Engineering software developer nTopology is currently working on a whole slew of new developments for its topology optimization platform.

Commercialized back in 2019, the firm’s software bridges simulation and generative design, enabling users to create complex parts optimized for additive manufacturing processes. As such, the platform embodies the principles of Design for Additive Manufacturing (DfAM), bypassing the geometric limitations of today’s conventional engineering design tools.

nTopology’s innovations are used to address some of the most difficult engineering challenges in industry, including lightweighting, thermal management, mass customization, architected materials, and manufacturing and tooling.

Following its recent third-generation latticing technology launch, the firm is now in the process of developing several upcoming design tools such as field-driven lattice optimization capabilities, custom graph unit cells, and more.

“We are excited to release the latest generation of our lattice technology, which will continue to fundamentally change how engineers approach design for additive manufacturing,” said Trevor Laughlin, VP Product at nTopology. “This new technology will enable industry-first advancements such as field-driven optimization, where the software automatically designs lattice structures for user-defined objectives and constraints. Ultimately, this will allow our customers to more effectively make use of the AM design space, resulting in innovative applications faster than ever before.”

A leader in engineering design

Founded in 2015, nTopology has proven itself to be one of the major players in the generative design space. The company’s advanced algorithms are trusted and leveraged by a wide variety of manufacturing firms, including Ford, Lockheed Martin, and Honeywell.

To complement its part design capabilities, nTopology offers multiple avenues to augment a company’s existing software stack. This includes integrations with PLM systems and external design analysis and simulation platforms, as well as export of design data in formats compatible with traditional CAD or even direct export of 3D printing slicing data.

It also comes equipped with a command line interface that allows users to run nTopology workflows through scripts in a programmatic environment, automating and scaling design processes for mass customization applications.

The growth of nTopology over the past three years has been aided by a number of funding rounds, as nTopology raised $40 million in Series C in 2020, as well as a further $65 million at the end of last year.

The firm has since partnered with 3D printer manufacturer Stratasys to develop the FDM Fixture Generator, an automation tool for streamlining the design of jigs, fixtures, and other tooling.

The road ahead for nTopology

As is evidenced by its milestones thus far, the company is continuously developing updates and upgrades for its generative design platform.

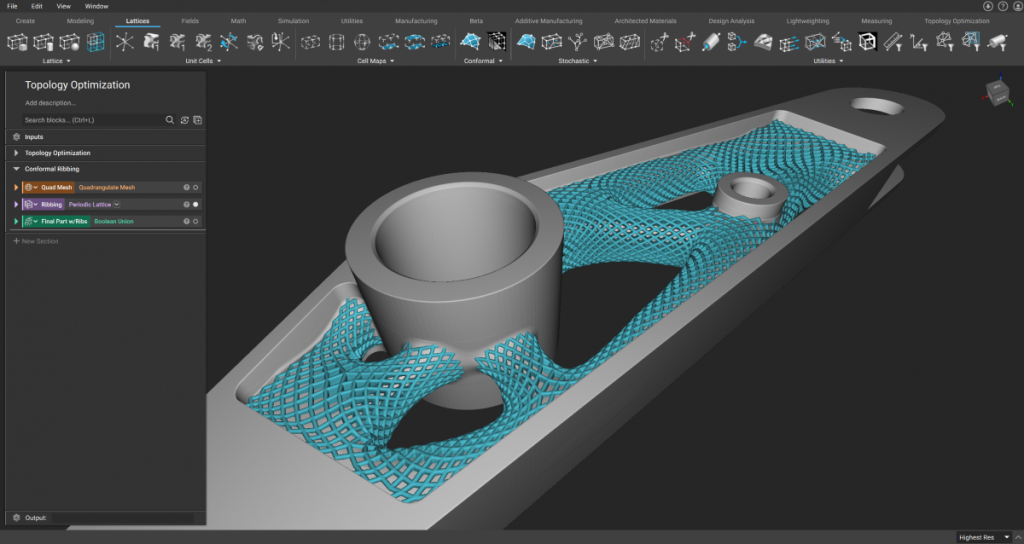

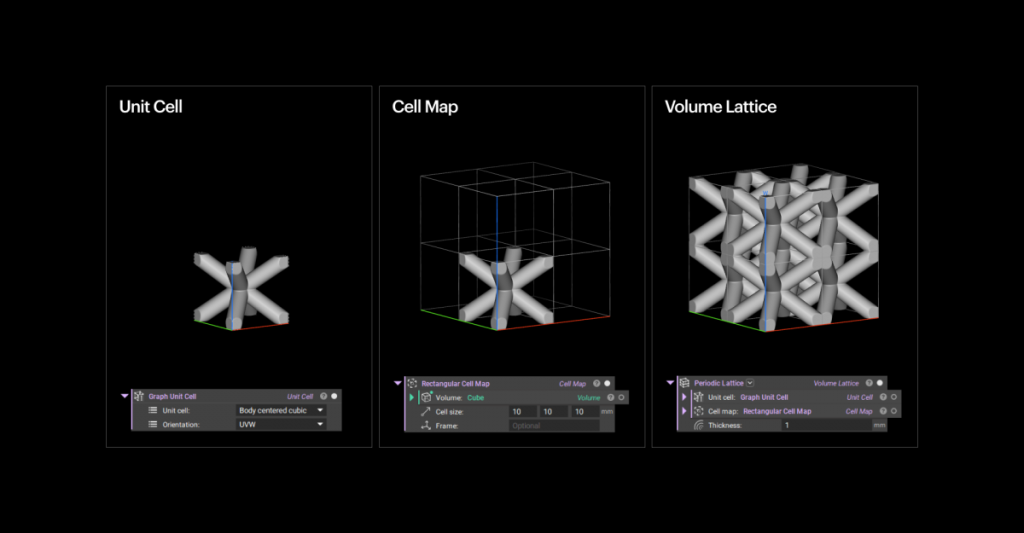

Most recently, nTopology debuted its third-generation lattice design tools, which are intended to provide customers with a quick and easy way of generating complex 3D printable lattice structures. The upgrade involved splitting the lattice generation process into three individual steps, giving users control over each aspect of lattice design: selecting a unit cell, defining the cell map, and fine-tuning the lattice parameters.

One of the major benefits was seen in performance as generating a lattice with over 50,000 unit cells used to take up to 60 seconds, but now it can be built in close to real-time.

As well as introducing the new features, the release laid down a basic architecture for the creation of several new follow-on optimization tools.

The upcoming field-driven optimization capability will enable customers to automatically optimize their lattice structures for specific engineering requirements, including targeted stiffnesses or weights. Users will also be able to sketch their own custom graph unit cells if the unit cell type they need isn’t already covered in nTopology.

Finally, the team is working on extending the platform’s conformal lattice generation capabilities to complement the technology’s existing tools. As such, customers will soon be given the ability to design lattice cell maps that follow the shape of any organic surface or volume.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the third generation latticing technology in action. Image via nTopology.