It turns out that lockpicking is not just for locksmiths, burglars or a skill only secret agents and cops on TV shows learn, but it is an actual hobby that has quite a few dedicated enthusiasts. There is even professional competitive lockpicking, would you believe, called Locksport. And before you roll your eyes and laugh at the silly things that people waste their time on, remember that you likely buy expensive robots that squirt molten plastic into the shape of Yoda heads for fun. Also, when there is a professional frisbee golf league throwing tournaments with $50,000 prize purses I think tut tutting silly hobbies seems like a bit of a waste.

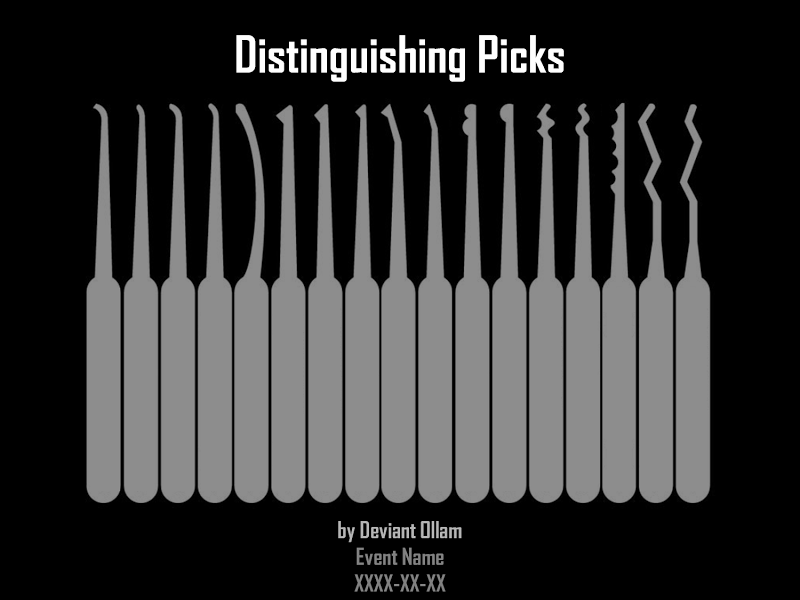

Lockpicking isn’t just about having some fancy metal picks to do all the work, there is a skill involved and the need for extensive knowledge about how various types of locks work. Of course having the correct tools is still important. After a colleague of his tried making some temporary lock picks from zip ties for fun, a maker calling him/herself Machinist on the 23b Shop blog had the idea to 3D print her/himself a set. But creating working lockpicks isn’t as easy as going to Shapeways and downloading a model.

“The shape is easy to make, yet difficult to reproduce exactly,” Machinist explained in the blog post. “I encounter the same challenge when making metal picks. They’re easy enough to form quickly by hand, but they’re impossible to duplicate precisely. When the performance of the pick is so dependent on the exact shape of the pick, consistency is king.”

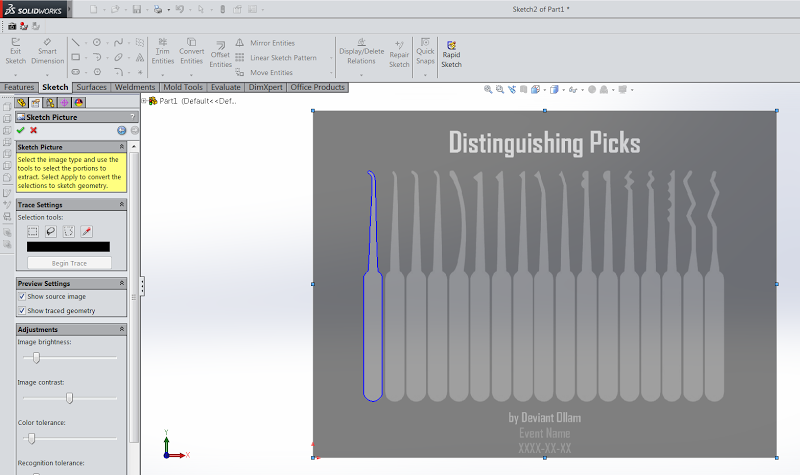

Discovering the Autotrace tool in 3D design software Solidworks helped Machinist complete the quest. Autotrace allows a user to turn a 2D image into a CAD file that can be manipulated into a 3D image. In the case of creating lockpicks the only thing that s/he needed to do was extrude the model, clean up some rough edges and modify some geometry. The only difficulty came in creating the correct pick thickness.

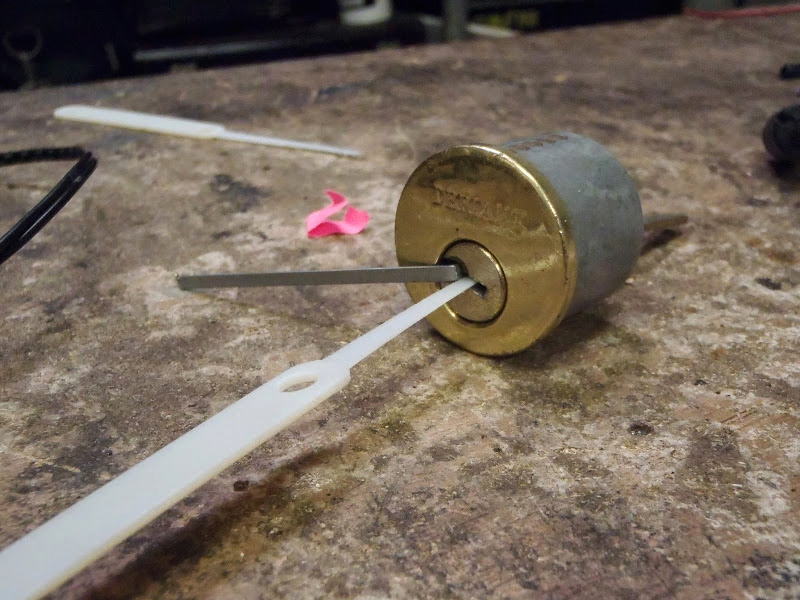

The 23b Shop’s Stratasys Dimension 768 SST was unable to produce the correct size required because layer thickness is 0.010 while the correct lockpick thickness is .023. But luckily Machinist works for a company that has a Stratasys Objet 30 Pro, with access to. With the Objet Machinist was able to create a set of lockpicks because it is capable of producing models with a .001 layer thickness and 600 DPI resolution.

Machinist got to work on a Defiant lock and within only a few moments he was able to open it using his new 3D printed picks, but did say that while many of the picks worked as required, not all of them were scaled appropriately so they didn’t fit the lock as needed. But since they created them from digital files, scaling new versions is rather simple.

As you’d expect from any maker, Machinist is not done tinkering with the 3D printed lock pick set. The plan is to create new tweaked versions that s/he hopes will be more reliable and is even planning on creating some new designs from scratch and creating a link of them that can be injection molded.

If you’re curious, you can read more about Locksporting and the extremely rigorous ethical guidelines that are strictly enforced to prevent people from getting the wrong idea about their hobby here.