The advantages of additive manufacturing as a viable process for the production of low number series of complex metal parts are becoming clearer to the advanced manufacturing industry. Thus, more and more companies are introducing next generation products to cater to growing metal powder demand. This is the case for Nanosteel, a company operating in the field of nano-structured steel materials design.

The Providence (RI) based enterprise just launched its first powders designed specifically for binder jetting 3D printing process. These materials, known as BLDRmetal™ J-10 and BLDRmetal™ J-11, were developed to enable the 3D printing of components for highly abrasive environments that can benefit from additive manufacturing’s ability to eliminate tooling, create advanced geometries, and build custom parts on demand.

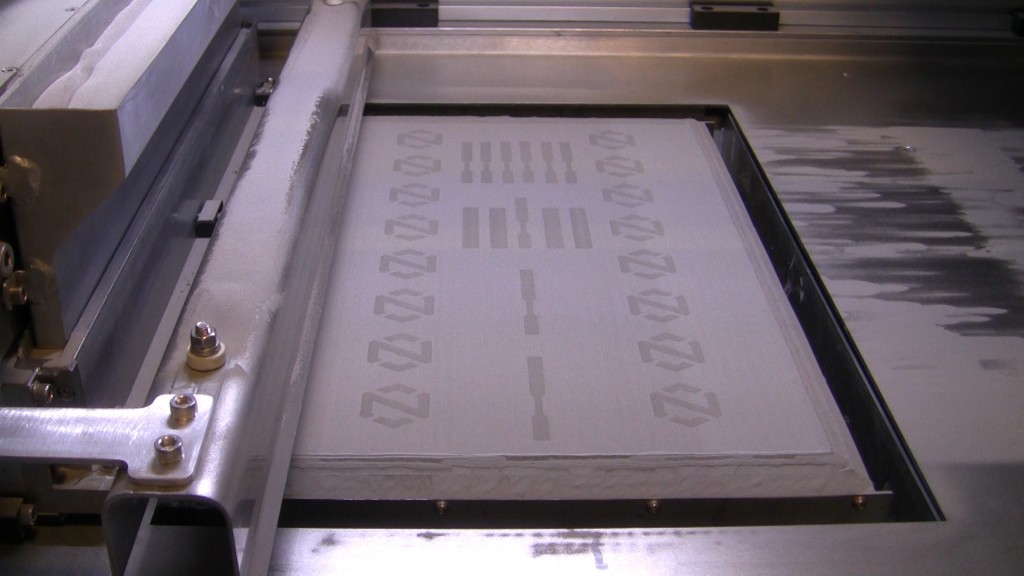

Binder jetting is generally more affordable than metal powder fusion AM (SLM, DMLS, EBM) for larger parts and parts built in small number series; however, this process requires extensive post-processing. The powder particles are first glued together with a binder and subsequently the green parts are sintered in a kiln, before further post-processing (metal infiltration).

“These first BLDRmetal powders offer compelling alternatives to existing materials for the binder jet printing process,” said Harald Lemke, General Manager and Vice President of Engineered Powders at NanoSteel. “The company’s entry into the market enhances the applicability of binder jet printing by enabling the additive manufacturing of high-complexity, lower-cost components with exceptional wear performance.” The binder jetting process is well suited for cost effectively producing industrial metal parts due to the faster building speed.

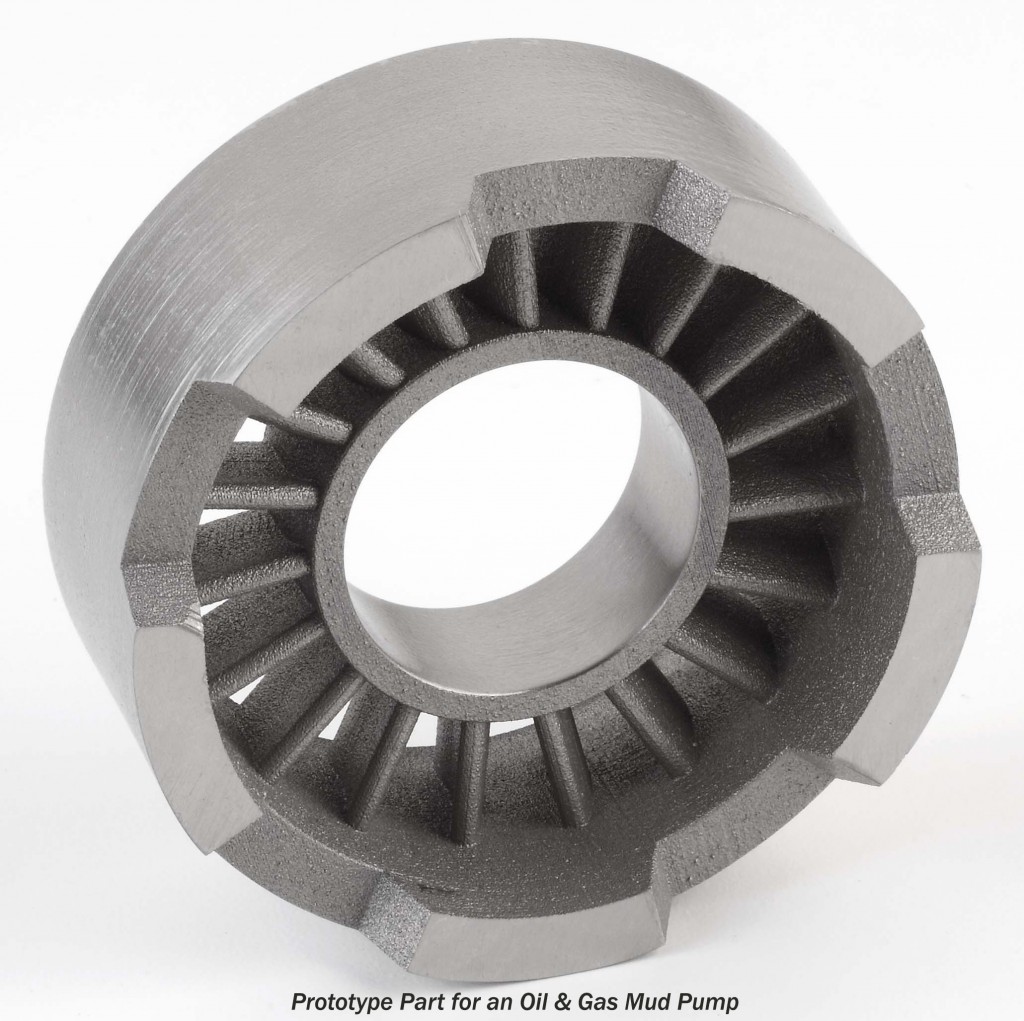

Nanosteel reported that the industrial components made using bronze infiltrated J-10 feature twice the elongation and three times the wear and impact resistance of an equivalently infiltrated 420 stainless steel. The BLDRmetal product line of binder jet powders also includes J-11, which is designed for extreme wear low-impact applications. Components made with J-11 provide ten times the wear resistance of an equivalently infiltrated 420 stainless steel. These enhanced performances are made possible by the combination of complex metallic phases that provide wear resistance and a steel matrix that delivers ductility and toughness.

The powder manufacturer worked with 3DX Industries, an additive manufacturing service provider that uses ExOne’s metal 3D printer range. The large size M-Flex machine was used to 3D print a security tool used by a global avionics company for removing and replacing aircraft panels. In this commercial application, the tools made with J-10 lasted 5 times longer than the previous solution, significantly decreasing the risk of delays in servicing the aircraft. “The NanoSteel solution enabled us to create a tool that delivered the durability and reliability the customer required in a fast turnaround environment,” said Roger Janssen, President and CEO of 3DX. The avionics service team is planning further adoption of this new technology across their global operation.

These are the first in the company’s portfolio of BLDRmetal powders for hard metal applications that will include new products for each of the current metal 3D printing processes. BLDRmetal J-10 and BLDRmetal J-11 are currently intended for applications in industries such as oil & gas, tool & die, and energy in applications such as drilling and pump components, molds, and dies. As binder jetting implementation becomes more common in these fields, more varied application are likely to follow.