PostProcess Technologies has just launched the 2020 iteration of its annual Additive Manufacturing Post-Printing Industry Trends Survey.

After a successful debut in 2019, the post-printing (aka post-processing) specialist is again looking to share insights into the 3D printing industry’s most common post-printing methods, most frequently faced challenges, and growth plans. This year’s survey is packed with improvements and new questions, all designed to help shape and refine the post-printing strategies of those interested.

Readers familiar with post-printing are encouraged to take part between now and August 7th, as five lucky participants will be selected to win an Apple Watch. Once the results are in, the data will be tabulated and summarized along with key highlights and insights in a comprehensive report set to be published in early September.

The importance of post-printing

The often overlooked post-printing stage is just as critical as the design and printing stages of the additive workflow. According to PostProcess, more and more companies are considering it, however, as production volumes grow and competitiveness relies ever more on part quality.

The term itself is quite a broad one – some might accept it as traditional finishing machinery adapted and applied to additive manufacturing. Alternatively, others may exclusively see it as the highly manual hand finishing process commonly found in the hobbyist community. The truth is: automated additive-specific post-printing systems have always lagged behind the 3D printer market. The result is this comparatively underdeveloped marketspace that has great potential – not just for post-printing adoption, but for additive adoption as a whole.

Locked behind a simple Google search, however, there exists a trove of dedicated support-removal, resin-removal, and surface finishing systems specifically for additively manufactured parts. These machines do away with the previously tedious process, instead enabling mass support removal and end-use worthy surface finishing at high throughput. Although many of them can be very refined, they are still playing catch-up with the ever-growing mountain of hardware and materials being pumped out by printer manufacturers and feedstock companies – so there’s some ground to cover.

The post-printing trends of 2019

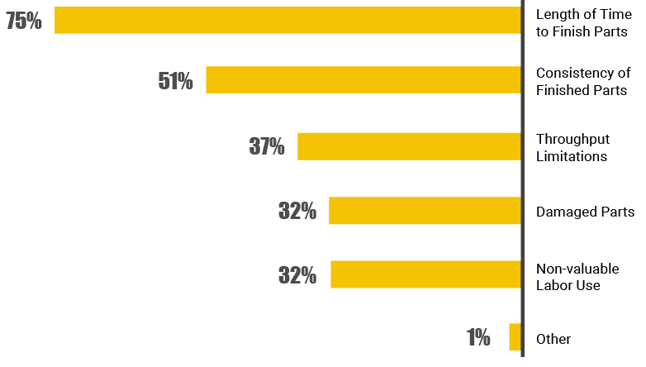

Last year’s results were nothing short of illuminating. When asked about the challenges faced in the post-printing stage, a whopping 75% of users cited ‘length of time’ as the most common hurdle. In PostProcess’ eyes, this is especially concerning as most of the surveyed users intend on scaling up production in the next 3 – 5 years. With increased volumes, companies involved with rapid prototyping rely almost entirely on efficiency and timely workflows, as delivery time is one of the key factors a customer will consider when choosing a supplier.

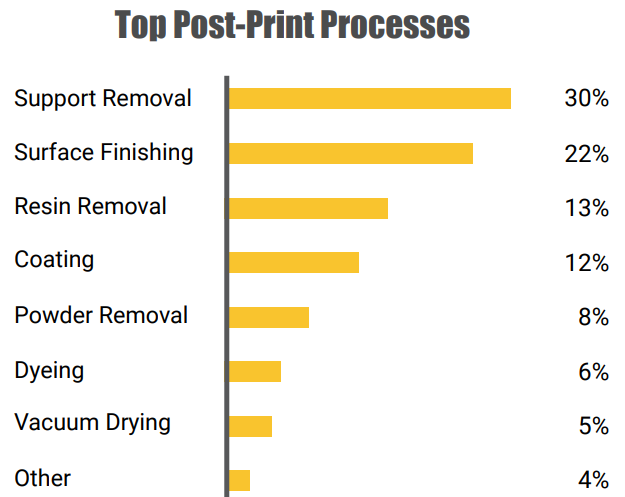

Looking at the data for the most commonly used post-printing techniques, support removal and surface finishing lead the charge with 30% and 22% of the respondents respectively. Those that undergo the support removal step usually spend more than half of their time on it, indicating that it is a major time-vampire.

With the third most common process, resin removal, a surface finishing step is also required 80% of the time. The results shine a light on the relationships between these processes – their dependencies and complements. The level of insight provided by the survey leads us to strongly encourage professionals concerned with this portion of the additive workflow to participate.

The full 2019 report can be accessed here.

Take part in the 2020 survey here.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

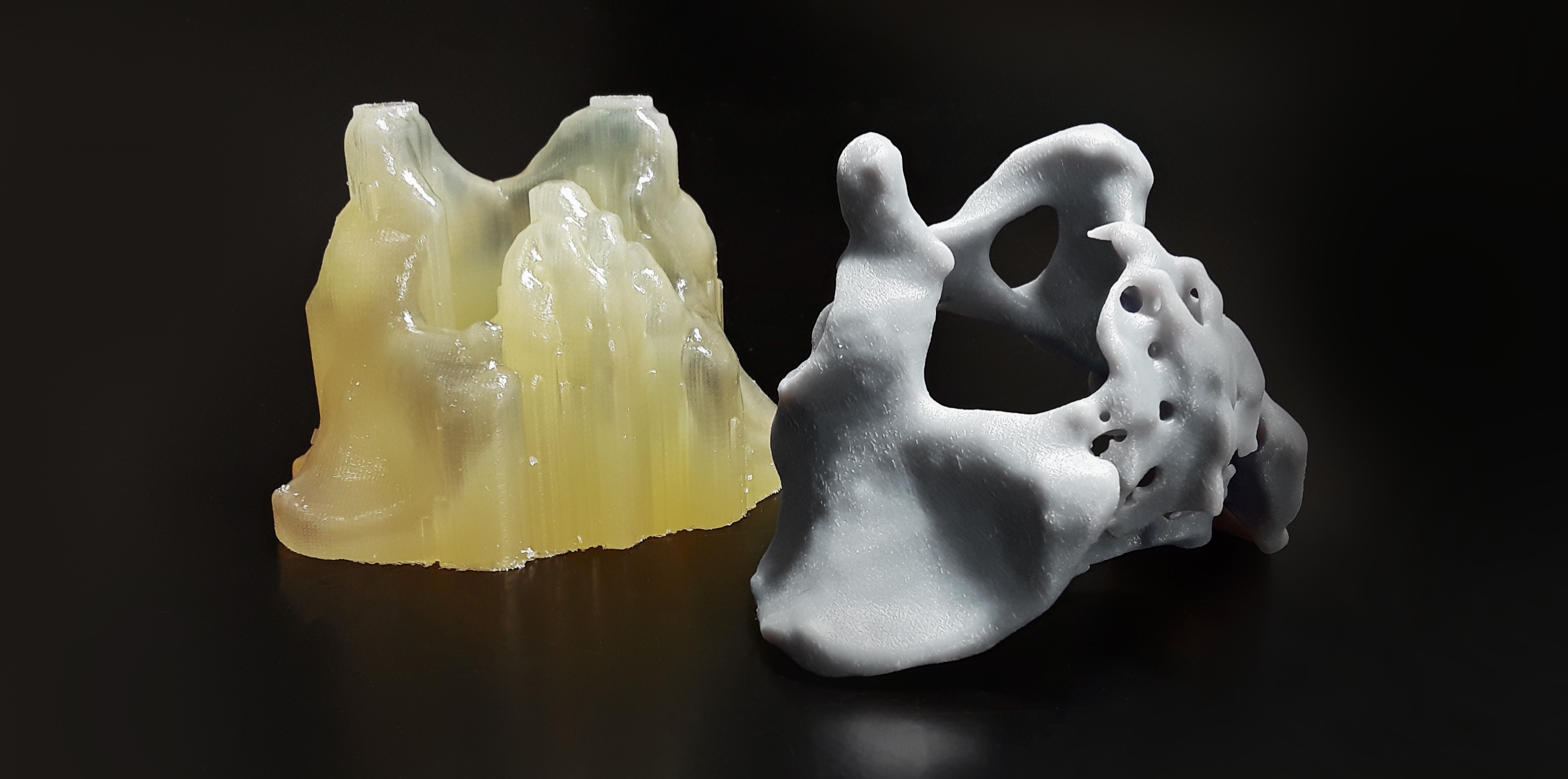

Featured image shows a 3D printed pelvis model post-processed using PostProcess’ automated systems. Photo via PostProcess Technologies.