Whilst Apple’s iDevices are designed to require a relatively low requirement of vital ‘hidden-cost’ add-on peripherals — in part because of the vast amount of non-vital paraphernalia that Apple propagated as a culture of personalisation to express individualism in a milieu of iPhone ubiquity — they are designed to require an external speaker. The lack of maxed audio has been irritating Max Freeman of Geomagic Solutions for a while…

With about an hour free between meetings Max was surrounded by 3D printers at the 3D Systems Geomagic office in North Carolina and decided to challenge himself to design and print a solution in only that brief window.

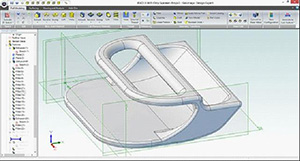

Design is 3D Systems’ Geomagic’s core CAD software. With an arsenal of measurements from Apple he fired out the first prototype of a small attachment that fits over the speaker area to redirect the sound forward. Whilst experience of course provided a huge boost to the process it took a mere 25 minutes to complete the design. Max then saved it as an .STL and ran it through the Cube software and went over to start a print.

The first design prototype was 3D printed in 45 minutes. Max then put the design to the test, he found that his design did indeed make the audio ‘much louder.’ However, the design meant it would slip off too easily from the iDevice of Max’s choice: his iPad. As per the usual prototyping process he moved on to prototype number two to resolve this design problem.

The next day Max had free time again, stage two CAD and prototype 3D print followed. Within about 20 minutes Max suggests that he found it pretty simple to add some curves and remove some unneeded material so it would “print faster and look sleeker.” 45 minutes later he had prototype two. He openly and humbly says that it fit well, looked better… but performed terribly at its job as a sound-bouncer! In his thirst to remove material, he had removed a key area that bounced the sound forward.

For prototype number three, Max replaced the material in the back of the design, tightened the dimensions a bit more and set it going in a Cube printer. 45 minutes later max had a device to max his iPad audio.

Whilst Max has experience with the design process and 3D printing, from initial concept to the final production process took a mere handful of hours. As a counter ‘hype’ statement I’m going to add that Max’s speed should not be interpreted as something that anyone and everyone may achieve with little effort. But, like word-processors, spreadsheets and particularly 2D photo-editing software, the rate at which beginners pick the software up will increase as the software gets more accessible. Why not give it a shot yourself at a local MakerFaire or Hacklab for free? The skills learned, end use 3D-printable and – dare I say it – fun, are all great reasons to get involved. What have you got to lose…?