French 3D printer manufacturer QUALUP SAS has released a new system that enables users to closely control material flow as a means of ensuring the production of consistent-quality parts.

Known as the ‘Qu3-HT,’ QUALUP SAS’ printer features a monitoring system that allows users to make sure that filaments flow at a constant rate, and resulting prints aren’t subject to variations that impact on their dimensions, strength or finish.

The machine’s adaptive build volume is also able to heat up more quickly than static equivalents, enabling parts to be rapidly made from high-temperature materials like PEEK or PEKK.

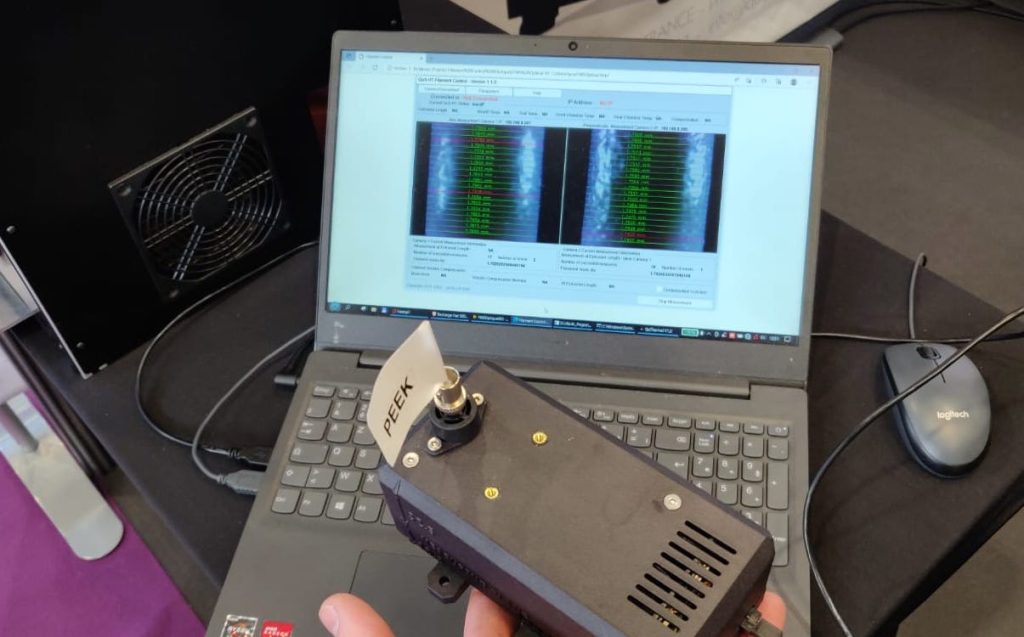

“The filament control [system] integrated into the printer, continuously measures the diameter and ovality of the filament with an accuracy of 0.8µm,” explains Myriam Boichut, President of QUALUP SAS. “The triple objective of this instrument is to continuously compensate for variations in filament diameter in order to have a constant flow rate, the same as that calculated by the Slicer, to guarantee the repeatability and the quality of the parts by means of a print report supplied with each part.”

Ensuring consistent filament flow

During extrusion, many commercial filaments undergo warping within tolerances of around +/-0.05mm. At first glance, this may appear to allow for 3D printing with a high degree of accuracy, but as QUALUP SAS points out, this leaves room for a variation in volume of up to 12% between the material’s maximum and minimum tolerances, making it tricky to ensure the quality and repeatability of resulting parts.

When it comes to heavier-duty polymers like PEEK, PEKK, PEI and PPSU, some material developers even market them as having tolerances of +/- 0.10mm, doubling the chances that they’ll suffer distortion. Such issues are somewhat caused by the way extruders control the rate filament flows at, known as the ‘mm-equivalent,’ which according to QUALUP SAS makes it “impossible to achieve consistent quality.”

To provide manufacturers with greater material control, the firm has therefore come up with a new system that measures the diameter of filaments in two perpendicular planes and calculates their ovality. At the same time, the system queries the Qu3-HT’s motherboard to find out the length of material extruded, before using this data to calculate the amount of compensation needed to ensure part quality.

Once the 3D printer has completed this process, which is carried out at a frequency of 500Hz (or a check every 2s) and an accuracy of 0.8µm, it’s capable of producing a report certifying that two parts printed with the same G-code are identical, something QUALUP SAS says is impossible without measuring a filament’s diameter mid-extrusion.

“We decided to develop this feature a little over two years ago when one of our customers asked us to print stainless steel parts using a process similar to BASF’s Utrafuse 17-4,” adds Boichut. “It was impossible to print correctly with 100% filling, the filament, highly-charged with metal 85/15 ratio. Either there were gaps and porosity, or the nozzle became fouled and caused marks on the part. This innovation has profoundly improved the quality and repeatability of Qu3-HT printed parts, with all materials, especially high-temperature polymers.”

“It is now possible to certify the quality of Filament Fusion printed parts and that two [of the same] parts are identical.”

Introducing a revamped Qu3-HT

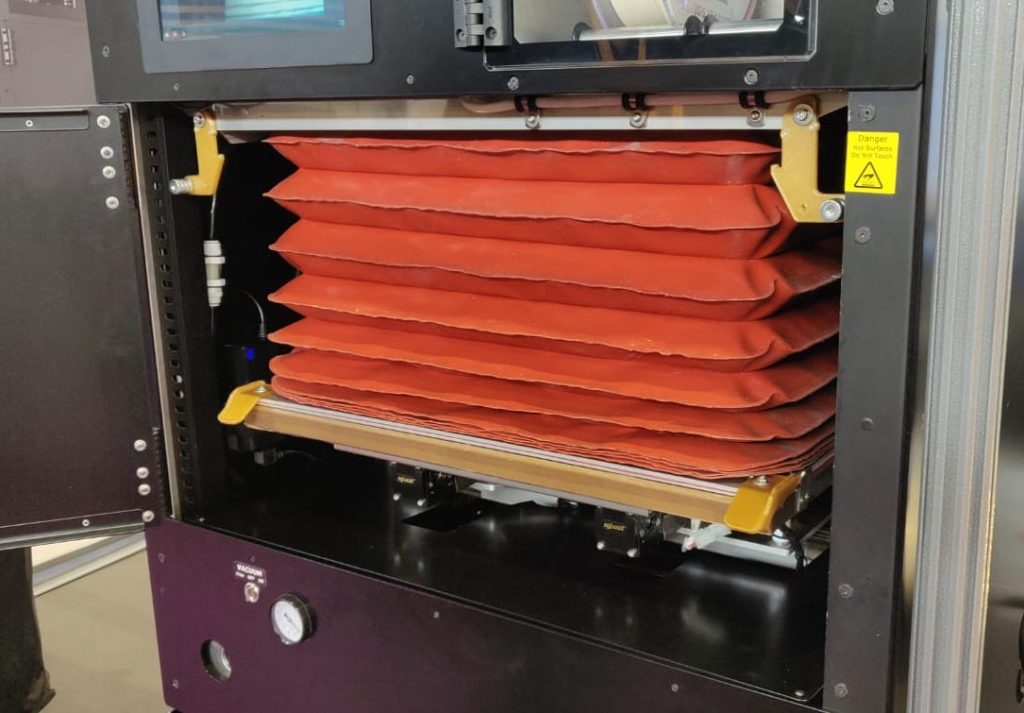

Filament control system aside, the 2022 edition of the Qu3-HT also packs several other features, designed to aid the consistency of users’ parts. One of the most distinctive aspects of the machine’s design is its adaptable bellow-style build chamber, which can not only be set up to print at any temperature between 30°C and 270°C, but physically adjusts to the size of components as they’re produced.

In doing so, the system facilitates the creation of large parts while ensuring that any material used remains at a constant temperature, in a way that further improves build repeatability. The adaptable temperature of the new Qu3-HT’s chamber also enables users to carry out heat treatments such as annealing, crystallization and stress release following print cycles, potentially unlocking lead time savings.

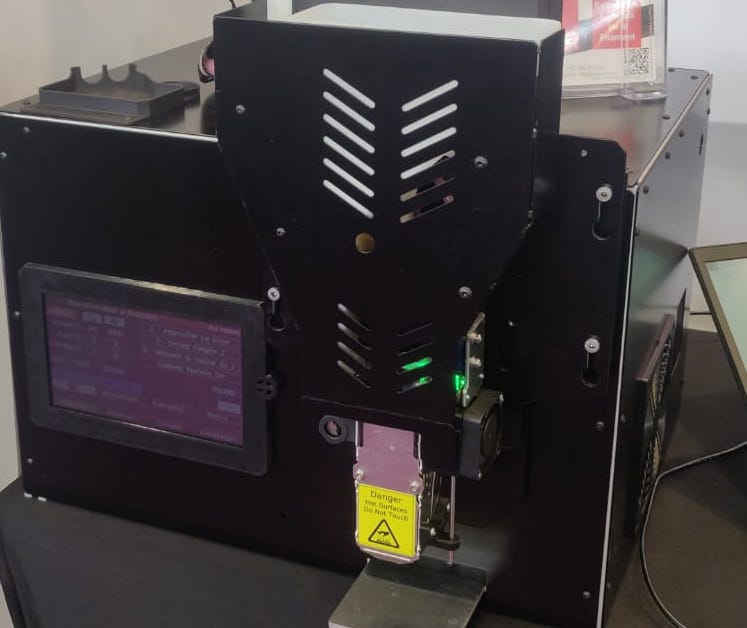

In terms of the machine’s printheads themselves, these are cooled by a pump that circulates 500 liters of water through them per hour, and ensures that they don’t exceed temperatures of 45°C, even after several hours’ printing. The Qu3-HT’s extruders incorporate a set of self-sealing connectors as well, which make maintaining them easier than it’d otherwise be, while protecting users against any fluid leakage.

Elsewhere, for those seeking a custom setup, QUALUP SAS has fitted its latest system with an interchangeable print bed, which can quickly be swapped out (due to its vacuum-secured environment) to unlock compatibility with high-temperature metals. Likewise, the firm offers a pre-setting bench and thermal camera with the Qu3-HT, extras which allow users to precisely calibrate printheads, (to configure flow or PID for example) and analyze the system’s build area with greater detail.

Technical specifications and pricing

Below are the technical specifications for the 2022 edition of the Qu3-HT system. Those interested in either finding out more about the machine or ordering it, can contact QUALUP SAS for a quote.

| Technology | Fused Material Deposition |

| Build Volume | 300 x 250 x 300mm |

| Resolution | Less than 0.01mm (in all three axis) |

| Nozzle Temperature | 300°C to 500°C |

| Bed Temperature | 30°C to 250°C |

| Chamber Temperature | 30°C to 270°C |

| Material Compatibility | PEEK, PEKK, PEI, PPSU, Copper, Aluminum, Ceramic |

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Qu3-HT 3D printer’s bellow system. Photo by Maël Duportal.