Mimaki USA, a manufacturer of wide-format inkjet printers and cutters, and the Smithsonian are collaborating to use additive manufacturing within its museums and research centers exhibitions.

The Smithsonian Exhibits’ (SIE) studios, in Landover, Maryland, has installed a Mimaki 3DUJ-553 full-color 3D printer to support the development of engaging exhibits, as well as produce 3D printed models for public programs.

“This printer will enable the Smithsonian to use new technologies to produce exhibits in new ways, particularly for creating models and tactile elements that help bring exhibits to life for all visitors,” said Josh Hope, Sr. Manager, 3D Printing & Engineering Projects at Mimaki USA.

3D printing at the Smithsonian

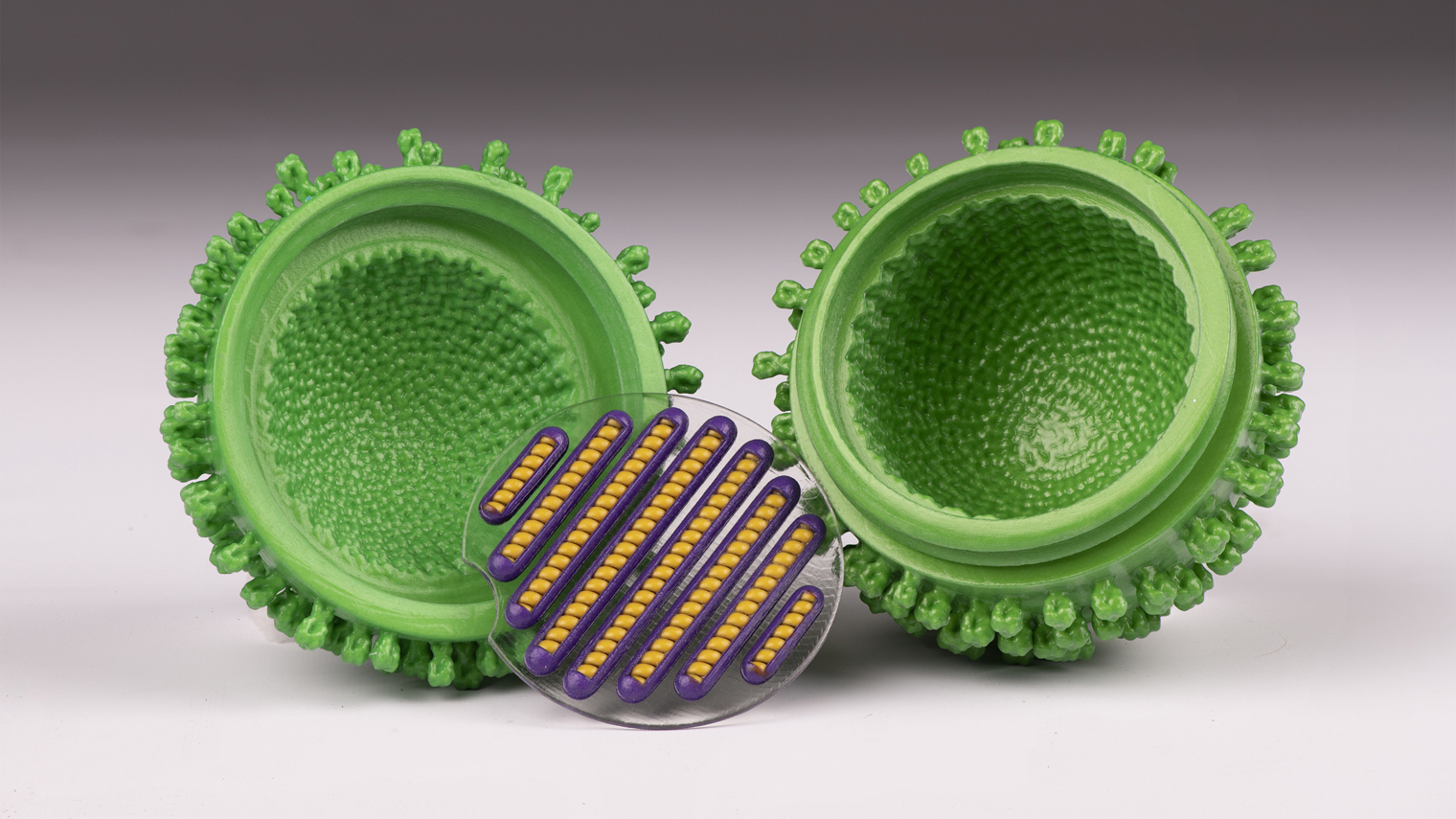

A team at SIE is currently integrating 3D printing in the Outbreak: Epidemics in a Connected World exhibition which is on view at the National Museum of Natural History in Washington, D.C., one of 19 Smithsonian’s institutions. They aim to create 3D printed influenza virus models with a specific texture for audience engagement.

This 4250-square-foot exhibition invites visitors to identify and respond to infectious diseases, such as HIV/AIDS, Ebola virus, influenza, Zika virus, as epidemiologists, veterinarians, public health workers, and citizens would. In due time, the SIE team believe that additive manufacturing will be used for a collection of hands-on models for educational activities as well as tactile display elements for low-vision or blind visitors.

“We are pleased to be a part of the Smithsonian Institution’s efforts to engage and inspire audiences through the increase and diffusion of knowledge,” added Hope.

Full-color 3D printing

Mimaki’s first full-color 3D printer was initially announced in 2015 after the launch of the company’s UJF-7151 plus model capable of directly printing onto plastics, metal, wood, leather, and glass. Therefore, the UJF-7151’s UV cure/inkjet printing technology has been used as a base for 3D material jetting.

The 3DUJ-553 utilizes a proprietary 3D printing method combining a traditional inkjet print head with an economical UV-LED lightsource. This involves successively ink-jetted and cured layers being build-up to form a full-color 3D object. The max build envelope in the 3DUJ-553 is 500 x 500 x 300 mm, a size competitive with many other systems on the market.

3D body scanning technology company Twindom recently reported an interesting use case for its full-color resin 3D portrait service using the 3DUJ-553 full-color 3D printer. The machine was used to create a scale miniature community with models 1 to 2 inches tall, as shown below.

For more 3D printing news, subscribe to our 3D printing newsletter. You can also join us on Facebook and Twitter to see live updates. We also have opportunities additive manufacturing, visit our 3D Printing Jobs site to learn more.

Featured image shows a 3D printed influenza virus model in an opened position. The clear disk that contains the eight purple capsids and the eight yellow RNA strands has been removed from the green envelope. Photo via Mimaki USA.