Researchers from the Massachusetts Institute of Technology (MIT) have published a new study demonstrating the benefits of Liquid Metal Printing (LMP) for large-scale construction and architecture applications.

The team’s LMP 3D printing approach deposits molten aluminum onto a bed of small glass beads, with the aluminum quickly hardening into a 3D structure. This process sacrifices surface resolution and precision for speed. LMP reportedly fabricates 3D printed metal structures 10 times faster and at lower costs than alternative metal additive manufacturing techniques.

While LMP is not a new technology, the researchers state that this study is the first to demonstrate its value in rapidly fabricating large-scale parts for architecture and construction applications.

The study, published by the Association for Computer Aided Design in Architecture (ACADIA), also argues that LMP offers sustainability advantages in large-format metal 3D printing. The MIT team points to LMP as being well suited to rapid prototyping and production using recycled or scrap metal.

The researchers 3D printed a range of aluminum structures to support their hypothesis, including frames for tables and chairs. The study highlights that components made with LMP can be combined with additional materials and post-processing steps to create functional furniture.

“This is a completely different direction in how we think about metal manufacturing that has some huge advantages. It has downsides, too. But most of our built world — the things around us like tables, chairs, and buildings — doesn’t need extremely high resolution,” commented Skylar Tibbits, a senior author of the study and associate professor at MIT’s Department of Architecture. “Speed and scale, and also repeatability and energy consumption, are all important metrics.”

LMP speeds up large-scale metal AM

Wire Arc Additive Manufacturing (WAAM) is an existing metal 3D printing technology that is prominent in the construction and architecture sector. Like LMP, WAAM can quickly fabricate large, low-resolution structures. However, WAAM-produced parts can be susceptible to warping and cracking as remelting is often required during the 3D printing process.

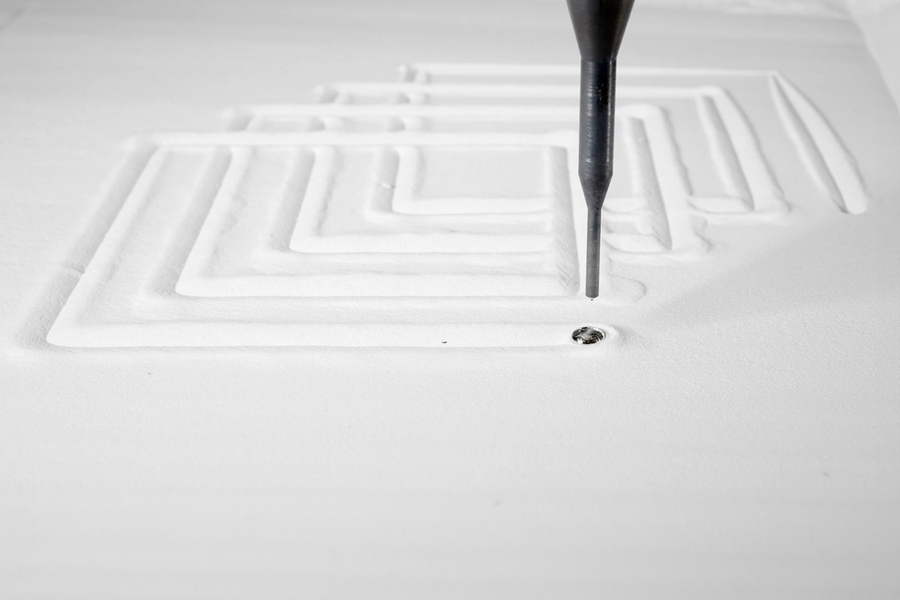

LMP reportedly overcomes these challenges, as the metal remains molten throughout the 3D printing process. The MIT team’s LMP is optimized for use with aluminum. The 3D printer extrudes molten aluminum through a ceramic nozzle at high speeds into a bed of glass beds. This process can reportedly 3D print large-scale metal parts in seconds, with the molten aluminum cooling and hardening in several minutes.

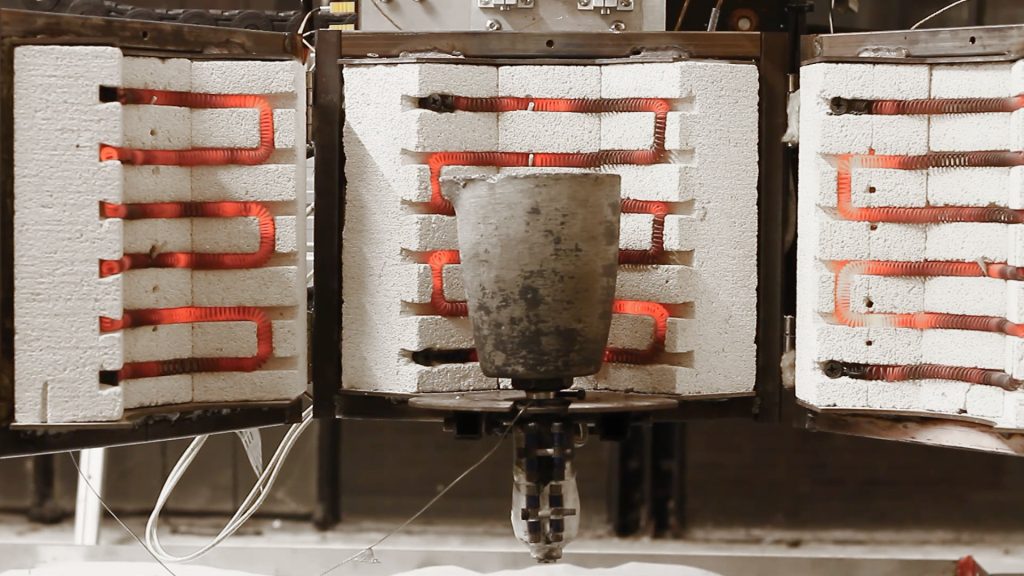

During this process aluminum, chosen for its popularity in construction and the ease at which it can be recycled, is heated to 700℃ in an electric furnace. After being held at high temperature in a graphite crucible the metal, now molten, is gravity-fed through the nozzle.

As the molten material is injected directly into a granular substance, no supports are required during LMP 3D printing, allowing large-scale structures to be quickly and easily fabricated.

During 3D printing, the LMP nozzle is pushed into the glass bead powder, meaning that users can’t watch the molten aluminum be deposited. As such, the team developed a numerical model that simulates the extrusion process, estimating the amount of material deposited at any given time.

In the study, the researchers used their LMP to rapidly produce metal furniture frames with variable thicknesses. These frames were durable enough to withstand machining processes such as milling and boring. Combining LMP with these post-processing methods, the MIT team fabricated full-scale 3D printed tables and chairs.

The team concluded that LMP holds significant potential in the construction and architecture industries both as a tool for prototyping, and as a form of rapid, low-cost, large-scale production.

Looking to the future, the team will continue to iterate its LMP technology to enable nozzle heating, which would help to prevent clogging. The researchers also hope to achieve better control over the flow of molten material.

Ultimately, it is hoped that MIT’s LMP 3D printer can be made more accessible to allow users to easily 3D print large-scale parts from recycled metal.

“If we could make this machine something that people could actually use to melt down recycled aluminum and print parts, that would be a game-changer in metal manufacturing,” explained Tibbits. “Right now, it is not reliable enough to do that, but that’s the goal.”

Developments in Liquid Metal Printing

Although the first to demonstrate potential in large-scale metal additive manufacturing applications, the MIT researchers are not the first to leverage LMP 3D printing.

Back in 2018, researchers at Oregon State University (OSU) harnessed Liquid Metal Printing to fabricate small and flexible 3D printed electrical circuits. Combining a liquid metal alloy with nickel, the team successfully created a conductive metal paste that was 3D printed directly onto a flexible surface, creating two complete circuits that overlapped without touching.

More recently, in 2022 Manufacturing system and machine tool developer GROB-WERKE (GROB) entered the 3D printer market with the launch of its GMP300 LMP 3D printer. This system was designed to enable rapid production of near-net-shape parts from metal wire feedstock in an economical, material-efficient process.

Advertised as offering a higher build-up rate than Powder Bed Fusion (PBF) and better resolution than Directed Energy Deposition (DED), the GMP300 is targeted towards applications in the metalworking sector. Possessing a 300 x 300 x 300 mm³ build volume, this LPM 3D printer incorporates three-axis kinematics, a top axis speed of 30m/min, and a build chamber that operates under an inert atmosphere.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows the LMP 3D printer’s nozzle heating assembly. Photo by Self Assembly Lab.