Researchers from the University of Illinois Urbana-Champaign and the Beckman Institute for Advanced Science and Technology have developed a novel method for multi-color 3D printing.

Unlike conventional multi-color 3D printing approaches which require multiple materials, this method only requires a single ink. This is said to make the new process more efficient and sustainable.

Drawing inspiration from color-changing chameleons, the team’s UV-assisted-ink-writing approach allows structural colors to be altered “on the fly” during 3D printing.

By changing the strength of UV-light while 3D printing, the researchers were able to achieve a wide range of colors. The colors of the 3D printed material were successfully programmed to reflect a wide spectrum of visible light.

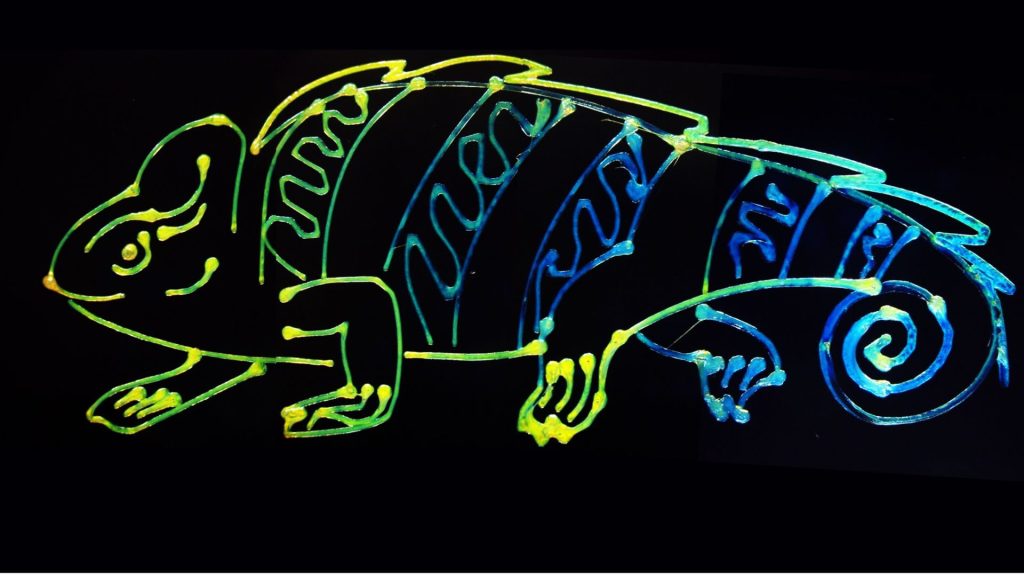

To demonstrate their findings, the researchers created colorful 3D printed art pieces, including a chameleon image and a recreation of Vincent Van Gogh’s “Starry Night” painting. Both pieces showcase the broad spectrum of yellows, green and blues achievable with a single ink.

This new multi-color 3D printing process is said to offer potential for creating new types of sensors, biomedical applications, and in other multi-color manufacturing use-cases.

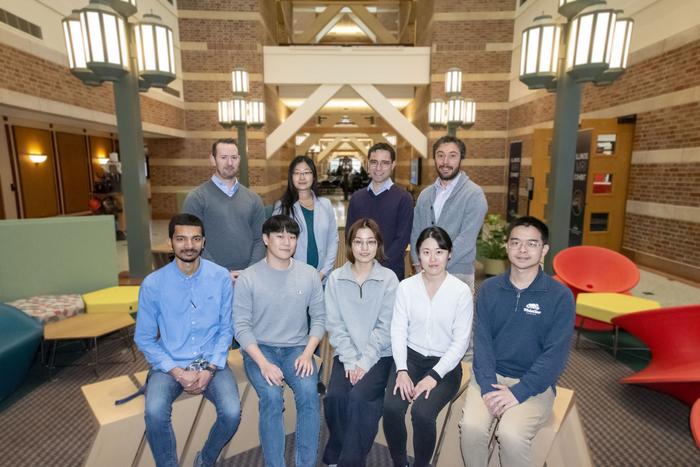

“By designing new chemistries and printing processes, we can modulate structural color on the fly to produce color gradients not possible before,” stated Ying Diao, associate professor of chemistry and chemical and biomolecular engineering at the University of Illinois Urbana-Champaign and a researcher at the Beckman Institute for Advanced Science and Technology.

The findings have been outlined in a study titled “Direct-ink-write cross-linkable bottlebrush block copolymers for on-the-fly control of structural color,” which has been published in the journal Proceedings of the National Academy of Sciences (PNAS).

Multi-color 3D printing with one material

While traditional colors come from chemical pigments or dyes that absorb light, structural colors found in some animals, such as Chameleons, are made from nano-textured surfaces that interfere with visible light.

Drawing inspiration from this natural phenomenon, the researchers used a 3D printable ink made from photo-cross-linkable bottlebrush block copolymers (BBCP), which feature a unique brush-like structure.

During 3D printing, the researchers altered the strength of the UV-light radiation as it cured the BBCP material. This caused the ink’s polymers to crosslink in different ways, producing a range of tiny lamellar structures.

After being 3D printed, these structures can exhibit a wide spectrum of vibrant colors, ranging from blue to red. By specifically modifying the UV-light during extrusion, the team were able to successfully produce a set of desired colors.

According to the researchers, timing is key to achieving this effect. It is essential to match the cross-linking timescale with the assembly timescale. Correctly correlating these factors ensures the polymer arrangements form the required structure shapes, which create the desired color as the material is cured.

Research in multi-color 3D printing

This is not the first time researchers have looked to nature when developing multi-color 3D printing processes. Back in 2021, scientists from the Eindhoven University of Technology (TUE) presented a novel color-changing liquid crystal ink compatible with direct ink writing (DIW) 3D printing.

The development of this ink was inspired by iridescent materials found in nature that change color based on the angle from which they are viewed, such as butterfly wings and the exteriors of jewel beetles. The ink’s reflective qualities are dependent on the precise helical alignment of the material’s molecules, which can be controlled during 3D printing by varying parameters such as 3D print speed.

The Eindhoven-based researchers view their multi-color 3D printing material as offering potential for applications such as decorative lighting, soft wearable sensors for health monitoring, and augmented reality optics.

Elsewhere, scientists from the Pacific Northwest National Laboratory (PNNL) developed a range of vibrant, colorful and sustainable seaweed-based bioinks for 3D printing.

Called ArtSea Ink, the biodegradable 3D printing materials are made largely from alginate, a naturally occurring polymer typically found in brown seaweed. Alginate is biocompatible, cheap, and can be used to form a stable gel without heat, enabling it to be 3D printed at low temperatures.

The researchers designed this material portfolio with artistic applications in mind, formulating eight 8% alginate solutions in water with different colored mica pigments. To test their material, the team 3D printed a glow-in-the-dark firefly and a bright blue anatomical model of a human brain.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows the multi-colored 3D printed chameleon. Image via University of Illinois Urbana-Champaign.