An international study published in Nature Communications is paving the way for more effective use of biocompatible materials, particularly in restoring cartilage. Cartilage is notoriously difficult to restore, as it requires a balance of mechanical strength and flexibility that are difficult to reproduce. However, researchers at the Technical University of Munich (TUM) are testing a new material that is a combination of hydrogels and microfiber scaffolding that could change that.

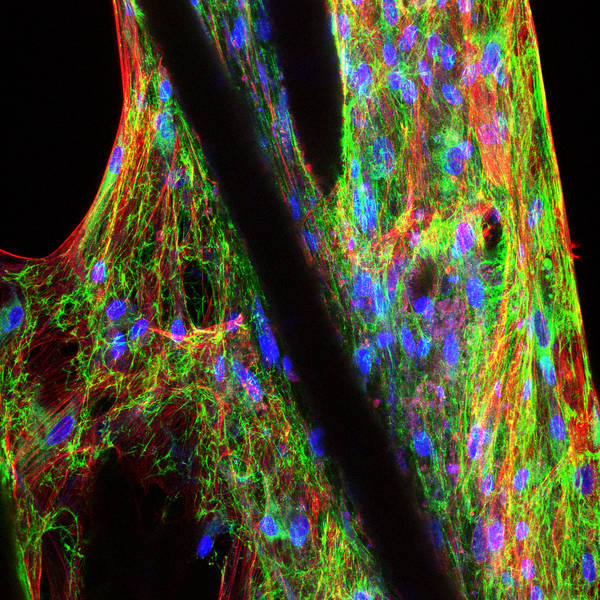

So far, their tests have showed that the material is comparable to knee-joint tissue. With its mixture of stiffness and elasticity, it has the ability to support the cross-linking and growth of human cartilage cells. TUM researchers hope that their research will have an impact on the larger field of soft-tissue engineering. Joint repair, breast reconstruction, as well as heart tissue engineering could also benefit from this research. Professor Dietmar W. Hutmacher, one of the lead authors of the Nature Communications study says, “We need to implant the scaffolding under the muscle, and fiber-reinforced hydrogel could prove critical in regenerating large volumes of breast tissue, as well as the biomechanically highly loaded heart valves.”

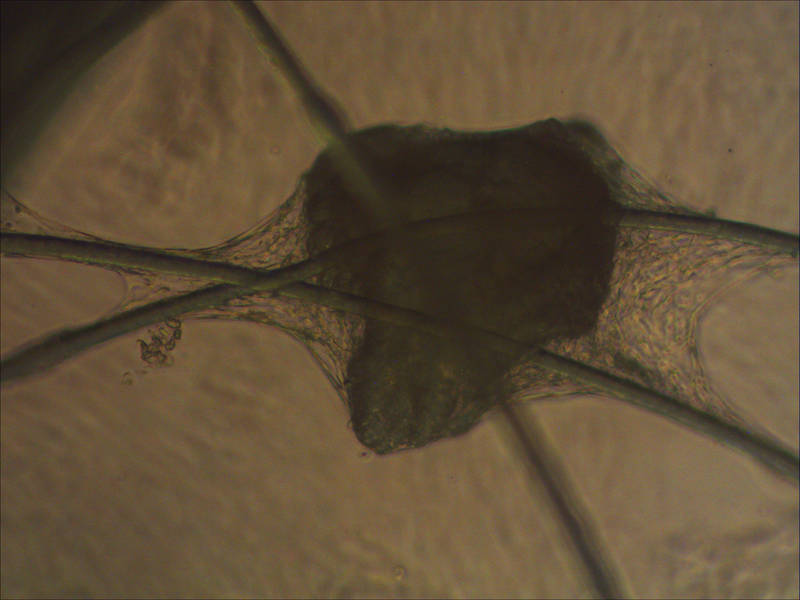

The new 3D printing process of electrospinning, similar to the process used in Liquidity’s Naked Filter, has really opened the door for biomedical researchers. This process allows for the right balance of firmness and room for the cell growth needed. Prof. Hutmacher explains, “It allows us to more closely imitate nature’s way of building joint cartilage, which means reinforcing a soft gel – proteoglycans or, in our case, a biocompatible hydrogel – with a network of very thin fibers.” Replicating nature’s weaving process for tissue, scaffolding filaments using melt electrospinning can now be as thin as 5mm in diameter. This is a 20-fold improvement over other more conventional methods for developing a biocompatible cartilage material.

The study, based on the combined research of TUM, and collaborators in the Netherlands, UK and Australia focused on a wide range of tools for their investigation. All of the mechanical testing, design and fabrication research points in what Hutmacher calls a “breakthrough” direction. Now, that their computer model of the hydrogel-fiber composite material is in place, the next step is to research all possible applications for this exciting biomedical material.