Researchers from the Institute of Materials Science and Technology at TU Wien in Vienna have developed a novel process for 3D printing artificial biological tissue.

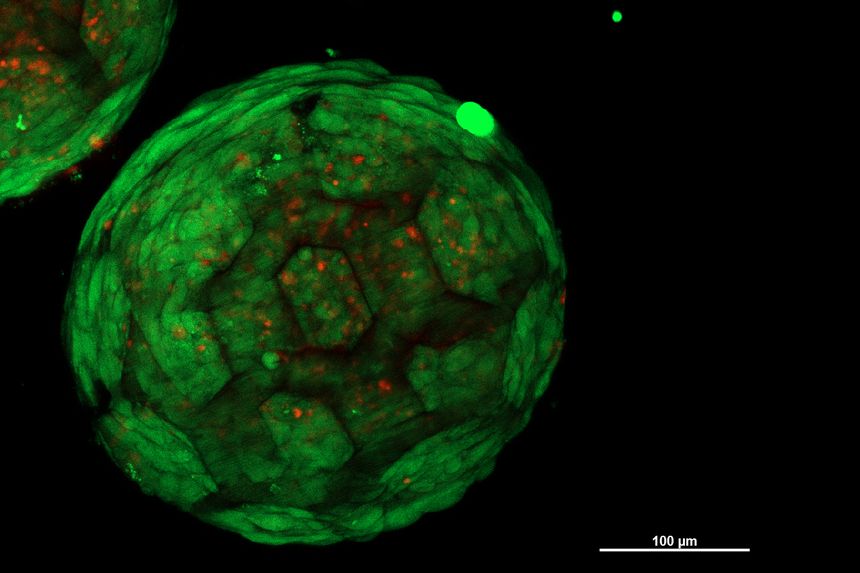

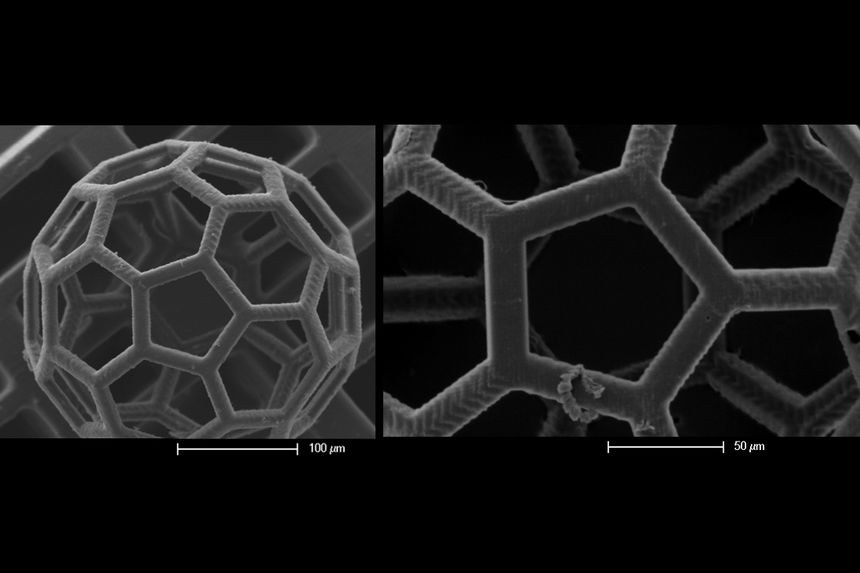

This approach leverages high-resolution SLA 3D printing to produce tiny, porous spheres from biocompatible and degradable plastic. These 3D printed football-shaped scaffolds, or spheroids, are then colonized with stem cells and arranged in specific geometries.

In the study, which was published in Acta Biomaterialia, the TU Wien researchers demonstrated that the cells can then be combined to form living cartilage tissue. A strong connective tissue found in various parts of the body to protect joints and bones, cartilage is notoriously difficult to fabricate with conventional methods.

The research team hopes that its findings will open up new possibilities for creating artificial tissue to replace damaged cartilage in medical procedures.

The new approach is not limited to cartilage tissue, and could be used to tailor different kinds of larger tissues such as bone tissue. Key challenges, such as the incorporation of blood vessels into larger 3D printed tissue, would need to be overcome before the researcher’s 3D printing methodology can be expanded into more complex medical applications.

“An initial goal would be to produce small, tailor-made pieces of cartilage tissue that can be inserted into existing cartilage material after an injury,” stated study author Oliver Kopinski-Grünwald.

“In any case, we have now been able to show that our method for producing cartilage tissue using spherical micro-scaffolds works in principle and has decisive advantages over other technologies.”

Fabricating cartilage tissue with 3D printed cell scaffolds

According to Kopinski-Grünwald, the main challenge when cultivating cartilage tissue from stem cells is the usual lack of control over its final shape. “This is also due to the fact that such stem cell clumps change their shape over time and often shrink,” explained Kopinski-Grünwald.

The TU Wien team’s novel approach is said to overcome this challenge with specially developed laser-based high-resolution resin 3D printers. Two-photon polymerization was used to fabricate the microscopic spherical scaffold structures, which have a diameter of just one third of a millimeter, or 333 µm.

The team then added differentiated stem cells into the miniature football-shaped structures. These cells can no longer develop into any type of tissue, instead being instructed to form a specific type of tissue, in this case cartilage.

Once added to the 3D printed scaffolds, the cells quickly fill the small volume. According to Professor Aleksandr Ovsianikov, head of the 3D Printing and Biofabrication research group at TU Wien, this allowed the team to reliably produce tissue elements with evenly distributed and high-density cell formations.

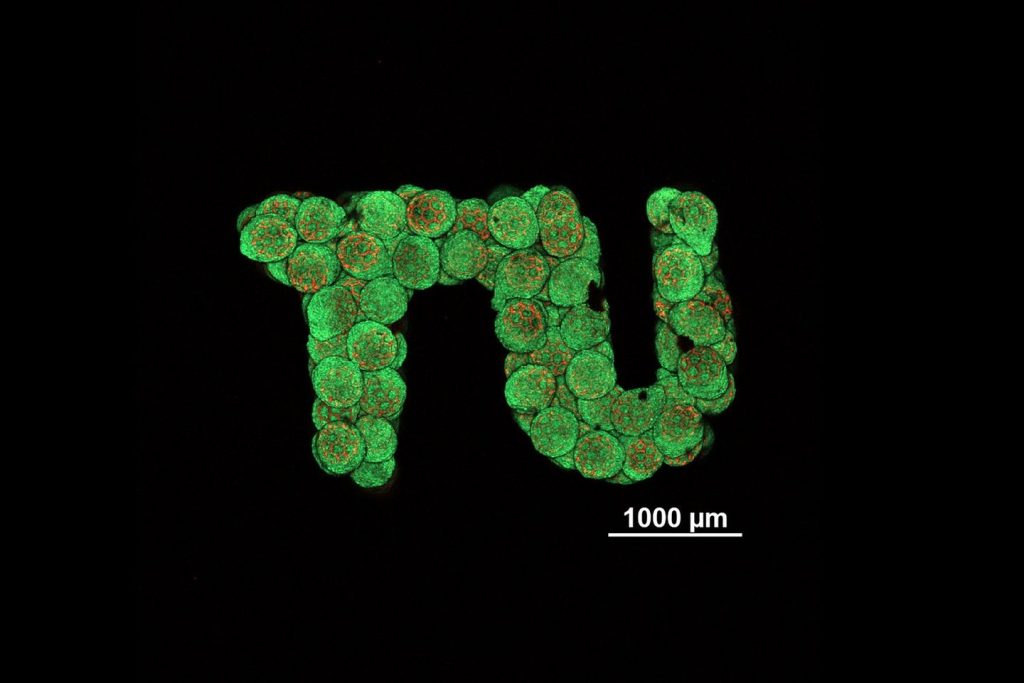

The 3D printed cell support structures ultimately form compact building blocks that can then be assembled into any required shape or geometry.

The spherical scaffolds provide stability to the overall structure as the tissue matures. 3D printed in biodegradable plastic, the support structure then dissolves over the space of a few months, leaving behind the complete tissue in its final form.

While differentiated stem cells are already utilized in various medical applications, the use of cartilage cells in the construction of larger tissue poses challenges. For instance, cartilage tissue cells form a pronounced extracellular matrix. This mesh-like structure is located between the cells, and often prevents different cell spheroids from growing together in the desired way.

The TU Wien researchers’ process successfully overcomes this obstacle. The team is reportedly the first to combine cells from different spheroids into uniform, homogenous, and completely closed cartilage tissue.

“Under the microscope, you can see very clearly: neighboring spheroids grow together, the cells migrate from one spheroid to the other and vice versa, they connect seamlessly and result in a closed structure without any cavities – in contrast to other methods that have been used so far, in which visible interfaces remain between neighboring cell clumps,” noted Kopinski-Grünwald.

3D printing artificial human tissue

3D printing human tissue for medical applications is certainly a growing field. 3D expert surveys on 3D printing trends and the future of 3D printing highlighted the medical industry as being a sector which will continue to experience significant 3D printing innovation.

A team of scientists from University of Sydney and the Children’s Medical Research Institute (CMRI) at Westmead leveraged 3D photolithographic printing to create functional human tissue capable of accurately mimicking human organs.

The researchers used cell culture and bioengineering techniques to instruct stem cells from blood and skin cells to become specialized. The specialized cells were then used to fabricate 3D printed organ structures. The next step of the research will see the team focus on developing their unique process to advance the field of regenerative medicine, and enable new treatments for a range of diseases.

Elsewhere, leading US additive manufacturing company 3D Systems last year announced its Regenerative Tissue Program (RPT). This strategic initiative seeks to develop and commercialize 3D bioprinted human tissue. The program builds on the company’s in house healthcare products and expertise, such as Virtual Surgical Planning (VSP).

The first RPT product to be developed related to patient-specific regenerative breast tissue, designed to meet growing demand in breast cancer treatment. Leveraging VSP, 3D Systems says that it can design and produce bio-integrative scaffolds that match a patient’s anatomy and physiology.

As such, the personalized 3D printed regenerative breast tissue is said to improve long-term outcomes with an optimized patient experience.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows a 3D printed spheroid, filled with living cells. Image via TU Wien.