High-powered blue laser specialist NUBURU has added seven new patents to its intellectual property (IP) portfolio in visible laser technologies with applications across 3D printing and materials processing.

The company has been awarded four new patents from the US Patent Office and three foreign patents – Russian, Japanese, and Korean – which will be included in NUBURU’s foundational patent ‘3D Printing Devices and Methods’ (PCT/US14/35928).

“NUBURU’s IP portfolio is broad and deep,” said Dr. Guy Gilliland, CEO of NUBURU. “Industry analysts and organizations have recognized the strength of our technology and its IP portfolio, including StartUp Insight, who identified NUBURU as one of the Top 5 Additive Manufacturing Start Ups Impacting The Automotive Industry.”

NUBURU’s blue laser technology

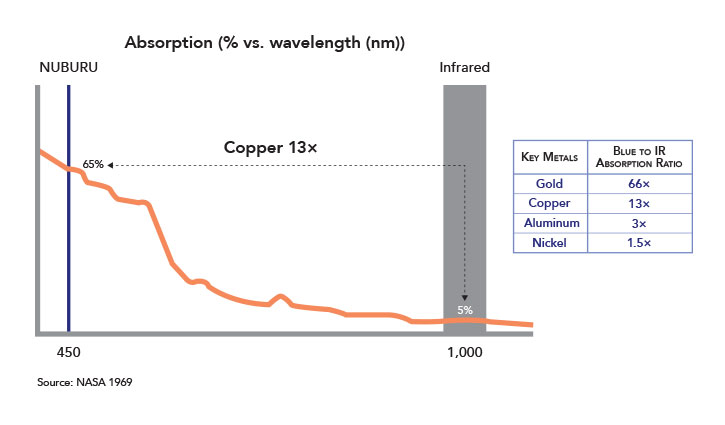

Founded in 2015, NUBURU develops blue lasers for metal processing operations across industries such as e-mobility and automotive, where materials such as copper, stainless steel, and aluminum are of increasing importance. These darker metals have a higher absorption rate in the blue spectrum, and the company claims that its lasers could “transform” the speed and quality of welding, machining, and 3D printing certain alloys.

NUBURU’s lasers are designed to optimize the performance of laser cladding and Laser Metal Deposition (LMD) machines within 3D printing, by enabling copper to be clad to other copper surfaces. Reportedly, the technology can increase print speeds tenfold within LMD in comparison to regular systems.

At the tail end of last year, the firm raised $20 million in Series B funding in order to develop its AI welding system and expand its presence in the energy, e-mobility, and 3D printing markets. To date, NUBURU has raised a total of $50 million in funding.

New patents across 3D printing and materials processing

NUBURU’s latest patents cover several of its material processing lasers, alongside the technology required to build these single mode visible lasers. The US Patent Office awarded four patents, ranging from its Monolithic Visible Wavelength Fibre Laser, Multi-Clad Optical Fibre, and Very Dense Wavelength Beam Combined Laser System, to the applications, methods, and systems for materials processing with its Visible Raman Laser.

NUBURU also received patents from Japan, Russia, and Korea for its technology, all of which join the firm’s foundational patent. The patent, ‘3D Printing Devices and Methods’, has been awarded in 16 countries so far, with several applications and continuations currently pending around the world. NUBURU has also received multiple notices of allowances for the technology and the application of blue lasers within 3D printing and material processing.

“These patents firmly establish that NUBURU invented the blue laser technology for 3D printing and material processing,” said Dr. Mark Zediker, Founder and Chairman of NUBURU. “The company portfolio widely covers blue laser technology, multimode and single mode as well as broad applications within 3D printing and material processing.

“22 patents have been awarded to date, with 90 applications currently in process for a number of claims in excess of 4,000.”

Deploying blue laser technologies for 3D printing

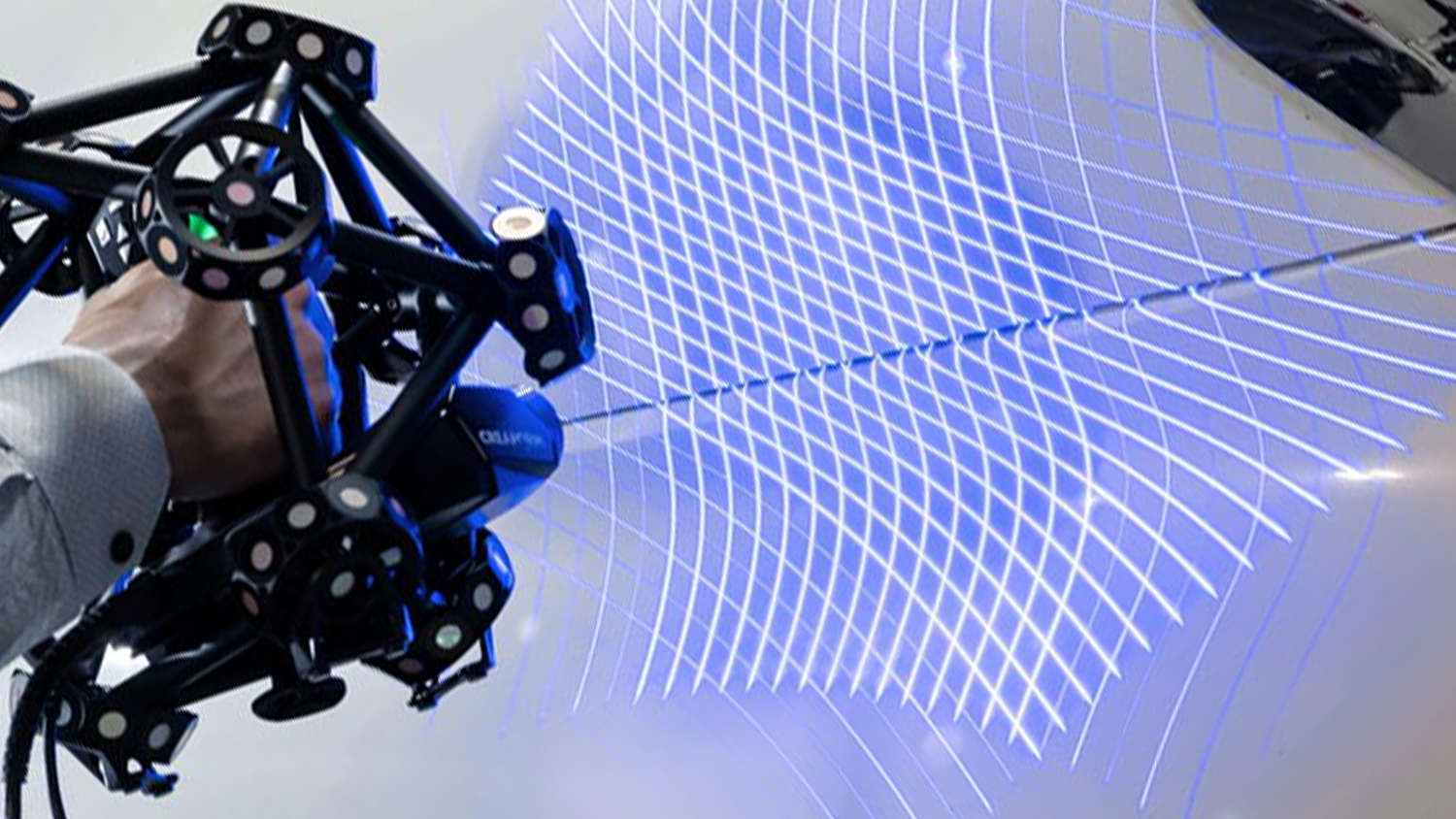

Blue lasers have been experimentally implemented within a small number of 3D printing systems, an example of which is the integration of NUBURU’s technology into 3D metal manufacturer Formalloy’s L-Series of LMD machines. Producing a spot size five times smaller than that of infra-red lasers, the blue lasers aimed to help Formalloy’s machines to “3D print, repair and clad metallic parts” with greater speed and accuracy than other methods.

Elsewhere, global engineering firm Renishaw has implemented blue lasers within its NC4+ Blue non-contact tool measurement solution, seeing improved diffraction effects and optimized laser beam geometry in comparison to infra-red sources.

Blue lasers have also been utilized in the area of 3D scanning, such as in measurement system manufacturer Creaform’s latest 3D scanner, the MetraSCAN BLACK. The scanner features 15 blue laser crosses which contribute to an extremely fast 3D scanning process. Meanwhile, leading 3D printer and scanner manufacturer Shining 3D launched its EinScan HX handheld 3D scanner equipped with a blue laser to enable superior performance when scanning reflecting and black surfaces.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows dough baked by a blue laser. Photo credit Jonathan Blutinger Columbia Engineering