Automated post-processing system manufacturer PostProcess has officially launched the 2021 edition of its annual Additive Manufacturing Post-Printing Industry Trends Survey.

After last year’s report showed that post-processing has become a vital efficiency-driver for manufacturers during the pandemic, this year’s is once again appealing for the 3D printing industry’s feedback on related methods, challenges and applications. Once collated, this year’s data is also set to be split by market and technology, giving readers a clear idea of users’ experiences and future plans.

Those familiar with operating post-processing machines are invited to take part between now and September 29, 2021, with participants having the chance to win one of five sets of Beats Studio Buds. After the survey’s results have been collected and analyzed, PostProcess intends to release a comprehensive, market-segmented report in early October.

Post-printing’s growing influence

Although 3D printing is often marketed as a high-tech disruptive technology, many users still rely on manual methods of removing excess material and finishing the surfaces of parts. In doing so, these manufacturers are not only damaging their own productivity, but often relying on the use of harsh chemicals that come with inherent safety and sustainability risks.

To get around this, a number of post-processing units are now available, which automate such laborious processes, by removing supports and delivering end-use quality finishing en-masse. Commercial adopters therefore stand to benefit from higher throughputs, while their technicians are freed-up to work on value-oriented tasks, saving firms from having to spend on labor at a time of COVID-19 cuts.

However, despite the labor constraints and supply chain disruption caused by the pandemic, PostProcess maintains that it has also allowed “3D printing’s adaptability and on-demand nature to shine.” In order to continue this trend, the firm is now calling for all post-printing users to come forward, share their experiences and contribute to a resource that could inform the development of future machines.

Breaking down a turbulent 2020

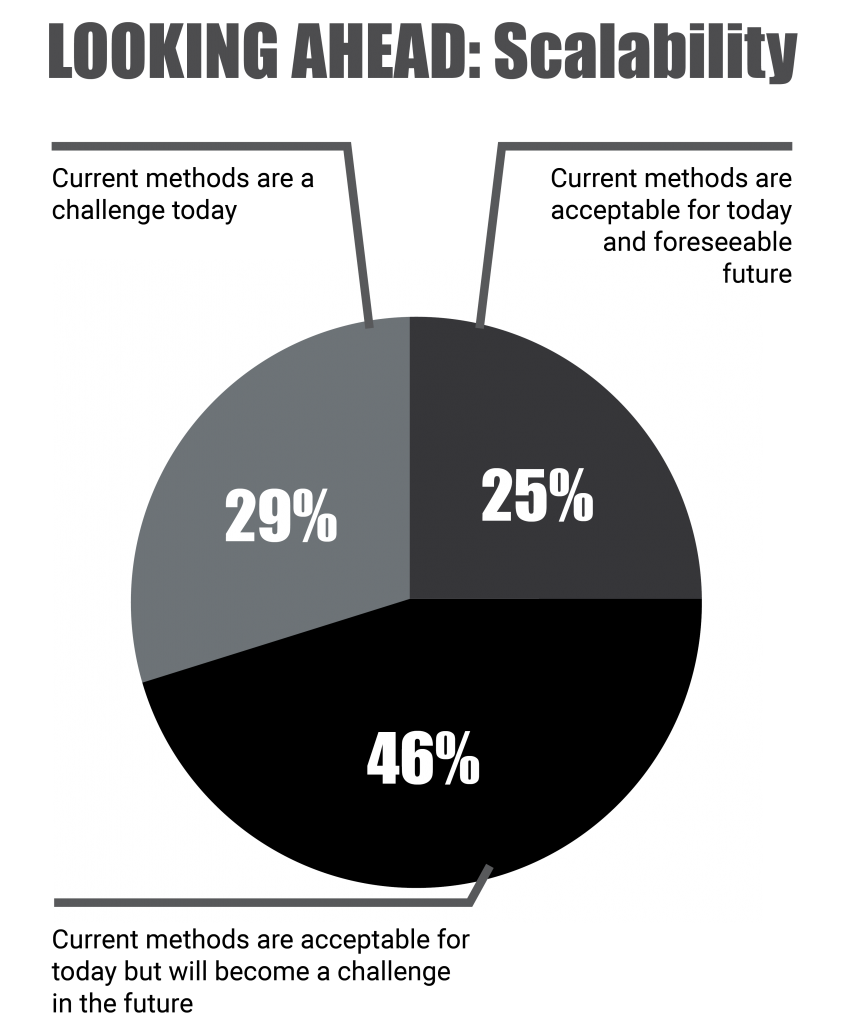

Last year’s survey results were truly one-of-a-kind, given the extremely difficult conditions faced by many manufacturers. This was reflected in the answers of its contributors, with the use of skilled labor rising up the report’s ‘Top Post-Printing Challenges’ table. What’s more, 75% of respondents also reported using three or more technologies, suggesting that simplified processes are now critical to scalability.

When broken down by technology, some 71% of contributors said they leverage FDM, while 50% reported using Vat Photopolymerization, and 41% admitted deploying PBF. Interestingly though, SLA, DLP and CLIP users were actually most concerned about the safety of their technologies, while those post-processing metal, were more likely to see current workflows as a “challenge to reaching their goals.”

Similarly, results showed that 67% of those operating in defense also find post-processing to be a limiting factor in attaining production targets, while 50% of automotive users felt the same way. Given that these two sectors have been hard-hit by the pandemic, this outcome suggests that new solutions need to be developed which meet this demand, and enable the technology to flourish in key printing markets.

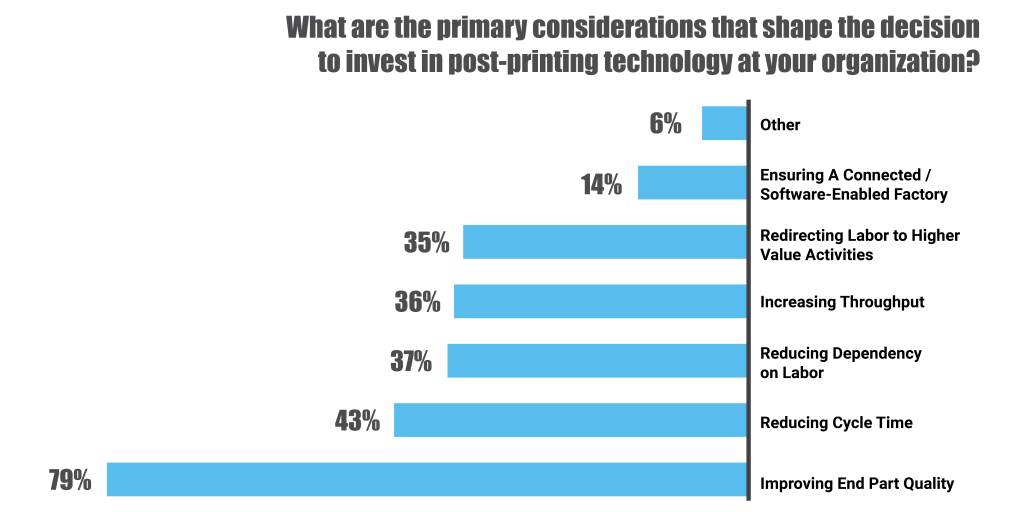

The survey also found that a whopping 79% of respondents consider ‘improving end part quality’ to be their main priority when buying a post-processing unit, with ‘reduced cycling times’ a distant second (43%), and just under half of all respondents (46%) agreed that current systems are “acceptable for today but will become a challenge” in future.

With its 2021 survey, PostProcess is now calling on those involved with the post-processing of 3D printed parts, to contribute their expertise once again. Now that the pandemic seems to be receding, these responses are likely to provide a vital insight into the post-COVID world, and whether the priorities of post-printing users have changed accordingly.

How to participate

According to PostProcess, the 3D printing sector is “in a unique position of rapid growth,” and its survey could help maintain this, by collating data on the current landscape. As an added bonus, contributors will also be entered into a prize draw for one of five sets of Beats Studio Buds, thus the survey is a worthwhile endeavour for all involved.

The full 2020 report can be accessed here.

Take part in the 2021 survey here.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows an engineer using a PostProcess machine. Photo via PostProcess.