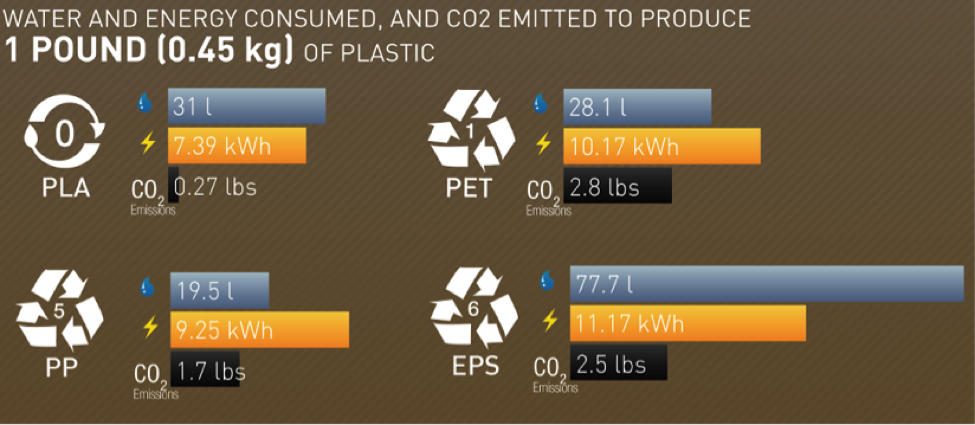

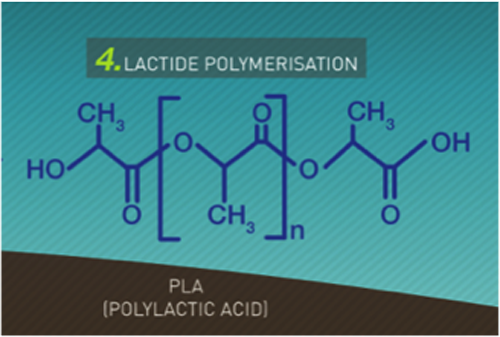

Polylactic acid or PLA has brought 3D printing closer to full green sustainability in recent years. When used as a filament in 3D printing, PLA eliminates most of the issues brought about by common petro-based plastics, resulting in less waste, non-toxic products, and reduced negative effect on the environment. PLA has become an increasingly popular choice for 3D printing material. Let’s have a look at the process from Plant to PLA filament, as illustrated by SelfEco, a manufacturer of eco-friendly materials.

PLA is the same type of plastic used in making environmentally friendly disposable cups and utensils labeled “compostable” or “made from corn.” It is produced from renewable crops such as corn, sugarcane, or tapioca, and is being widely used today as a safe, non-toxic, biodegradable, and eco-conscious material in medical implants, packaging, hygiene products, upholstery, injection molding, and more.

From Humble Plant to 3D Work of Art

PLA is quickly becoming the material of choice in the 3D printing community—projected to overtake ABS in the next few years—in part because of its low toxicity and environmentally friendly properties. But to become a green technology, PLA first needs to be created from plants. Here’s a quick guide to the PLA production process (Infographics courtesy of Selfeco/Green Design, MIT – Institute of Design):

- USA and Canada – corn (starch)

- Asia – tapioca (roots, chips, or starch)

- Rest of the world – sugarcane, wheat, or potatoes

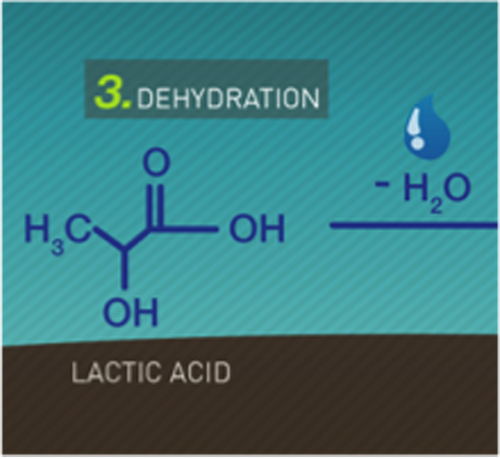

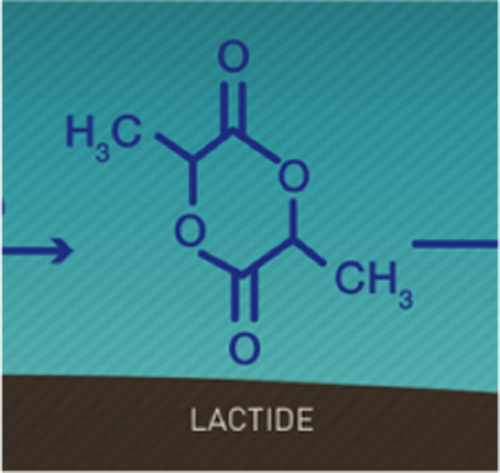

n purification via the removal of excess water in a vacuum or through azeotropic distillation, the two molecules of lactic acid form a compound called lactide.

PLA is slated to become even more affordable and greener as new production techniques using zeolite as a catalyst have been developed to eliminate the metals used and waste generated in current PLA processing, resulting in higher yields of lactide. The technology has been patented and is ready to be ramped up for use on an industrial scale.