Not Impossible’s project to bring low-cost 3D printed prosthetic hands to Sudan, starting from one young man named Daniel who had lost both arms in an explosion, moved the world when it was made public last January. Now Mick Ebeling, Not Impossible’s co-founder, was asked to go over what was accomplished in one of the world’s poorest and most war-ravaged areas, for Land Rover’s Can and Will campaign.

The campaign focuses on the stories of extraordinary individuals that overcame the odds through defiance and determination, which the UK’s car manufacturer wants to support with its own “go-anywhere” brand philosophy, which fits just right with the concept of fully delocalized manufacturing possible through 3D printing.

Ebeling was thus asked to give a 5 x15 talk (a format where 5 speakers each have 15 minutes) to tell the audience about that feat and what it has meant for a local community where, due to a long and devastating war, thousands are amputees.

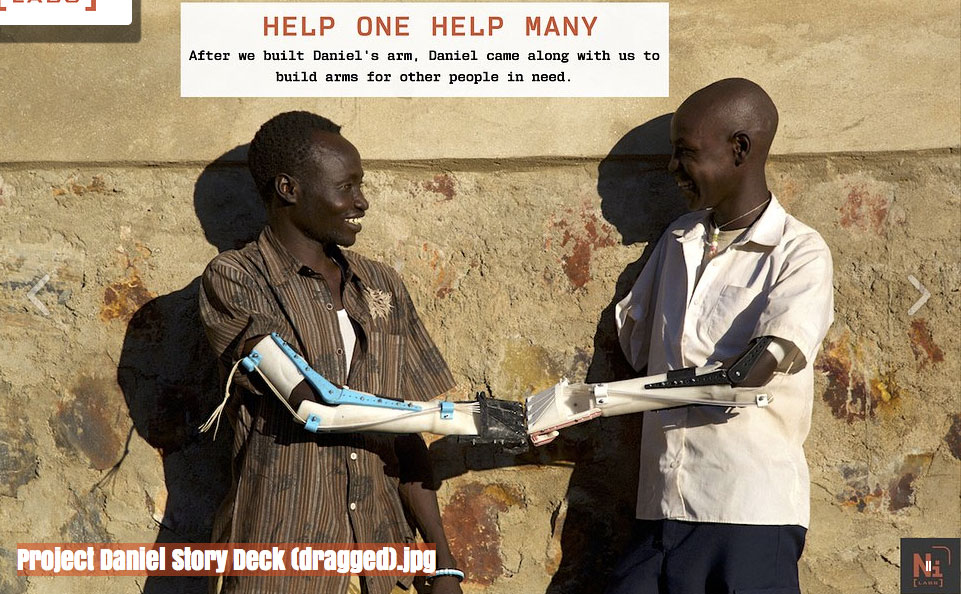

Moved to act by Daniel’s words after having lost his upper limbs, Ebeling allowed his own “If not now, then when? If not me, then who?” way of life and went to Sudan to set up a delocalized prosthetic hand factory, using just a few computers and MakerBot’s desktop 3D printers, in a 70,000 person refugee camp.

Before heading to Sudan, Ebeling had met with Richard van As, founder of Robohand, who taught him how to print and assemble a prosthetic hand, while also showing him the ins and outs of running a 3D printer in extreme conditions. Project Daniel was a success, as is Robohand and as is the e-NABLE project: all of them show how 3D printers can really “go anywhere”, to give our world a hand.