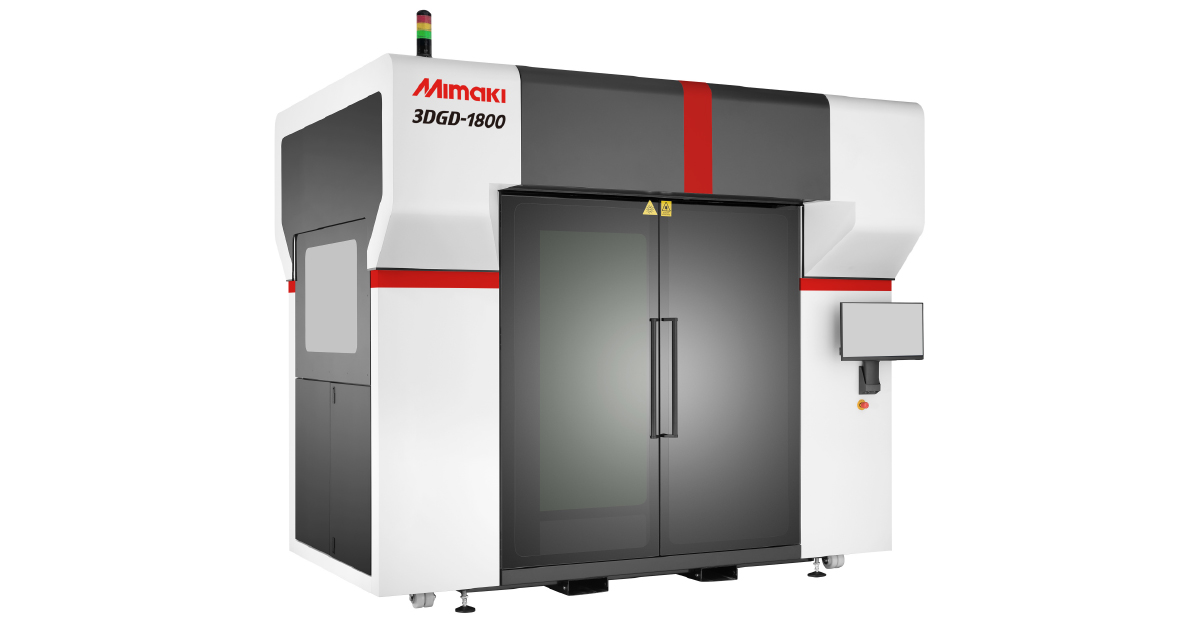

Mimaki Europe, a manufacturer of wide-format inkjet printers and cutters, has launched the Mimaki 3DGD-1800 3D printer, a new large scale system that uses Gel Dispensing Printing technology.

Mimaki has designed its 3DGD-1800 3D printer as a solution for sign and display applications across a number of diverse sectors. After objects are 3D printed, the company’s inkjet printers can be used to add further design choices in the form of colour and decorations. Commercially available from April 1 2020, the system has also been built with a focus on size and speed, reportedly capable of producing objects up to 1.8 metres tall in seven hours.

“Part of what makes our approach unique here at Mimaki is our dedication to being a Total Solutions Provider, and as such we have ensured that even beyond the 3D printing stage, our Mimaki inkjet printers can then be utilised to add colour and décor, making created objects even more impressive and immensely versatile,” comments Bert Benckhuysen, Senior Product Manager at Mimaki Europe.

“With our unique vision, wealth of experience from across the print industry and unwavering commitment to innovation, we intend to lead the sign graphics industry in both two- and three-dimensional signages – and the introduction of the new Mimaki 3DGD-1800 is a fantastic step forward in achieving this goal.”

3D printing at Mimaki

Founded in Japan in 1975, Mimaki Engineering develops, manufactures and distributes wide-format inkjet printers, cutting plotters and software. The company operates large manufacturing bases in Asia and the Pacific, the United States and Europe. Mimaki Europe was established in 2004 as the company’s gateway to EMEA regions. The subsidiary is responsible for sales, marketing, logistics, administration, a large force of service technicians and a distributor and reseller network.

Mimaki’s first full-color 3D printer was initially announced in 2015, after the company had launched its UJF-7151 plus model, which is capable of directly printing onto materials such as plastics, metal, wood, leather, and glass. As such, the UJF-7151’s UV cure/inkjet printing technology has been leveraged by the company as a base for 3D material jetting.

Mimaki then launched its 3DUJ-553 3D printer in 2018, which utilizes a proprietary 3D printing method combining a traditional inkjet print head with an economical UV-LED lightsource. This involves successively ink-jetted and cured layers stacking to form a full-color 3D object. The max build volume in the 3DUJ-553 is 500 x 500 x 300 mm.

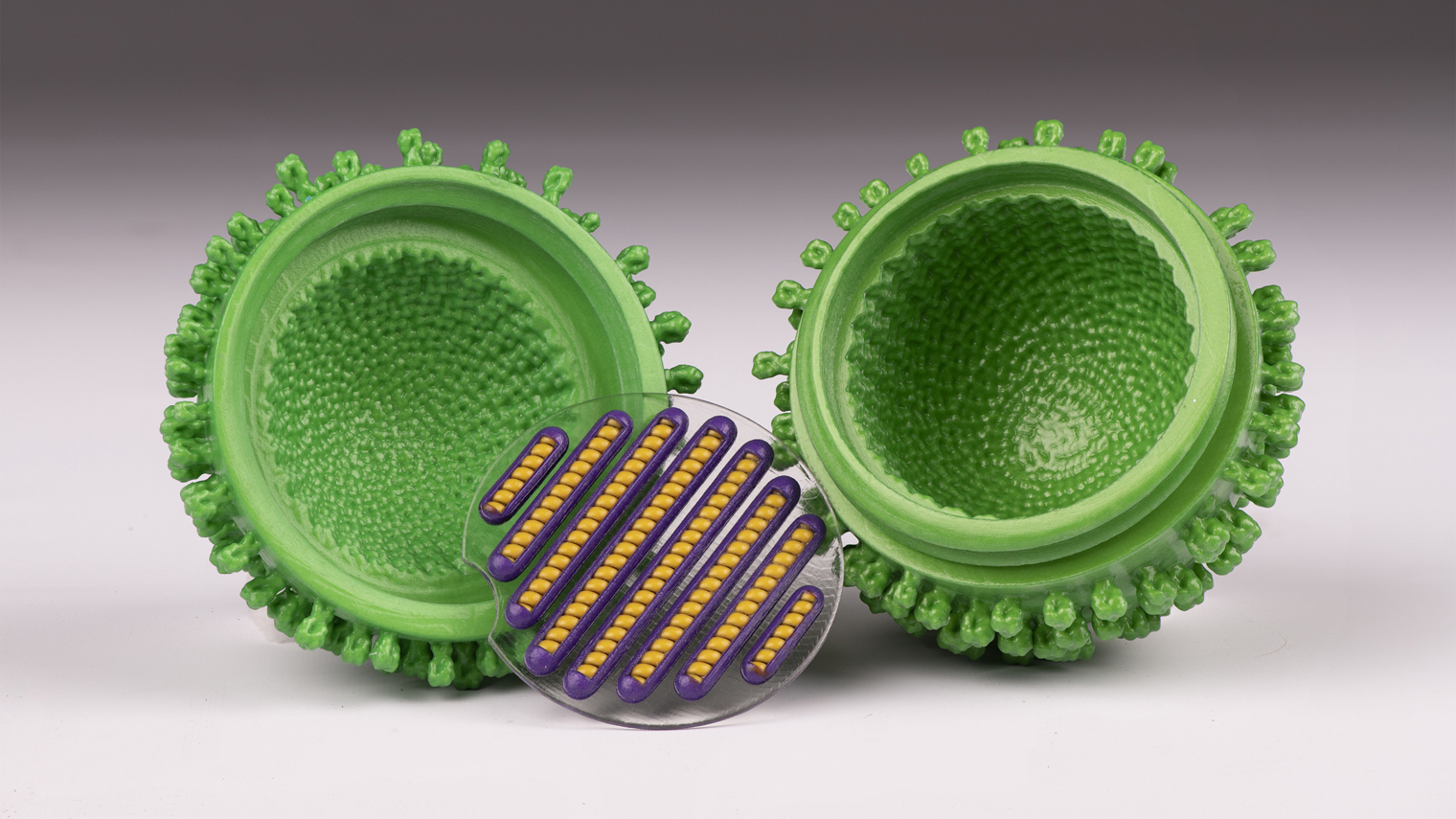

The full colour capabilities of the 3DUJ-553 3D printer has been used in a number of creative applications. For example, 3D body scanning technology company Twindom used the system to create a scale miniature community with models 1 to 2 inches tall. The 3DUJ-553 system has also been used to 3D print a detailed model of a sustainable town built in Minecraft as part of a nationwide competition in France.

Good signs for the new 3DGD-1800 system

Mimaki’s new 3DGD-1800 3D printer comes equipped with a number of features designed to cut down on costs and time. It uses a dual-head configuration allowing for the simultaneous printing of two structures; it also facilitates the production of support-free hollowed structures. This helps to streamline production while also enabling the addition of interior illuminations, increasing the system’s application possibilities across signs and displays, events, creative arts and interior design.

The new 3D printer uses Gel Dispensing Printing technology, which extrudes a gel-type UV curable resin, which is then cured instantly using a LED UV light, thus enabling lamination speeds of up to 350mm in height per hour, according to Mimaki.

Mimaki expects the 3DGD-1800 3D printer to provide a number of opportunities to sign makers in a range of industries. For example it potentially allows users to create detailed life-sized displays, event decorations, movie props, large product mock-ups and more. At the other end of the scale, it can also be used to manufacture production parts such as moulds for vacuum forming.

“We are very excited to be able to bring such a transformative product to market,” continues Benckhuysen. “With unprecedented modelling speeds and the possibility to create enormous objects even beyond the sizeable formation area, the 3DGD-1800 represents a real transformation in large-sized production. Combined with the superior quality that we have become known for here at Mimaki, the potential impact of this new 3D printer is tremendous – particularly for the sign and display market but also far beyond that. The opportunities are boundless.”

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Mimaki 3DGD-1800 3D printer. Photo via Mimaki.