Sigma Labs of Santa Fe, New Mexico have announced a new contract with Honeywell Aerospace. The project extends work with the Defense Advanced Research Project Agency (DARPA) as part of the Open Manufacturing (OM) program. Sigma Labs were founded in 2005 by scientists from the renowned Los Alamos National Lab.

Valued at $400k, the contract will see Sigma Labs continue to work on their PrintRite3D® technology. Mark Cola, President and CEO of Sigma Labs explains,

PrintRite3D® technology enables rapid manufacturing processes such as laser-based 3D printing for precision metal components. Through this award, we’ll have the opportunity to demonstrate how our PrintRite3D® software can be a key enabler for developing quality assurance standards for metal AM aerospace components.

The news marks the third phase of the contract between Honeywell and Sigma Labs and aims to make 3D printing with metal a more widely used technology. When I spoke with the director of DARPA’s Open Manufacturing program earlier this year, he explained to me how the agency has been looking at 3D printing since the late 1990s. At the Pentagon innovation agency there are two strands related to additive manufacturing, the Rapid Low Cost Additive Manufacturing (RLCAM) effort and the Titanium Fabrication (tiFAB) effort.

Increasing adoption of metal 3D printing

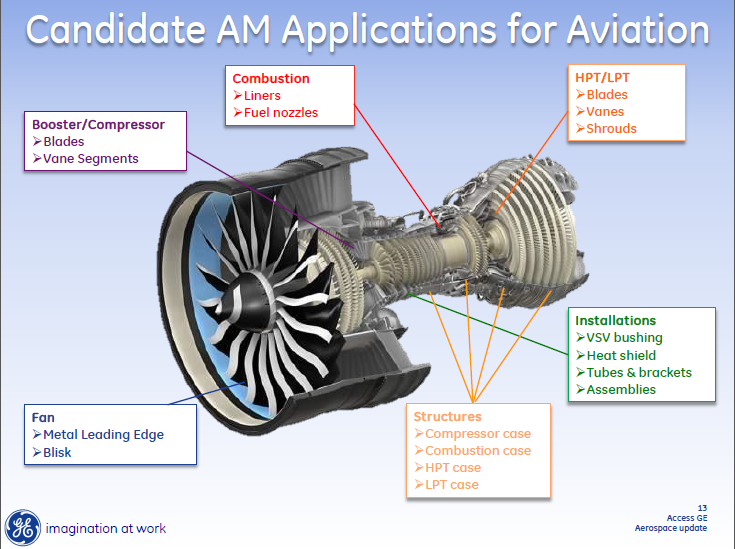

DARPA’s OM program is focused on lowering the barriers to adoption of metal 3D printing by improving speed, cost and repeatability. While multinational enterprises such as GE are using 3D printing to manufacture components for aerospace applications, metal additive manufacturing for production is still at an early stage.

DARPA OM program director Mick Maher explains how the work is progressing,

We have got a framework together using physics based models. A network of physics based models that model everything from the powder bed to the melt pool, to the laser. We’ve run a series of experiments to calibrate those models so that we understand how these parameters affect the properties and microstructures that are developed within the metal and include some of the environment conditions or starting conditions like the powder size or powder chemistries.

Critical work and breakthroughs in understanding

Sigma Labs with their quality assurance software will play a role in increasing understanding and controlling build chamber metrology. The high temperatures reached inside a metal powder bed 3D printer present particular challenges to manufacturers and are also the focus of scientists working at national laboratories such NIST and Lawrence Livermore. The work has resulted in several breakthroughs in how to produce 3D printed metal parts faster, but also make them stronger.

The ability to predict, monitor and control such metrology is critical to increasing the adoption of 3D printing with metal, Sigma Labs are not the only enterprise working in this area but with the continued support of DARPA and Honeywell we will be closely watching their progress.

Do you think DARPA’s work deserves an award for advancing 3D printing, or is Sigma Labs one the most innovative additive manufacturing enterprises? Let us know and make your nomination in the 3D Printing Industry Awards.