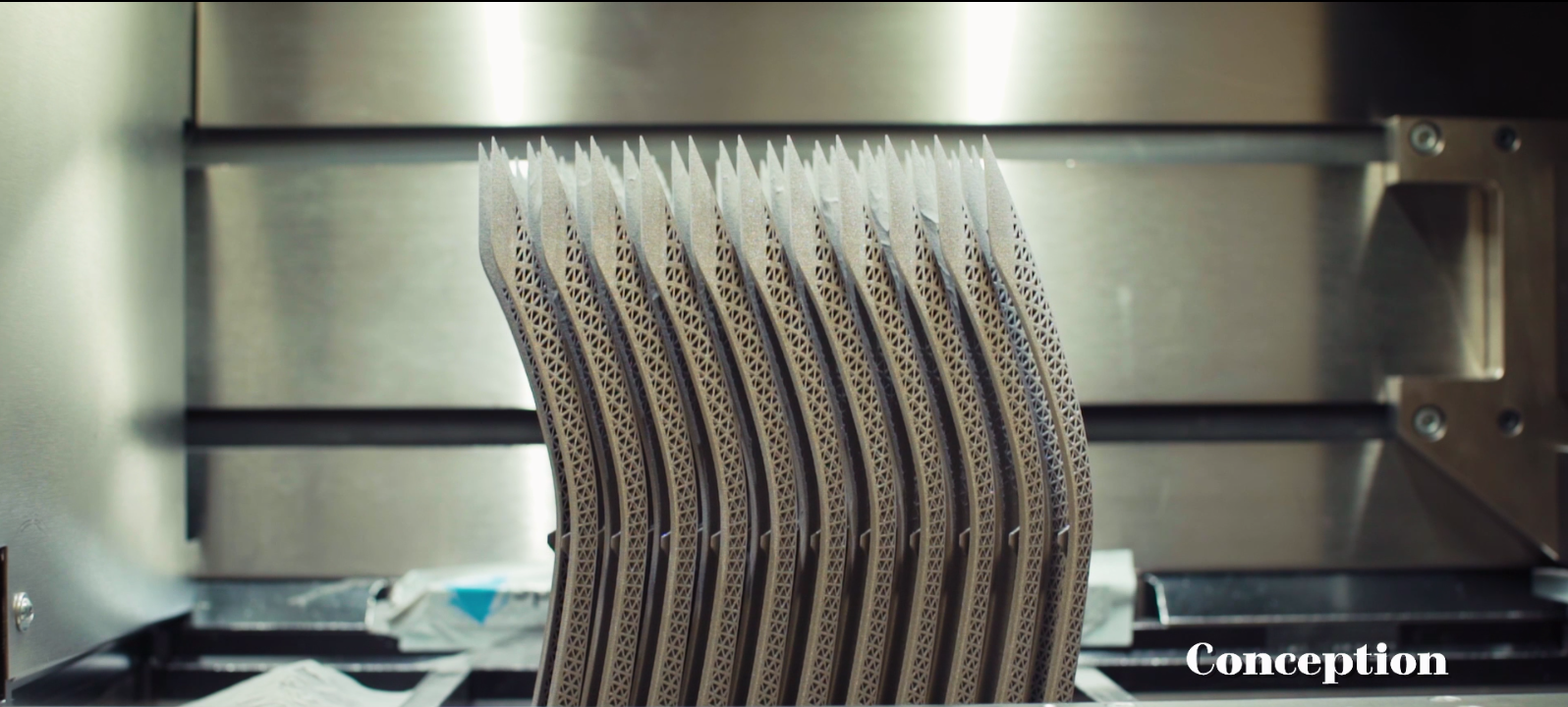

The DS Automobiles brand was first introduced as a brand of Citroen, however as of 2014 PSA Group markets DS Automobiles as a standalone premium brand. The automotive brand turned to 3D printing to create a luxurious feel in the interior of the car. To produce the complex titanium shapes which follow the curvature of the door handle, DS Automobiles used a laser powder bed fusion process.

Fusing the titanium powders in a 65 hour process, the company explains this was then combined with manual finishing to create a “high-tech design and craftsman finish.” The DS 3 Dark Side’s ignition key also features a 3D printed titanium metal part as a continuation of the premium metal aesthetic. The metal parts were designed by DS stylists using parametric design software which focuses on data and algorithms rather than the use of shapes. The technique has similarly been explored by fashion designer Mingjing Lin.

3D Skin technology

In addition to this, the company used another innovative technology which they refer to as “3D Skin”. DS Automobiles explains the process involves applying a granular spray coating to a film which has been cut-out with geometric designs. The technique has been employed by DS before but only in concept cars. DS Automobiles explains this is “the world-first application on a production vehicle.”

As part of the PSA Group, DS Automobiles works in partnership with 3D printing car company Divergent 3D. However, Divergent 3D’s use of 3D printing has focused on providing a more efficient and sustainable production process, rather than the creation of premium finishes. Divergent also has an agreement with German metal 3D printer manufacturers SLM Solutions.

Elsewhere, the use of 3D printing by the automotive industry to create complex functional parts and even to produce spare parts. German Automaker Volkswagen has recently launched a spare part initiative, while mechanics have also made use of the technology to reproduce antique car parts.

For all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows The DS 3 Dark Side edition. All images, including featured, via DS Automobiles.