PSA Group, the giants behind Peugeot and Citroën have signed a Strategic Partnership Letter of Intent with Divergent 3D – but what exactly is their intent?

Remember the 3D printed supercar from November 2015?

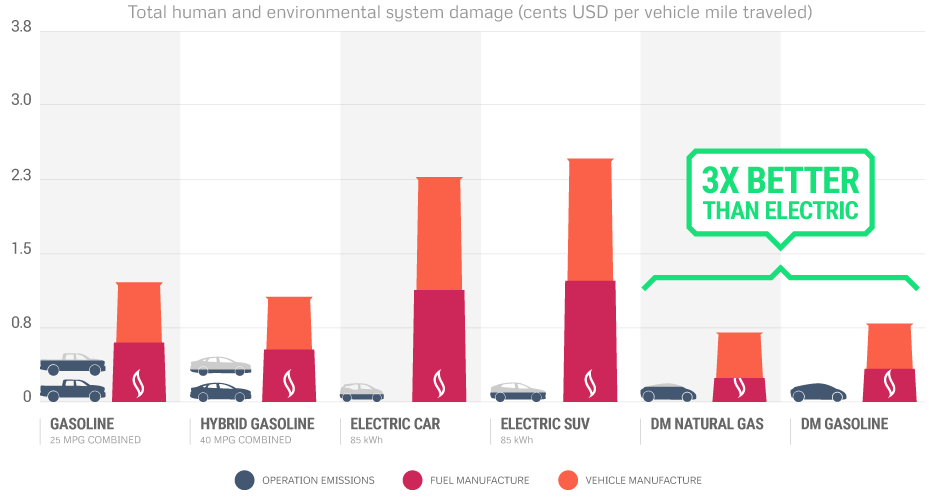

The aptly titled Blade, is a Divergent 3D project, and went on to win the North American Technology Innovation Award this year for its cutting edge status: boasting speeds faster than a Ferrari; one third of the weight than your average sports car; and, just as crucially, a dramatically lower environmental impact.

Manufacturing Emissions of Divergent Microfactories and Competitors

With a future demanding cars that are sustainable, efficient and conscientious, it is simply that the race is on to manufacture machines to meet this demand.

And, though the spare parts market is going to remain a cornerstone for the automotive industry for years – who hasn’t dropped their exhaust on the M1? – this particular partnership is instead looking to:

‘transform the design and manufacture of overall vehicle structures’ – PSA Groupe

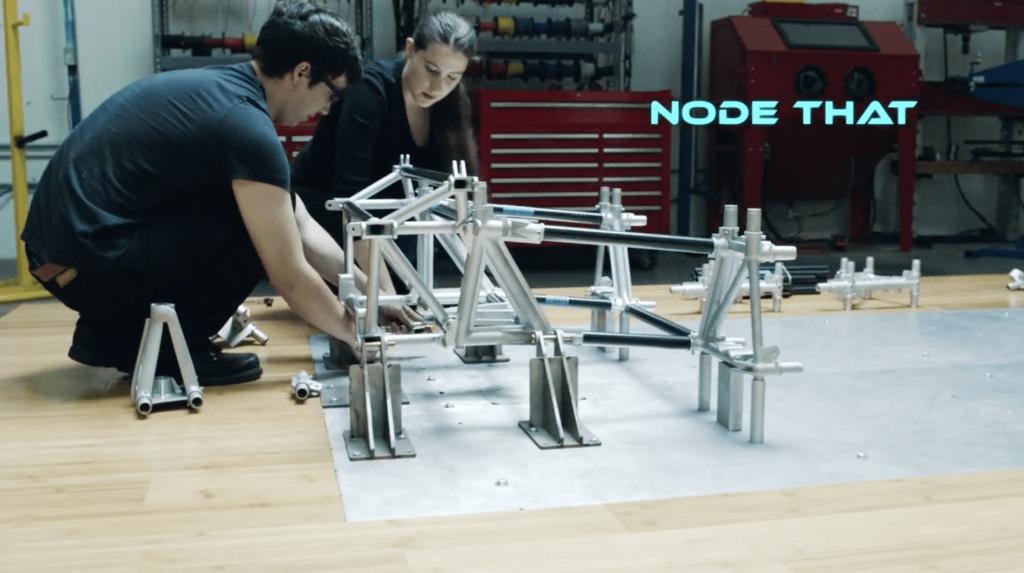

Part of Divergent’s success is in their trademark Node™ technology, which takes a modular approach to building cars. Since their inception, the company have been aiming to release this technology for startups to use, with an overall objective to democratize the car industry.

Here at 3DPI we wanted to know how such ideals work in collaboration with a decidedly more ‘corporate’ direction, and also what to expect from this ambitious project.

Read on for our interview with Divergent 3D CEO Kevin Czinger, talking more about cutting the weight of cars in half, non-exclusive partnerships with PSA and Altran, and the vision of a Divergent Manufacturing Platform™.

How long have you been exploring 3D printing technologies for car manufacturing?

We began research on using 3D printing to enable building modular chassis structures (to replace metal tooling and stamping for automobile manufacturing) in 2012 […]

We believe that 3D metal printing is an exponential technology that (when combined with other new technologies) will experience dramatic increases in print speed and quality over the next 3-5 years. Starting early in this space has allowed us to file what we consider to be the industry foundational patents for using 3D metal printing to build modular structures for a wide range of industries.

What are the most important things to consider about a partnership with PSA? What would you like to achieve together?

The primary objective of the partnership is to commercialize our proprietary software-hardware platform by building full vehicles with PSA using our (3D metal printing enabled) modular vehicle structure. This has the potential to dramatically change the economics and product cycle speed of car design and manufacturing. For example, we believe we can reduce the vehicle structure weight of a standard five passenger vehicle by over 50% and the number of parts by over 75%.

What can we expect from you in the next 6 – 12 months?

We are focused on building successful strategic partnerships with PSA and Altran, and continually expanding our IP portfolio. […] Both PSA and Altran partnerships are non-exclusive and we plan to be working with multiple OEMs over time. Our business model is focused on implementing and licensing our technology platform.

Are we going to be seeing any more supercars like the Blade?

The Blade is a technology demonstrator embodying the functional beauty that can be achieved through the new technology base Divergent is using. We continue to evolve the Blade chassis structure by building and testing versions of it. That is part of our core research & development.

Previously, we had heard that you might be making your Node™ technology available for start-ups to use, is that still true even with your corporate partnership?

Our long term vision is to have a technology platform – the Divergent Manufacturing Platform™ — that automates car design and radically reduces the cost and time required to manufacture vehicles. We need to commercialize and standardize the platform; the best and quickest way to do that is to work with major vehicle manufacturers like PSA.

[…]we are committed to democratizing and re-localizing manufacturing. Our strategy is to work with major OEMs to commercialize the Divergent Manufacturing Platform™. As the technology develops and cost comes down over the long term, we hope to be able to offer our technology platform to independent teams of vehicle manufacturers.

Without a doubt, the Divergent team remains committed to their goals, and the PSA Groupe is certainly making a smart move for the future.

I personally can’t wait to see what will be created by startups once the Node technology is available, and am waiting for the day that somebody prints a car in their own garage.