Researchers from The University of The Punjab, Mirpur University of Science & Technology, Bahaudin Zakaria University and Lahore College for Women University, have optimized the controllable dosage of antibiotics tablets using 3D printing.

Utilizing Fused Deposition Modelling (FDM) technology, the research team 3D printed tablets of equal size, but with varying percentages of infill and drug concentration. The team identified a direct link between the release rate of the antibiotic, and the tablet’s infill percentage, which enabled them to control its dosage by adjusting its printing parameters. Future applications of the technique could lead to the development of personalized medicine for antibiotic patients, and enhanced clinical outcomes for the severely ill.

3D printing’s antibiotic applications

Antibiotics are an important weapon for clinicians in the battle against pathogens and managing critical illnesses, with the potential to enhance patient care or even reduce mortality rates. Having an optimized approach to dosage is essential to reaping these benefits, and suppressing the development of resistant pathogens.

Ideally, the dosage of these drugs would be customized to the patient, and focused on the specific disease to avoid the risks of over or under-dosage. While this isn’t currently commercially plausible, pharmaceutical companies are increasingly turning towards alternative manufacturing methods to develop customized-dosage capable tablets.

The advantage of using 3D printing to produce drugs is that it allows for different geometrical structures to be built in a layer-by-layer fashion, and when guided by a digital model, the release of the dosage can be controlled. A multitude of AM methods have already been tested by other researchers to 3D print tablets, but the Pakistani team opted for FDM due to its accuracy, adaptability and cost-effectiveness. Moreover, the simplified development processes and enhanced in-built quality of dosage forms by FDM, make it an attractive technique for the production of customized drug-delivery systems.

Using FDM 3D printing, the team sought to control the dosage of the widespread spectrum antibiotic called Ciprofloxacin hydrochloride (ciprofloxacin-HCl). The drug is effective against both complicated and uncomplicated urinary, severe lower-respiratory tract, gall-bladder and intra-abdominal infections amongst others. Nonetheless, in order to effectively fight these diseases, the appropriate dosage for each patient will depend on how advanced the illness is, and factors such as their age and weight.

In addition, only a small number of strength variants for the drug have been made commercially available, and bulk-purchasing in hospital settings hasn’t been feasible or economical. As a result, the research team began developing ciprofloxacin-HCl tablets with differing dosages, in order to optimize its efficacy against multiple infections, and make it customizable to each patient.

Producing the 3D printed tablets

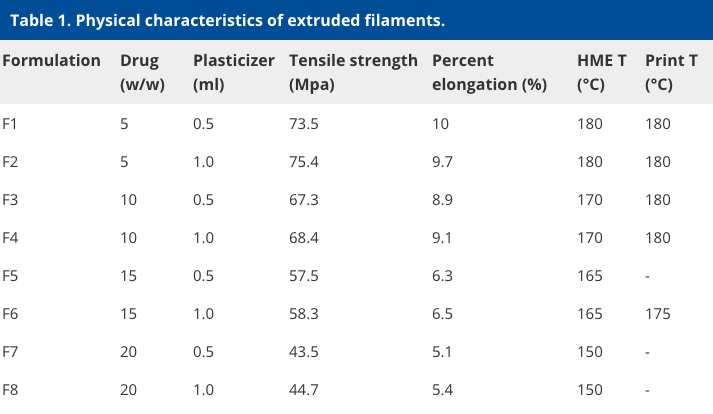

The tablets were created using a polyvinyl alcohol (PVA) biocompatible and water soluble polymer due to its comparatively-low melting point of between 190 and 210° C. Drug-loaded PVA filament was fabricated through a hot melt extrusion (HME) technique using a Makerbot 3D printer, to replicate ciprofloxacin-HCl tablets in specific strengths. The polymer melts were extruded through a circular die of 1.75 mm, and guided onto a conveyor belt for cooling and to ensure uniformity of diameter. Extruded filaments were then stored in air-tight containers, with a total of eight formulations containing strengths of between five and twenty percent (w/w) ciprofloxacin-HC, which were fabricated in 50g batches.

Mechanical testing of the extruded filaments was performed to check their printability with respect to drug loading and composition, and to compare the drugs to those that are commercially available. Results showed that enhancing the drug proportion to 15 percent or above, resulted in mechanically weaker filaments that could not be easily printed through the FDM process. Filaments with a drug proportion of 10 percent or less on the other hand, were stronger and could be successfully fabricated. This was due to the fact that the MakerBot 3D printer needed to be used with a filament diameter of 1.75 mm, in order to achieve the required level of 3D printing accuracy.

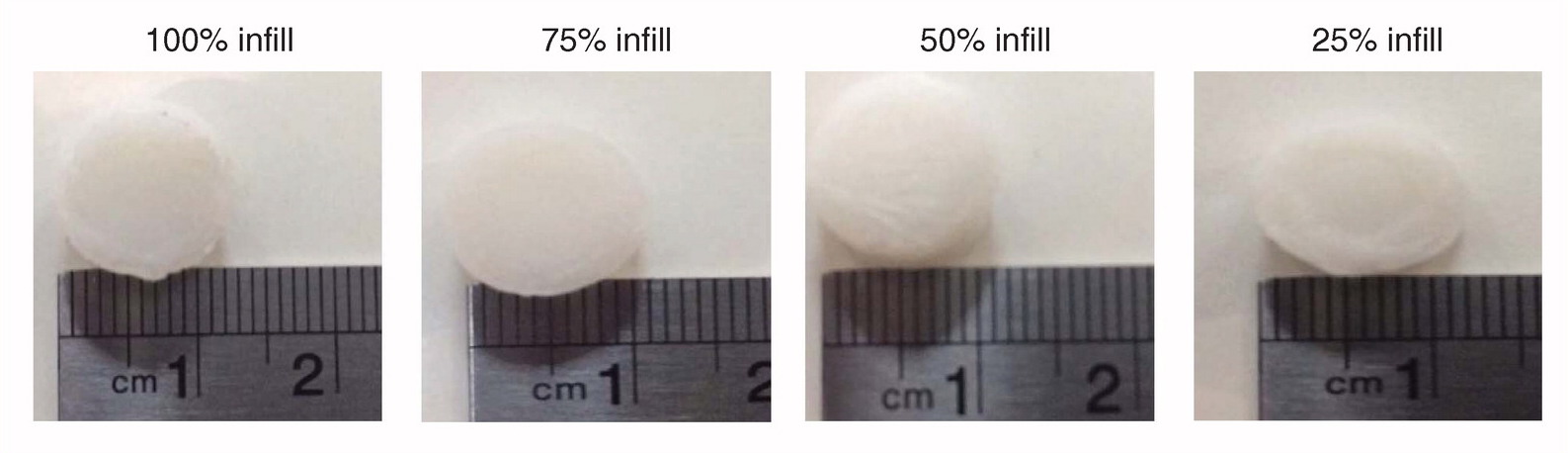

Critically, the team found that dissolution patterns could be altered by changing the printing parameters, and tablets were successfully printed with 25, 50, 75 and 100 percent infill percentages. Moreover, while the increase in infill percentage predictably increased the tablet’s weight, the size of the tablets stayed almost the same. The drugs also demonstrated high reproducibility and resistance to damage on handling, showing a mechanical strength of 340 to 400N for the 25 percent tablets, and close to 495N for the higher percentage tablets.

While the 25 percent infill tablets were observed to give complete drug release within four hours, the 50, 75 and 100 percent tablets showed a slower release after an initial burst. This indicated that the rate of drug release could be slowed down with a higher infill percentage. In the case of low (25 percent) polymer infill tablets, dissolution was also found to be fast due to the presence of channels in the tablet structure by virtue of its design. As more of its surface area was exposed to the dissolution medium, the drug release was mainly dissolution dependent.

The research team concluded that FDM 3D printing could effectively be used to fabricate ciprofloxacin-HCl, with customized oral dosage. Release patterns were tailored by adjusting the printing parameters, and a rapid drug release was obtained by lowering the infill percentage of the tablets. This advance in 3D printing, could not only lead to tablets that have patient-specific dosage, but also improve survival rates among the critically ill.

“This work is potentially significant for optimized antibiotic dosing, which in turn leads to enhanced clinical outcome,” said the research team. “Further advancement and sophistication in the field will allow this promising move to become an authentic method of producing personalized medicines.”

Tablets used in additive applications

3D printing has been utilized to produce tablets to fight a range of different illnesses in the last few years. A team of researchers from University College London (UCL) for instance, used 3D printing to create opioid tablets (tramadol) with alcohol-resistant and abuse-deterrent properties. The researchers created the tablets to combat the growing global health crisis of opioid abuse caused by the over-prescription of high-strength painkillers.

Global pharmaceutical company Merck, worked with AMCM, an EOS Group company that builds custom additive manufacturing machines, to develop and produce 3D printed tablets using powder bed fusion technology. The partnership was seen as “a step towards the digitization of the industry.”

British 3D printed pharmaceuticals company FabRx, used 3D printing to develop personalized medicine for children with the rare metabolic disorder, maple syrup urine disease (MSUD). FabRx’s 3D printed chewable tablets called ‘Printlets’, offered a rapid and automated alternative for the preparation of tailored therapeutic dosages.

The researchers’ findings are detailed in their paper titled “Fabrication of modified-release custom-designed ciprofloxacin tablets via fused deposition modeling 3D printing” published by the Future Medicine journal. The report was co-authored by Nasir Abbas, Nadia Qamar, Amjad Hussain, Sumera Latif, Muhammad Sohail Arshad, Qazi Amir Ijaz, Faisal Mahmood and Nadeem Irfan Bukhari.

You can now nominate for the 2020 3D Printing Industry Awards. Cast your vote to help decide this year’s winners.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a 3D printed tablet produced by the Pakistani research team. Image via the Future Medicine journal.