Manufacturing system and machine tool developer GROB-WERKE (GROB) has announced its entry into the 3D printing industry with the launch of its new GMP300 machine.

GROB’s debut Liquid Metal Printing (LMP) system is designed to enable the rapid creation of near-net-shape parts from wire feedstock, in an economical, material-efficient way. Billed as having a higher build-up rate than Powder Bed Fusion (PBF) and a better resolution than Directed Energy Deposition (DED), it’s believed the technology could help drive 3D printing’s adoption in the metalworking sector.

GROB’s segway into 3D printing

Based in Munich, but with production facilities in Brazil, China, Italy and the USA as well, GROB has been a manufacturing product and service provider since 1926. Over its nearly 100-year existence, the firm has built up a broad portfolio of machines, including turn-key plants, multi-axis milling systems and assembly stations.

To-date, this offering has allowed GROB to address the needs of clients in the areas such as the highly-regulated aerospace and automotive sectors, as well as those in medical, energy and mechanical engineering. Leveraging its universal machining centers, for instance, the company says it’s possible to create everything from connectors like steering knuckles, to full-blown cylinder blocks and crankcases.

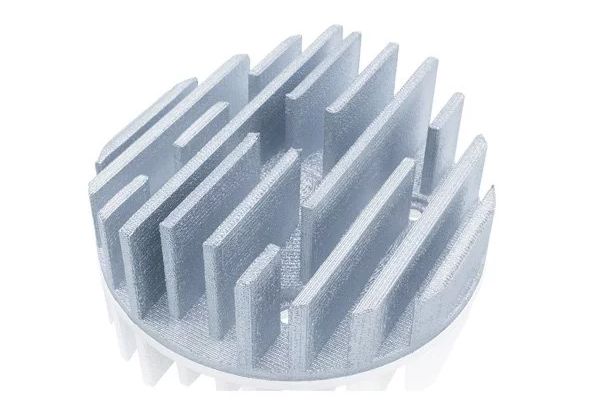

While GROB hasn’t traditionally had a 3D printing offering, the launch of the GMP300, a machine that enables the creation of holders, clamping rings, distributors and heat sinks, could now open its technologies to a new metalworking clientele.

Targeting metalworkers with LMP

According to GROB, PBF is currently the most commonly-used additive manufacturing process in the metalworking sector. However, the firm also highlights how the technology has multiple drawbacks that stop it being embraced on a wider scale there, including the cost of materials, powder management requirements and slow build-up rates.

To get around these issues, which prevent what it calls the “economically-viable use” of PBF systems, GROB has unveiled the “future-oriented, economically sound” GMP300. Unlike traditional PBF machines, the new 300 x 300 x 300 mm³ build volume system is wire-fed in a way that not only provides users with material efficiency gains, but allows them to skip the part depowdering process altogether.

“With no powder handling, integration of the system into an existing production line can be carried out without increased safety precautions,” explains Johannes Glasschröder, an Additive Manufacturing Team Leader at GROB-WERKE. “In addition, we envision a great synergy effect for the required post-processing of functional surfaces with our existing portfolio in the machining range.”

Another benefit of switching to LMP, is that it’s a micro-casting technology and not a welding process. As such, GROB says GMP300 adopters can look forward to “having little to no thermal warping,” while enjoying compatibility with non-weldable alloys.

Elsewhere, the new machine features three-axis kinematics, a top axis speed of 30m/min and a build chamber that operates under an inert atmosphere. Together, it’s said these specifications allow the GMP300 to achieve high build-up rates while retaining a consistent part quality level. Moving forwards, GROB therefore believes its system can offer metalworkers a genuine 3D printing alternative to PBF or DED.

Technical specifications and pricing

Below are the technical specifications for the new GMP300 Liquid Metal Printing system. Those interested in ordering the machine can contact GROB for a quote.

| Technology | Liquid Metal Printing |

| Build Volume | 300 x 300 x 300mm3 |

| Positioning Accuracy | 0.015 mm |

| Max Axis Speed | 30 m/min |

| Min/Max Var. Droplet Diameter | 0.4 – 0.7mm |

| Calculated Max. Build-up Rate | 320cm3/h |

| Max Building Panel Heating | 650 °C |

| Control System | Beckhoff TwinCat |

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a render indicating what GROB’s GMP300 3D printer will look like. Image via GROB.