Metal 3D printing service bureau Rosswag Engineering has beta-launched what is believed to be the world’s first marketplace for trading laser powder bed fusion (LPBF) process parameters.

The AddiMap project was started in partnership with software firm NuCOS back in 2020. The goal was to create a centralized B2B platform where additive manufacturing enterprises can share materials, parameters, data, and services related to metal 3D printing, all in a bid to accelerate the industrialization of the technology.

The partners are now beta-testing the first service of the joint AddiMap platform, where users can buy and sell tried and tested materials data and process parameter sets for LPBF 3D printers.

Streamlining process parameter development

Based in Germany, Rosswag boasts a wide-reaching portfolio of 3D printing products and services, including metal powders, high-performance components, and material and parameter qualification services. Since its inception, the firm has 3D printed more than 60,000 metal parts and qualified more than 40 PBF materials for clients.

Leveraging its expertise, the company developed the marketplace to ensure more market participants could utilize the benefits of process parameter optimization in a more accessible manner.

Validating the productivity of a specific parameter set in-house can be a very tedious and costly process, especially when it comes to smaller enterprises. It’s not uncommon for companies to spend weeks and months developing and carrying out their own series of tests and analyses. According to Rosswag, the associated R&D costs can also exceed €10,000 in some cases.

With the AddiMap marketplace, the idea is to completely revamp the process parameter development workflow. Instead of setting up in-house studies, users simply search, buy, and download the parameter sets they need in a matter of minutes at much lower costs. The two-step process involves defining the material by chemical composition or material number, and specifying the LPBF system that will be used. AddiMap will then search its database for a matching parameter set.

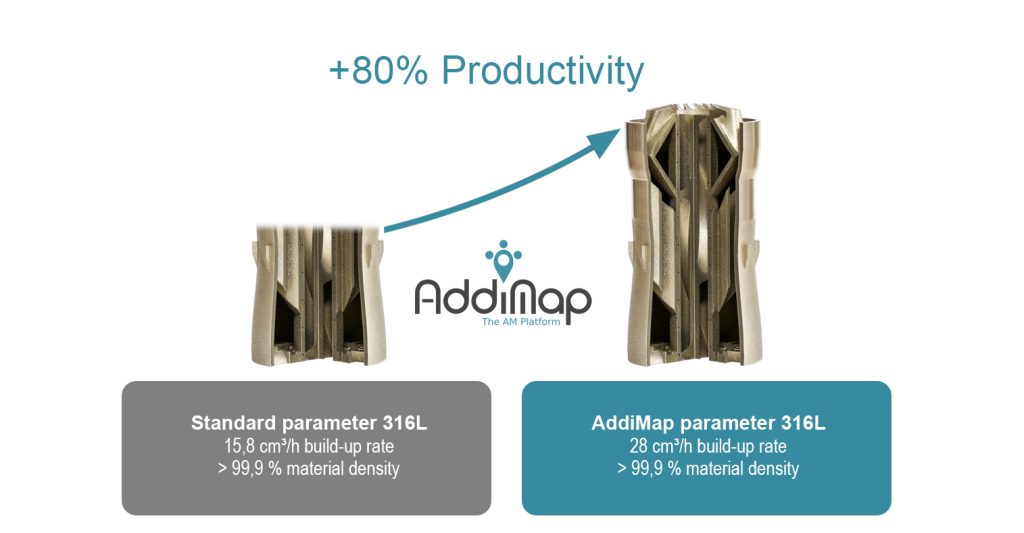

Rosswag states that beyond the cost and time savings, customers can also expect significant improvements in terms of productivity. The purchased parameter sets would be developed by companies with better R&D capabilities and greater expertise in the field, reliably allowing for much higher build rates when compared to generic out-the-box parameter sets.

Towards additive manufacturing industrialization

On the other side of the coin, the marketplace also provides an additional revenue stream for data providing companies with a focus on R&D. Rather than sitting on an otherwise unused dataset, they can capitalize on their work and recoup R&D costs through AddiMap sales.

Ultimately, AddiMap is a place to stand on the shoulders of giants, meaning companies may no longer have to solve problems that have been solved many times before. This allows additive manufacturing newcomers to spend their resources more wisely, focusing on novel applications and pushing 3D printing towards greater industrialization.

This theme of industrialization is a common thread throughout the sector as a whole. Just last month, automotive firm BMW announced the success of its Industrialisation and Digitalisation of Additive Manufacturing (IDAM) project. Launched three years ago, the initiative has established two automotive 3D printing production lines in Bonn and Munich. Build for automated high-volume production, the sites are now capable of fabricating around 50,000 parts per year.

Elsewhere, software developer Materialise recently announced its new CO-AM open software platform, a comprehensive 3D printing process management tool expected to accelerate industrialization. The cloud-based program is aimed at high-volume manufacturers and grants access to a wide variety of software tools for planning, managing, and optimizing the industrial 3D printing workflow.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows an SLM 280 3D printer at a Rosswag facility. Photo via Rosswag Engineering.