INITIAL, the Product Development, Additive Manufacturing, and Production Center of France’s Prodways Group, has partnered with L’Oréal to develop 3D printed resin injection molds enabling faster part production for cosmetic products.

The method, dubbed 3D Molding, is said to cost-effectively manufacture final material parts in a record time of two weeks. “This unique solution is aimed at designers in the development phase and complements our traditional machining and injection solutions,” said Yvon Gallet, Chairman of Initial.

“It is an innovative alternative that meets the needs of manufacturers, like L’Oréal, that could benefit from this technological advance to reduce their time to market.”

3D Molding for L’Oréal

In 2015, INITIAL became a part of Prodways a subsidiary of Groupe Gorgé, an independent group specializing in advanced technologies, such as additive manufacturing. With its Tooling and Injection-site located in Chavanod, France, INITIAL utilizes the Prodways Materials range of resins and 3D printing technologies to create bespoke products with short lead times.

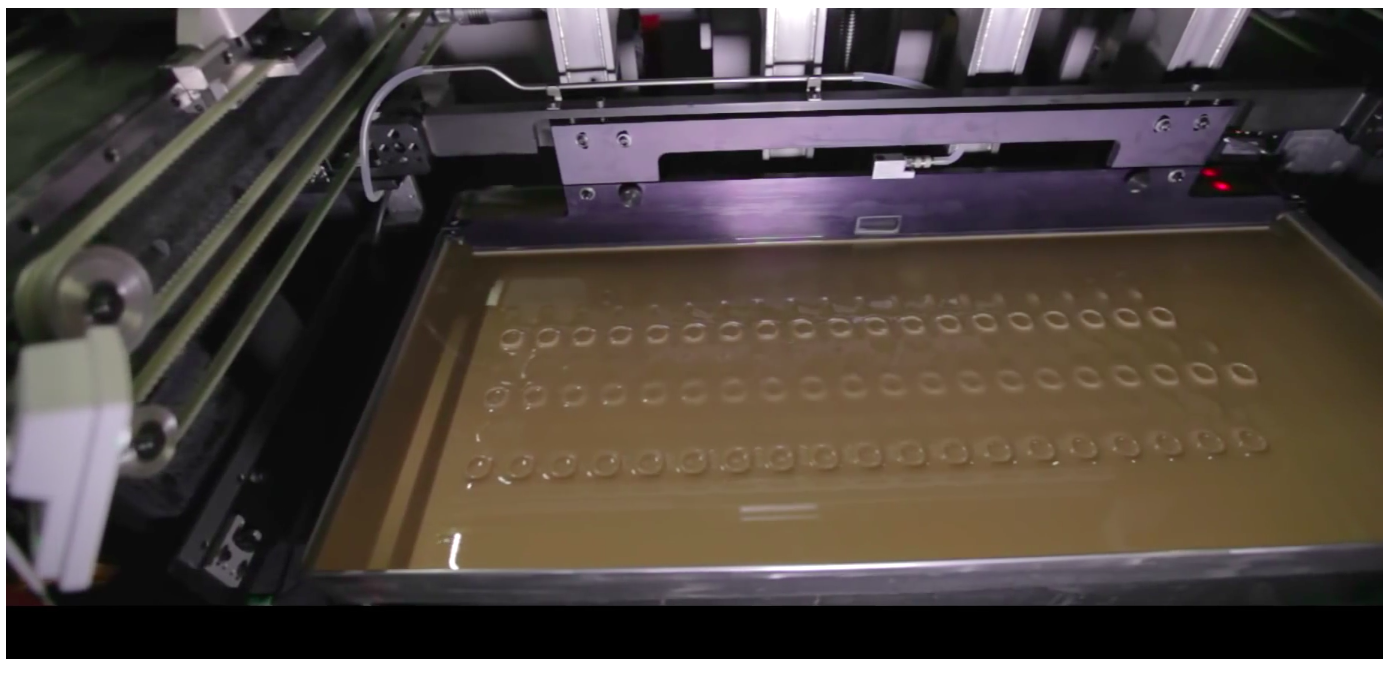

Recognizing the importance of time-to-market, L’Oréal sought out INITIAL to accelerate the development of 14 resin test molds as well as conduct 20 injection-molding test runs for several hundred molded parts. Using Prodways’ trademarked MovingLight Digital Light Processing (DLP) technology with PLASTCure Rigid 10500, INITIAL designed and 3D printed the required molds demonstrating “extreme accuracy and excellent resistance to injection-molding constraints.”

“With our 3D printing and injection expertise, we [can] produce the 3D Printing mold and the final material parts [which] are then directly injection-molded,” added Gallet.

With reduced production costs as a result of a shortened lead time, L’Oréal can increase its approval and iteration processes for new packaging of its beauty products. This allows the company to stay abreast of the fast marketing of new products within the cosmetic industry.

MOVINGLight 3D printing technology

MOVINGLight utilizes photopolymerization to produce high-resolution parts at high speeds from plastic and ceramic materials. In L’Oréal’s case, where a liquid resin was used, Prodways would have used its ProMaker series of 3D printers suitable for injection mold making.

The 3D Molding method, as well as its application in the cosmetic sector, will be discussed next week at Luxe Pack Monaco, a premier show on creative packaging.

3D Printing Industry Editor-in-chief Michael Petch will be moderating a panel discussion at Luxe Pack entitled “Additive manufacturing in the service of the luxury brands – New solutions and experiences.”

Stay updated with the latest 3D printing news by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows a 3D printed mold from INITIAL. Photo via Prodways.