Researchers from the Singapore Centre for 3D Printing School of Mechanical and Aerospace Engineering Nanyang Technological University have published a review summarising research on carbon nanotubes (CNT) and their use in 3D printing.

The research paper titled, Directed and On-Demand Alignment of Carbon Nanotube: A Review toward 3D Printing of Electronics, categorizes the alignment methods of carbon nanotubes and summarizes various applications of the material. Furthermore, the paper discusses how the material has been used to develop improved composites and how it can contribute to the development of future devices using 3D printing.

Carbon nanotubes

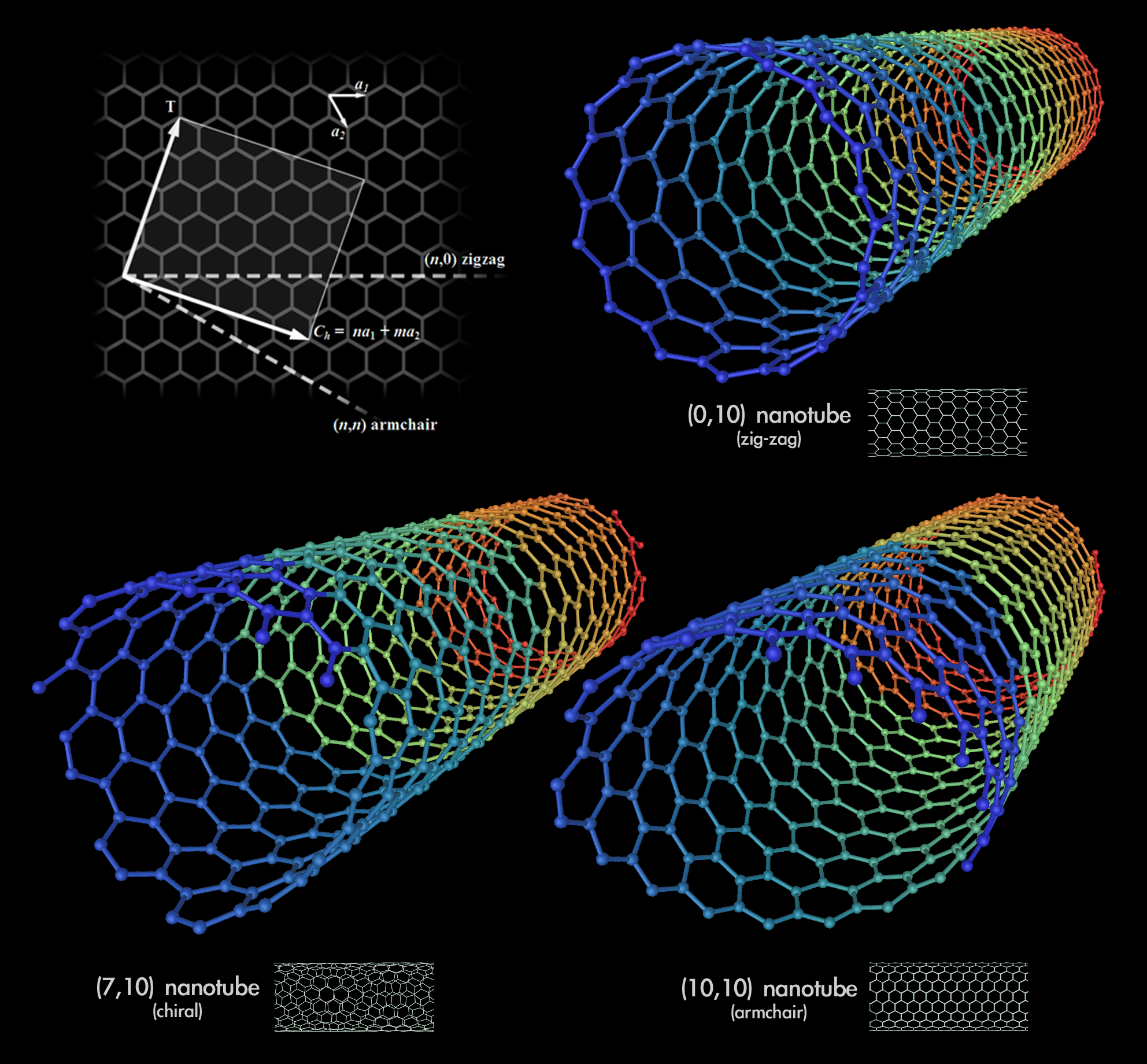

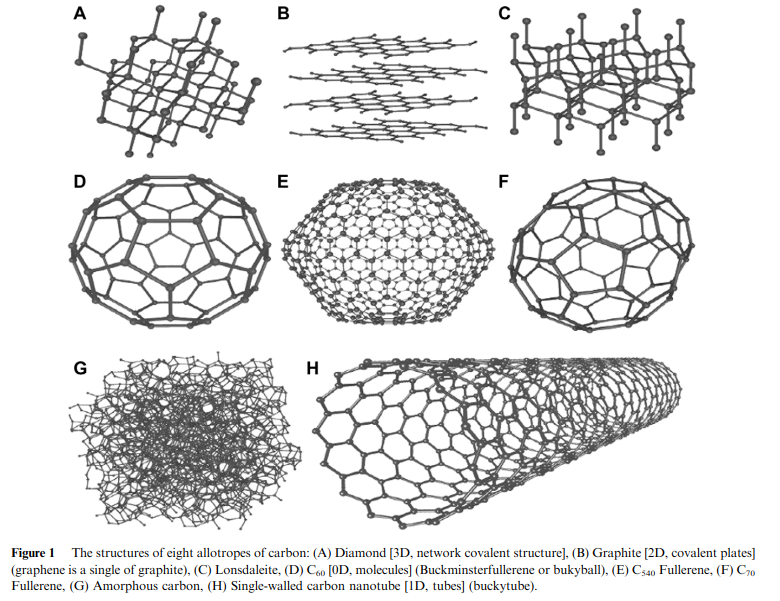

Fullerene is an allotrope of the carbon element. An allotrope is a variation of the physical structure of an element, which means that carbon atoms can combine to form different shapes, and each shape will have particular physical characteristics. For example, diamond is an allotrope of carbon. In diamonds, carbon atoms combine to form a triangular pyramid structure (hence the edged surface of the gemstone). Compared to this the fullerene allotrope has a spherical or tubular structure. A fullerene allotrope which has a cylindrical structure is known as a carbon nanotube.

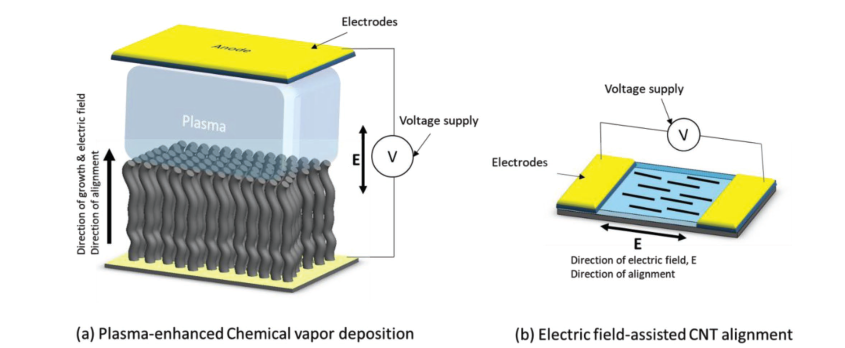

Carbon nanotubes do occur naturally, however, these varieties of CNT are irregular and unstable for them to be used in manufacturing or research. Therefore, for best use of carbon nanotubes, it is important to produce stable and aligned CNT structures. This can be achieved by various methods, eight of which are discussed in the study.

Enhancing common materials

The paper cites various research studies published in recent years which show how CNT can be used to develop composite materials, which have better mechanical, thermal, and conductive properties.

Examples of enhanced composites include CNT-PVA fibers which are “less sensitive to moisture and capable of maintaining high toughness in humid condition.” Another study, reports a CNT-PMMA composite with a 300% increased thermal conductivity.

Furthermore, in 2015, scientists produced an epoxy composite with aligned CNT. The composite had a 22% higher Young modulus and 30% more fracture toughness compared to unaligned CNT. The composite also had a higher percentage of electrical conductivity.

Applications of CNT

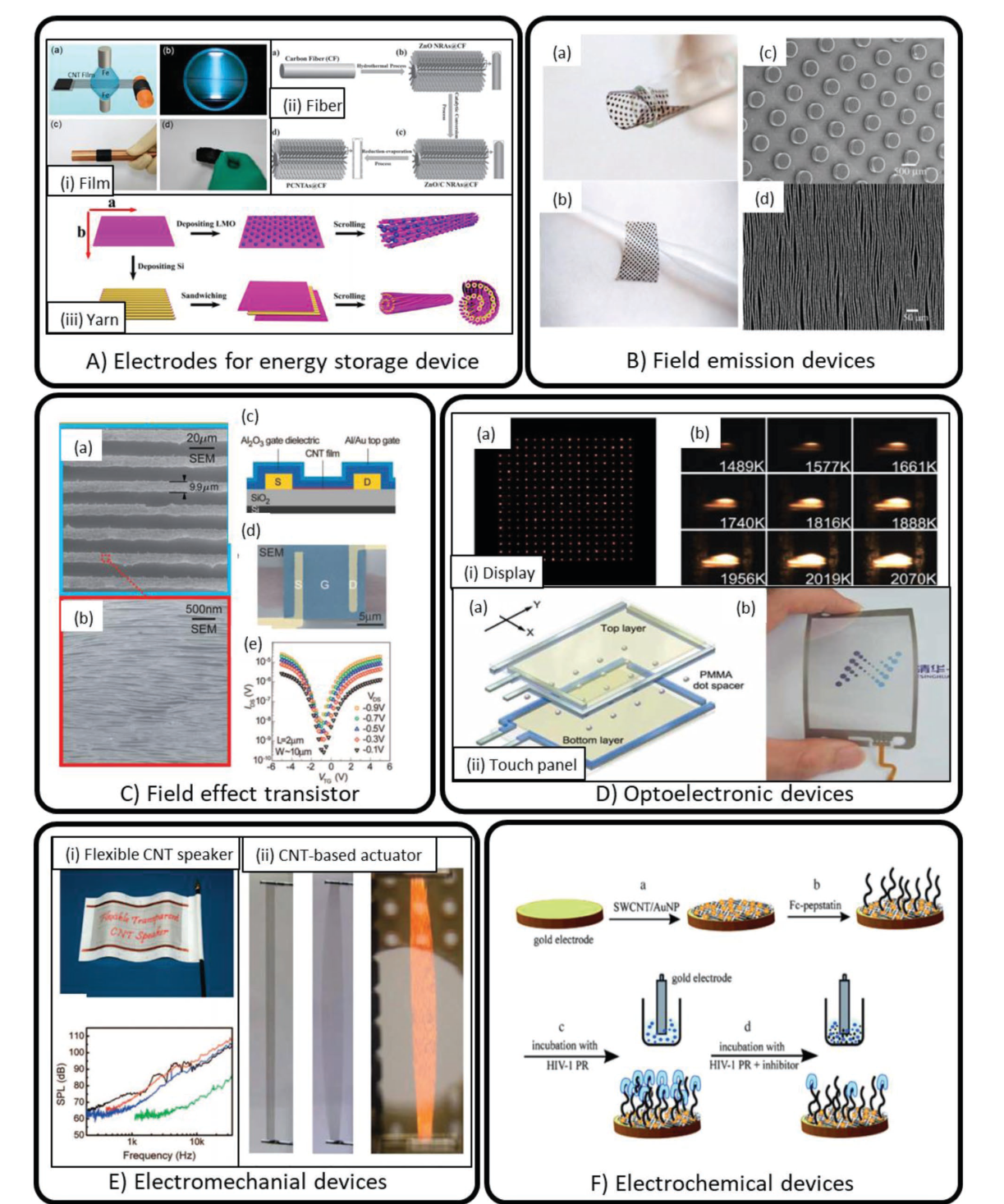

The study also summarised major industrial applications of CNT.

Due to high electrical conductivity CNT composites have been used to make improved batteries. The paper states: “CNTs can be used to produce the high-efficiency silicon Schottky solar cells. Aligned CNTs has been proven to increase the CNT–Si junction density and allows faster transport paths for photocurrent in the oxide. It has been shown that the aligned CNTs can achieve an efficiency of up to 10.5%, which is higher than the counterpart with randomly oriented CNTs network.”

Further uses include field emission devices such as television, and optoelectronics, which includes devices for the detection and control of radiations (such as gamma rays, x-rays, etc).

Apart from electronics other uses include, water purification filters, “Carbon nanotubes membrane is a suitable candidate for filters for purification of water and gas due to its unique cylindrical nanostructure, high mechanical strength, high aspect ratio, and large surface area–volume ratio.”

3D printing carbon nanotubes

In summarising 3D printing, the authors focus on how different 3D printing technologies have been combined with CNT-based composites.

CNT materials have been successfully used to 3D print shape memory polymer for use in soft robotics. Furthermore, CNT materials have also proved to be biocompatible and hence have been used to 3D print tissue scaffolds. The authors write, “bioactive CNTs ink can be used to fabricate biocompatible 2D or 3D hybrid tissue construct with good electrical property for monitoring application.”

The study concludes, “many CNTs alignment techniques have been developed and aligned CNTs devices have been widely used in various fields.

“Future work on CNTs alignment should be focusing on developing techniques that are scalable and can be integrated into existing fabricating processes such as 3D printing.”

The research discussed in this article is titled, Directed and On-Demand Alignment of Carbon Nanotube: A Review toward 3D Printing of Electronics. It was published in the Advanced Materials Interfaces journal and was jointly authored by Guo Liang Goh, Shweta Agarwala, and Wai Yee Yeong.

Nominations for 3D Printing Awards 2019 are open. Please let us know about the best application of 3D printing.

For more news on 3D printing technology subscribe to our 3D printing newsletter. You can also visit us on Facebook and Twitter.

If you are looking for a job, please visit our 3D Printing Jobs site.

Featured image shows a visual representation of different types of carbon nanotubes. Image via Wikimedia Commons.