How do you honor a hip hop legend using 3D printing? Why 3D print vases made from human tissue? How is an accountancy firm using 3D printed prosthesis? And, finally, how is 3D printing launching satellites into space?

Today in Sliced, our 3D Printing Industry news digest, we answer the following questions:

Read on for a collection of all the latest news regarding material innovations, business partnerships and medical research in the industry, with updates from Prusa, Carbon, EnvisionTEC and more.

3D printing provides detailed dioramas in colour

The artistic potential of 3D printing is quite literally endless, as shown in this roundup of recent creative applications.

This week American radio presenter and hip hop personality ‘Charlamagne tha God’ gifted ATL and Entourage actor Lauren London a pendant honoring her late boyfriend and West Coast legend Nipsey Hussle. Designed by renowned jeweler Greg Yuna, the pendant applies 3D printing to create a strikingly detailed portrait of the artist who was fatally shot earlier this year.

Talking to HYPEBEAST, Yuna explains the process behind creating Charlamagne’s gift for London: “We [had to] make a CAD [file] and spend tedious endless hours on the computer trying to get as much detail as possible in so we can print it on a state of the art 3D printing machine. Finally, we cast it in gold and laser in the tattoos and do the finishing touches including the hand-selected full cut diamond in his ear.”

3D printing has also been applied to the creation of Delftware vases by Biomedical Engineering professor Dr. Patricia Dankers and her PhD candidate, Dan Jing Wu, at the Eindhoven University of Technology (TUE).

Delftware traditionally consists of blue and white pottery, with designs originating from as far back as 1600. Its name comes from the city of Delft in the Netherlands, which was a major center of production for the earthenware.

A key difference of TUE’s 3D printed Delftware however, is that it is made using human tissue. Each vase in this unusual collection are 3D printed with a biodegradable polymer, which then creates a scaffold enabling the growth of human tissue, making up the surface of the vases. They were created for an exhibit at Paris’ Centre Pompidou earlier this year to explore the design potentials of human tissue engineering.

Elsewhere, 3D body scanning technology company Twindom has reported an interesting use case for its full-color resin 3D portrait service using the 3DUJ-553 full-color 3D printer from Mimaki. The machine was used to create a scale miniature community with models 1 to 2 inches tall, as shown below. Impressed by the quality of the prints Will Drevno, founder of Twindom, commented:

“It’s crazy to see the level of detail full-color 3D printers have reached even for very small 3D prints.”

Hot Lithography proves too hot at the Research Oscars

Materials in the 3D printing industry are constantly advancing toward an improved quality for finished parts. Several companies this week have made significant efforts towards developing 3D printing material technologies.

German chemical manufacturing enterprise Henkel has launched an open materials platform to facilitate the collaboration with various 3D printer manufacturers and system providers, with the end goal of qualifying new materials for different 3D printing technologies. A core element of the platform centers on several newly developed materials by the company, consisting of the UV-curable Silicone Elastomeric, Ultra Clear, Durable High Impact, High Temperature and General-Purpose resins under the Henkel Loctite brand. Henkel will showcase recent additions to its open materials platform during the upcoming RAPID + TCT Conference in Detroit, from May 21-23 at booth 609.

“With our new materials platform we offer innovative building blocks to engineers and designers to realize their ambitions,” explained Sean Dsilva, Head of 3D Printing Materials at Henkel.

“Manufacturers of 3D Printers and system providers that work with us benefit from our unique offering of next generation resins, which provides solutions to some of the most severe limitations in the 3D printing market. This is the next step to move additive manufacturing from prototyping to functional part productions across markets.”

3D printing has been walking down a different type of red carpet this week with Cubicure, a Vienna-based startup specializing in the additive manufacturing of high performance polymers, thanks to its ‘Hot Lithography’ material processing. The company placed 2nd in the ‘Research & Development in SMEs’ category at the ‘Houskapreis‘ 2019 research funding award in Austria, and was presented with a ‘Research-Oscar’ for the Hot Lithography technology. Working with viscous resins, Cubicure’s Hot Lithography process makes high definition plastic objects that exceed the properties of many common light-reactive materials.

3D printing resin supplier Adaptive3D has entered a partnership with global chemical company Chemence to support its accelerated growth schedule in additive manufacturing and specialty materials. Under the partnership agreement, Chemence will use its ISO 9001 certifications to help Adaptive3D manufacture and package its current portfolio of premium additive manufacturing photopolymer resins.

“Working with Chemence and leveraging their history of manufacturing excellence in adhesives and acrylates is a very compelling proposition for Adaptive3D,” remarked Stephen Kay, Head of Operations at Adaptive3D. “We believe that their 30 years of experience, global manufacturing footprint, and ISO 9001 certifications give our customers the security they need to depend on our products for additively manufacturing functional end parts and products as well as functional prototypes.”

WACKER, a Munich-based chemical group, is launching a Chinese website and webshop for its ACEO silicone rubber 3D printing brand. The website will provide information, infographics and videos explaining ACEO‘s drop-on-demand printing process. Recently, Wacker opened its first ACEO Open Print Lab in the U.S., and with its new Chinese webshop, the company is continuing to expand the ACEO brand globally.

Name change for Prusa Research software

This week sees a couple of updates rolled out for key pieces of 3D software.

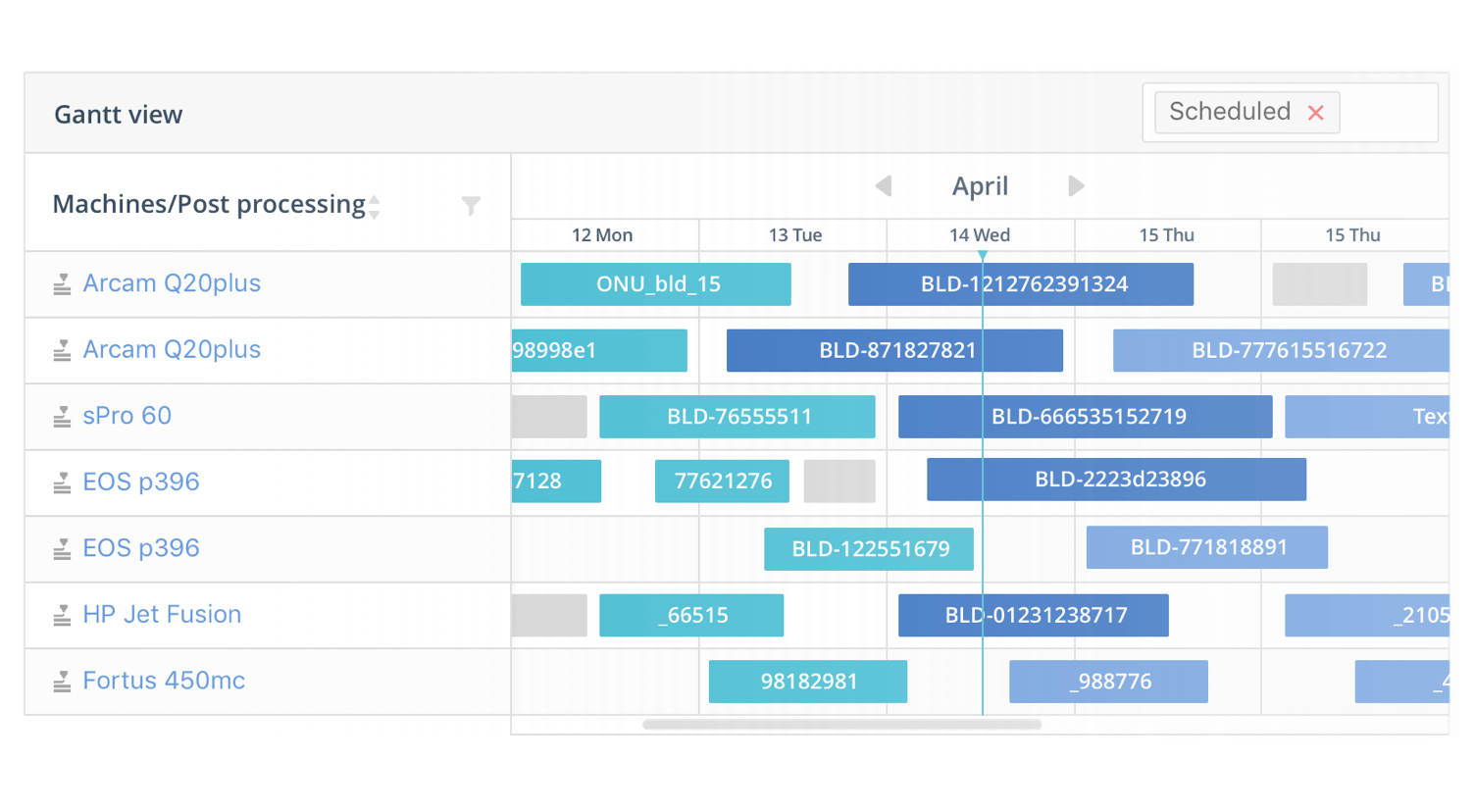

AMFG, a London-based provider of automation workflow for 3D printing, has announced an upgrade to its AI software. The platform now features customizable add-ons that automate the request and ordering processes for OEM’s and service bureaus, with the aim of reducing the time spent handling internal requests for 3D-printed parts and increasing workflow efficiency.

Felix Doerr, AMFG’s Head of R&D and Partnerships, stated, “The ability to standardise the process of receiving incoming requests or orders for parts is the first step to establishing an agile and scalable additive manufacturing process.”

“Our Request and Ordering Portal gives businesses the flexibility to eliminate the intrinsically manual nature of this process through automation.”

Award winning open source 3D printer manufacturer Prusa Research has updated the name of its edition of the open source 3D slicing Slic3r software. Previously titled Slic3r Prusa Edition, the new name is now PrusaSlicer.

3D printing partnerships in maritime, architecture, and space

Various partnerships, from distribution deals to research agreements and more, have taken place in the 3D printing industry recently.

Dynamical 3D, a Spanish reseller of 3D printers, has signed a partnership with the Silicon-Valley based Carbon, adding the company to its reseller network. Dynamical 3D will now be able to provide Carbon’s CLIP enabled DLS technology to its clients within Spain.

Further distribution deals have taken place, this time between Italian 3D printer manufacturer DWS, and Europac 3D, a 3D printing bureau based in Cheshire. Europac 3D will act as DWS’ exclusive distributor for the UK. John Beckett, Managing Director of Europac3D, comments; “We are delighted to have been selected as their exclusive distributor here in the UK, the unique technology of DWS gives us the opportunity to explore new verticals and applications within the rapid manufacturing market and strengthens our portfolio immensely.”

Dimensional Innovations (DI), a Kansas-based architectural company, has acquired a Large Scale Additive Manufacturing (LSAM) 3D printer from Thermwood Corporation, a developer of LSAM technology. Featuring a build volume of 10 x 20 x 5 ft and costing DI $2.2 million, it was was acquired to be used on a secret project that the company isn’t allowed to discuss at this time.

CEO Tucker Trotter of Dimensional Innovations said, “Within the design, architecture and construction space, we’re not aware of anyone else who has this capability […] There is not really someone else we can look to for examples on how to use this equipment, so we’re going to have to define that. It puts pressure on our team because there aren’t answers yet, but it also opens up incredible opportunities.”

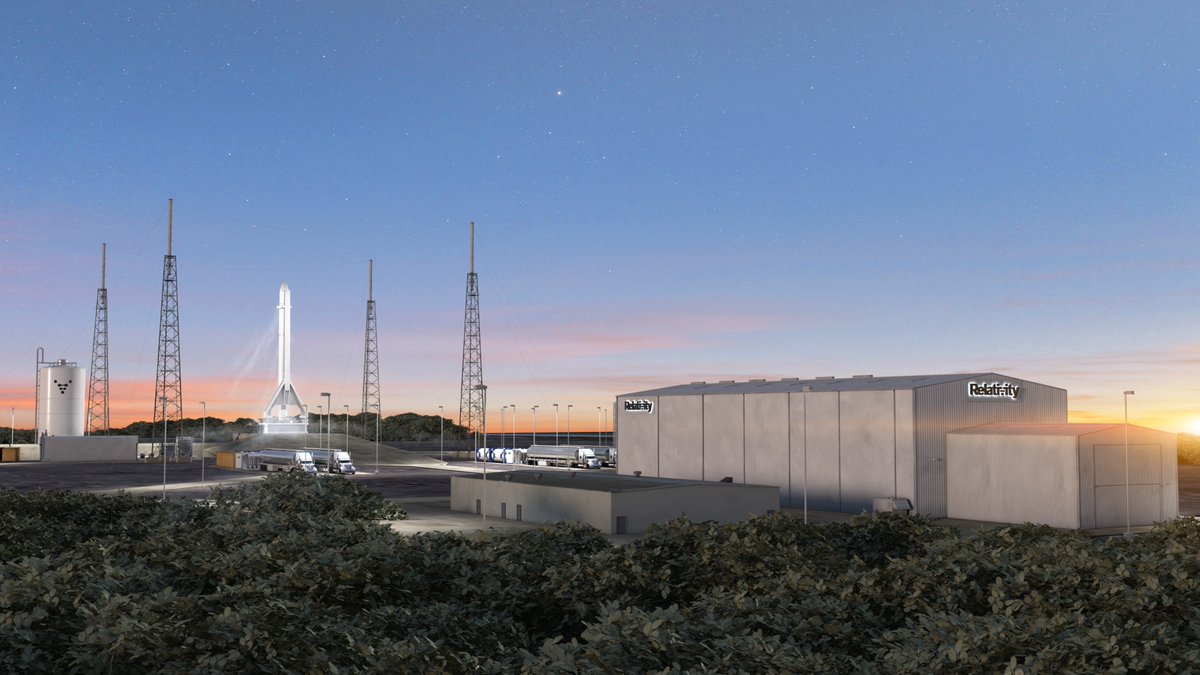

Relativity Space, a California-based aerospace company, has signed a a new Launch Services Agreement (LSA) with satellite rideshare and mission management provider Spaceflight for its 3D printed Terran 1 launcher. Relativity will use the LSA to establish itself as a launch option for the small satellite, microsat, and cubesat launch market. The 3D printed Terran 1 launcher will be utilized to send small satellites into Medium Earth Orbit (MEO) and Geostationary Transfer Orbit (GTO) missions. This follows recent news from the company where it signed a contract with Telesat, a Canadian communication satellite maker, to use the 3D printed Terran 1 spacecraft to send small Telesat satellites into the Lower earth orbit (LEO).

Oslo-based international classification society DNV GL has signed a four-year research collaboration agreement with Nanyang Technological University (NTU) in Singapore to support academic advances in additive manufacturing for the maritime, oil and gas and other industries. The research agreement will focus on developing additive manufacturing industry standards, quality assurance processes, certification and supply chain tracking. DNV GL had previously been appointed as the lead researcher of the Maritime and Port Authority of Singapore-initiated Joint Industry Program (JIP) which seeks to accelerate additive manufacturing in the maritime industry.

“This research collaboration demonstrates DNV GL’s commitment to R&D in 3D printing, and securing the safe deployment of the technique in maritime and oil and gas, at a time when the technology is undergoing rapid advances and as growth in its use is expected to grow exponentially,” explained Brice Le Gallo, Regional Manager South East Asia and Australia at DNV GL.

Developing 3D printed prosthetics in India

Finally, we proceed to the medical and dental sectors, where recently the Canadian government issued new guidance for the 3D printing of medical devices. As well as this, various initiatives have been established across the globe to help develop the implementation of 3D printing into medical and dental practices.

EnvisionTEC, a global 3D printer and materials manufacturer, and uLab Systems, a digital dental company based in California CA, have announced a partnership to simplify the uLab 3D dental aligner software. Having already validated EnvisionTEC’s Vida and Micro XL 3D printers for use with its software, uLab has worked with the company to include a one-touch button functionality for its dental planning software on the Envision One, allowing a smooth transition from software directly to hardware.

“We were attracted to the speed and ease of use of the Envision One,” commented Charlie Wen, Chief Technological Officer and President of uLab Systems.

“It will allow our customers the ability to easily transfer their cases directly to a powerful 3D printing solution capable of printing 6 horseshoe arches for clear aligners in 15 minutes. Providing the highest quality patient care is now faster and more streamlined.”

3D Prototyperz, a 3D printer manufacturer based in India, has worked with Mobility India, an organization dedicated to disability, development and rehabilitation, to research and carry out the 3D printing of prosthetic devices for below knee amputees. After having completed the initial pilot phase of the program, the researchers are now ready to move on to the next stage of development, where they are hoping to validate the technology and bring further awareness to the benefits of 3D printing prosthetic devices in India.

Big four accounting organization Deloitte will be providing 3D printed limbs to its employees within its offices who need them, as part of an initiative from the company’s North West office. Titled the CSR project, it initially began when Deloitte director Claire Handby worked with the Deloitte Digital team to 3D print a functioning digital hand for her niece, Phoebe Dyer, who was born with Dysmelia resulting in her having no left hand. After proving successful, Deloitte decided to provide 3D printed limbs to help people across the firm’s offices in London, Reading and South Africa.

You can now cast your vote for the third annual 3D Printing Industry Awards. Help decide this year’s winners now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Sliced logo on image of Hongjie Yang’s Delft blue vases 3D printed with a biodegradable polymer. Image via Studio Hongjie Yang/TUE