By: Robert Bowerman

Robert Bowerman is an Autodesk Technology Consultant within the field of Additive Manufacturing, working with development teams, industrial partners, and hardware vendors to democratise Metal Additive and Hybrid Manufacturing through the creation of easy to use, accessible, and integrated software workflows.

What is DED and why should you be using it? Part One

Whilst you’ll likely be familiar with Fused Filament Fabrication (FFF) and perhaps Power Bed Fusion, either plastic or metal, there’s a chance you’ll be less familiar with Directed Energy Deposition (DED). With a growing user base, an increase in accessible hardware, and a myriad of applications, you should care about this technology and what it can offer the manufacturing supply chain.

What is DED?

DED is a metal Additive Manufacturing process, whereby molten metal is selectively deposited, in layers, to build fully dense components. You may have heard of WAAM (Wire Arc Additive Manufacturing), LMD (Laser Metal Deposition), LENS (Laser Engineered Net Shape), DMD (Directed Metal Deposition), or some other acronym, but don’t be confused, these are often just proprietary names that equipment manufacturers use to differentiate their offering. Whilst there are many names, the technology only really has a few variations.

In general, a DED system requires three main components; a manipulator, to control where the metal is deposited, a feed of material, and an energy source to melt that material. The manipulator is usually in the form of a CNC gantry or a robot. The material will either be in wire or powder form and the energy source is either a laser or an electric arc (electron beams can also be used but are less common due to their cost).

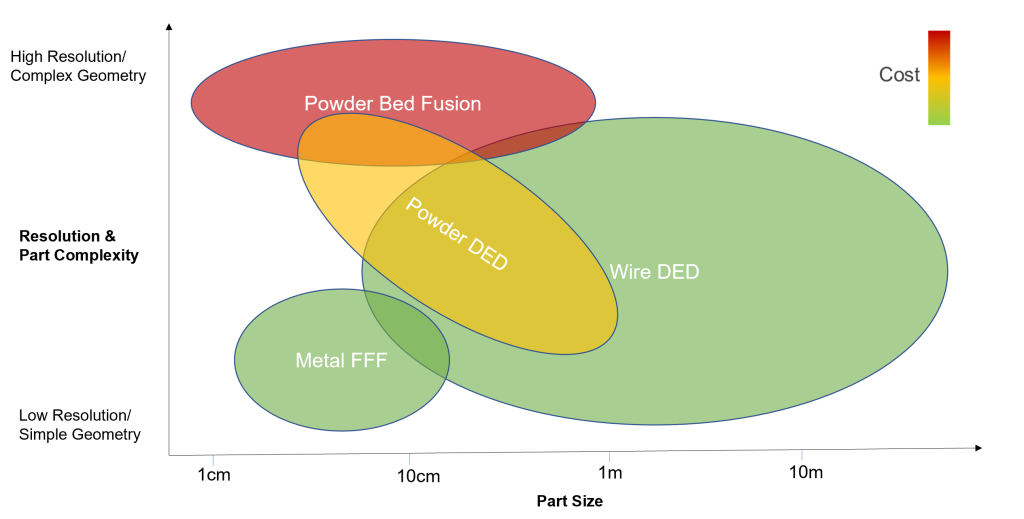

Compared to other metal AM processes, DED’s higher deposition rates have lent the process to producing larger scale (often 1m +) components, the trade-off to this level of productivity is part resolution. However, with the advent of new DED hardware, we are starting to see a wider breadth in what is possible with the technology and in some cases rivalling the detail that can be achieved by a powder bed system.

The higher deposition rates of the process can result in poorer geometrical accuracy, feature resolution, and surface texture, therefore components produced by DED are often machined after the deposition to achieve a final finish. This need for machining and the relative ease of integrating the technology into existing milling platforms has led to the rise of hybrid machines (that is, a machine with both additive and subtractive capabilities). Often these machines will comprise of more than 3axis, thus opening a plethora of opportunities to deposit material beyond the conventional constraints of planar layers.

What are the benefits of Multi-axis printing?

Many low-cost plastic 3D printers are of a 3axis configuration. Proving to be affordable, reliable and with plenty of software slicing options available, 3axis printers have flourished. However, this success has also limited 3D printing capability; support structures are required to enable the printing of overhanging surfaces, parts can only be built onto flat surfaces and not pre-existing geometry, curved upwards facing surfaces suffer from the stepping effect. With the advent of new 3D printing systems and the increasing popularity of integrating deposition heads onto CNC milling machines and Robotic arms a range of new printing possibilities are being made available and DED technology has been making use of multi-axis toolpaths for some time.

Why DED?

Much of the general AM benefits also hold true for DED, but why are companies really interested in the technology today and what are the future opportunities it offers?

At Autodesk, we’ve worked with a multitude of end users across industry over the past decade. Like much of metal additive, initially, most applications belonged to aerospace and over subsequent years we’ve seen that expand to marine, oil and gas, moulding/tooling, defence, and heavy industry. Whilst the applications, alloys, and part sizes vary, across these industries, most business cases could be summarized into two key areas, maintaining, or increasing competitive advantage and improving sustainability credentials, arguably, in that order of priority.

Today, DED can enable competitive advantage by reducing part development cycles and production lead times, improving time to market, and reducing the need to store spare parts. In the future, the technology could be used to produce high-performing, value-added components, taking advantage of the greater design and material freedoms the technology can offer. For example, optimising a component for structural or thermal load or producing a part in a custom alloy or combination of several alloys.

Also today, DED enables improved sustainability credentials by improving material efficiency in the manufacturing process, i.e. the part that is deposited (known as a near net shape, pre-form, or deposition model) requires significantly less material removal to achieve a finished part when compared to machining a part from billet of material. However, a cautious viewpoint should be taken here, and the entire lifecycle of component needs to be considered to truly understand the environmental credentials of any process or component. In the future, DED and AM facilities offer a decentralised production model, that is, parts don’t need to be produced in a single factory and shipped to their end use location, but can be produced on-site, when required. Leading to a reduction in transportation-induced carbon.

What are the current use cases?

Today’s use cases of the technology align well with the benefits that the process offers. They are broadly broken down into three categories, supplementing existing supply chains, reducing spare parts, or re-manufacturing and disrupting industries.

Supplementing supply chains: aerospace has long been the leading advocate of this use case (and possibly DED in general). Aerospace supply chains consume a significant quantity of high-value alloys and therefore strive to reduce the quantity of material wasted in the manufacturing process. Coupled with this, exotic alloys can often be difficult to machine (that is, slow and require a lot of expensive tooling), by reducing the amount of material you must cut, you save a lot of money. To achieve these gains, particularly for structural aircraft elements, companies will produce a near net shape component via a forging process and remove minimal material to reach the final part. The issue here is the time it takes to receive those forgings, which can be months, and the level of inflexibility and further delays when, for instance, there is a design change. This is where DED steps in and can act as a supplement to the supply of forged components.

Re-manufacture and reducing spare parts: DED offers a fantastic solution for re-conditioning of worn parts, this could be a high-value aerospace component (turbine blades and blisks are commonly used as an example here) or a piece of mould tooling, e.g. for an automotive application. If a component cannot be reconditioned and a replacement is required, it can, in some industries, lead to long downtimes of equipment whilst the replacement is sourced. In the Marine industry, they overcome this issue by keeping a store of spare parts. However, as you can imagine, this is a highly ineffective use of space. Here, DED offers the opportunity to reduce the physical storage and replacing it with a digital library of spare parts that could be produced by any system on demand, at the location it’s needed. Companies such as the Ramlab are actively exploring these opportunities with industrial partners.

Over recent years we have seen the rise of new organisations, appearing in long-standing industries, looking to disrupt the incumbents. Leveraging the technology benefits identified above, these fresh, fast-paced organisations are asking big questions and challenging the norms of industry. Pix Moving and Relativity Space are two of note. Pix Moving is utilising the toolless nature of the DED process to offer bespoke design as well as decentralising the manufacture of their autonomous vehicles. Relativity Space is aiming at disrupting the space industry by significantly reducing the time from concept to test to final part for rocketry components, using their multi meter WAAM system titled “Stargate”.

These are true pioneers of the technology and even if their success is short-lived, it is hoped that they will impart some impact on how we make products going forwards.

Whilst there have been significant technological advances and several good news stories to share around DED, ultimately the technology remains niche, and the challenges prohibiting wider adoption, large. There’s still much work to be done to progress the accessibility of hardware and software, improve process reliability and robustness, and upskill current and new engineers maximise the processes’ benefits. However, the good news is, there are some great advances being made right now to address these challenges.

Want to learn more about DED? Part 2 of our series on DED will be coming very soon!

Interested in Fusion 360? Download a free trial here

Featured image shows the WAAMpeller. Photo via Ramlab.