Picatinny Arsenal has revealed a litany of potential electronic applications for additive material and 3D printing. Most of the projects listed would have a direct impact in the military field, and anything cutting down the weight and price of battle equipment would be welcome throughout the ranks. With specific additives, Picatinny looks to provide radio frequency to helmets, clothing even weaponry for signals and communication. Of course, electronic equipment is not limited to ground forces, and Picatinny Arsenal foresees 3D printing in Unarmed Arial Vehicles or UAV’s. While radio frequency and electronic components in arsenals and vehicles is not new, it is what 3D printing allows that has Picatinny Arsenal giddy.

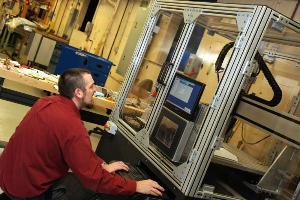

Picatinny’s research delves into the process and applications for electronic 3D printing. With a heating source, materials like gypsum, metal powders, plastic filaments and others can be melded and added layer by layer as those familiar with 3D printing are aware. The printers can produce ink that can conduct electric current (like silver) and print onto film surfaces creating conductors, semi-conductors and resisters. With similar methods, research suggests we can print electronics such as munitions antennas, fuse elements, and batteries.

“Instead of having to machine out the groves and put the sensor and the wires in the model, I can just use our printers to print electronics onto the model so they are already embedded,” Zunino said.

“With printed electronics versus conventional you’re not chemically etching away all the material, you’re printing them the way you want them. It’s more environmentally friendly, it’s more cost effective and it’s more time efficient.”

For applications in radio, for instance, a radio antenna made of silver nanoparticles printed onto a flexible polyimide substrate could be embedded into a Soldier’s helmet, replacing the antenna that currently attaches to the headgear. Zunino continues to mention the potential for electronic equipment picking out chemical changes warning soldiers of nearby anthrax or other hazardous chemical compounds.

Other potentials include UAV wing production and in-field applications. Picatinny can see every soldier equipped with a 3D scanner sending needs to the closest printer. Scientists express hope that even mine production appears feasible with recent developments, an example of “cube” manufacturing for weaponry. In the future it will be easier and faster than ever to create machines of war and soldiers with embedded radio frequency, oh brave new world. Yet it may be with such force, all fronts, from east to west may quiet from recent roars.

Source: North Jersey