The National Institute of Standards and Technology (NIST) has awarded nearly $4 million in grants to advance the competitiveness of U.S. metal 3D printing firms.

Using the funding, four research teams will develop standardized measurement techniques that could make adopting additive processes much easier to do. By removing barriers to entry such as part accuracy, speed and quality issues, NIST aims to help more U.S. companies create complex goods in higher volumes.

“NIST and the entire Department of Commerce are committed to providing American organizations with the resources to thrive,” said U.S. Secretary of Commerce Wilbur Ross. “I congratulate these grant awardees, whose contributions to metal-based AM will certainly help America play a bigger role in the industry.”

Standardizing metal 3D printing

NIST was set up in 1901 to remove any challenges to the industrial competitiveness of the United States, and it’s now a division of the U.S. Department of Commerce. To this end, the agency continues to support the standardization of technologies, by advancing the science of measurement, and funding areas of promising research.

Over the last two years, the agency has increasingly sought to help American firms optimize the 3D printing process, and unlock its commercial potential. To begin this process, NIST invited industry experts to a Colorado workshop in 2019, at which it attempted to establish a roadmap for the future of SLA additive manufacturing.

The agency is also home to one of the oldest science labs in the United States, and it often develops enhanced 3D printing methods of its own. For instance, last year NIST scientists found that X-ray curing could be more efficient than using UV lasers, while another team was able to map polymer hardening rates during production.

With its latest round of grants, NIST is now expanding its work from a core focus on polymerization, into the field of alloy-based 3D printing. By working closely with all four funding recipients over the next two years, the agency aims to standardize both the set-up and computational requirements of metal systems.

NIST’s additive funding recipients

The University of Texas at El Paso is one of three academic institutions to receive a grant, and it intends to use the funding to standardize data collection within LPBF 3D printing. During the project, industrial partners will continually attempt to replicate an object, with the inputs being used to better understand the process’ mechanics.

Purdue University, meanwhile, aims to reduce the number of tests required to qualify printed parts, by developing a standardized approach to predicting their properties. Using computational models and material microstructure analysis, the team believe that it’s possible to streamline the current qualification process.

Northeastern University has also gained just under $1 million in funding, with which it’s set to create a suite of new sensor technologies that could optimize cold spray 3D printed parts. The devices are being designed to characterize the properties of powder feedstock, and identify set parameters that provide better process control.

Finally, the Georgia Tech Research Corporation has received a grant to fund its research into improving the predictability of PBF additive manufacturing. The team aims to establish a comprehensive method for verifying and validating parts, with an initial focus on qualifying titanium for healthcare and aerospace applications.

Although NIST hasn’t specified its plans for future funding, it has alluded to a second phase of grants that are scheduled to be awarded at some point during H1 2021. According to NIST Director Walter G. Copan, the current crop of R&D programs could make American companies more competitive in the global marketplace.

“By addressing important measurement challenges, these projects will improve U.S. manufacturers’ ability to use metals-based AM to make high-quality, innovative and complex products,” said Copan. “We look forward to working with these organizations to further leverage NIST’s experience and expertise in this key area.”

The growing regulation of metal AM

Developing a set of accepted 3D printing standards is viewed by many within the industry as a valuable way of making the technology accessible within potentially lucrative markets.

Global standards developer ASTM International has also issued significant funding to several projects that aim to address the need for standardization within 3D printing. The group awarded $300,000 to nine different programs in September 2019, that are each working to expedite the qualification process.

Elsewhere, U.S. national accelerator America Makes and the American National Standards Institute (ANSI) have taken a broader approach, releasing a portal for tracking standards activity online. The website compiles any gaps within the current regulatory framework, enabling users to work towards addressing them with R&D.

Similarly, the global Metal Powder Industries Federation (MPIF) has published a set of 3D printing powder characterization standards online for public access. The document is a compilation of nine existing test methods, that’s designed to allow manufacturers to better commercialize the technology.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

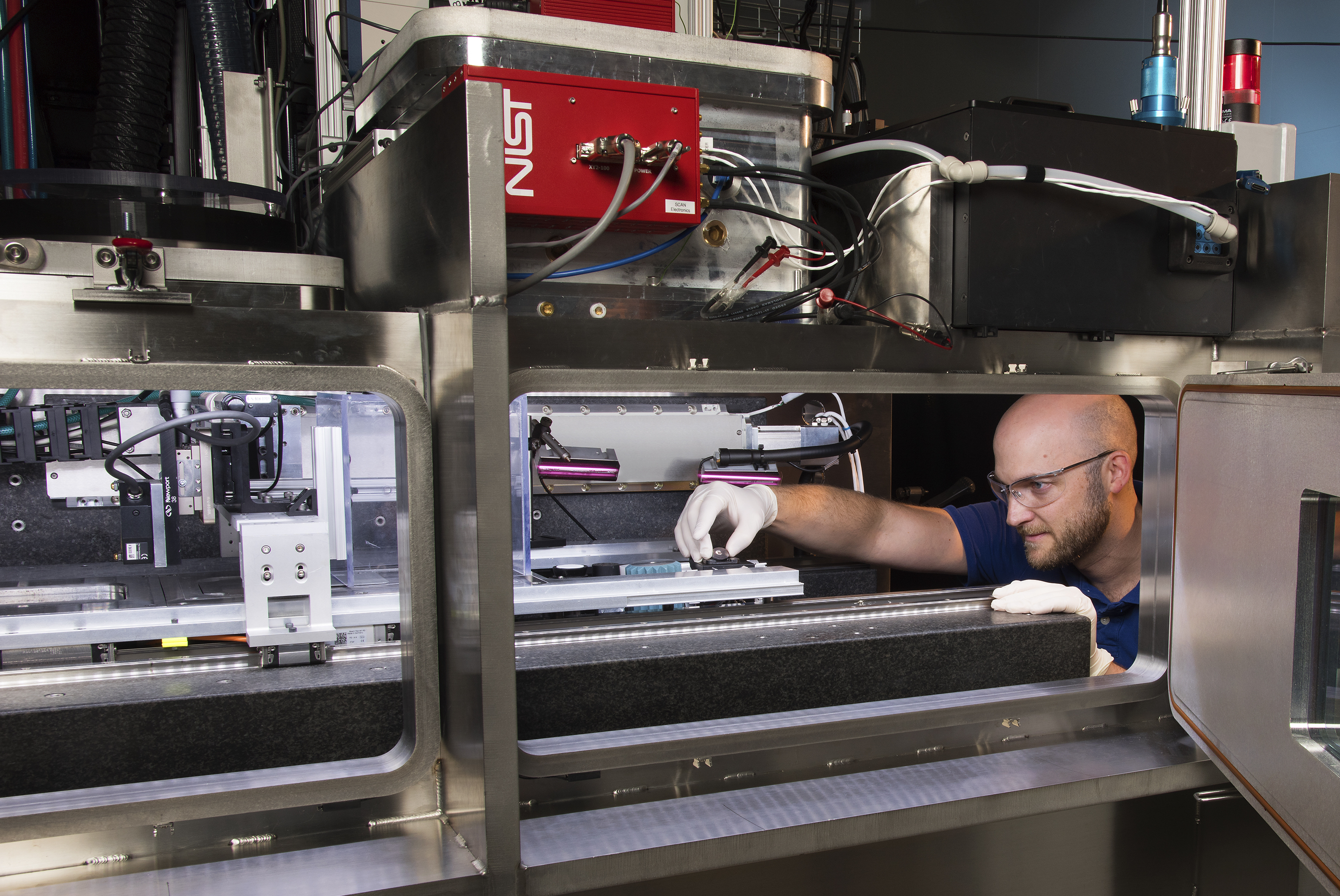

Featured image shows a test engineer configuring one of the NIST lab’s 3D printers ahead of testing. Photo via NIST, Earl Zubkoff.