For me, human tissue bioprinting is the most fascinating frontier in 3D printing, albeit the most complex and difficult one. The additive processes for this application are similar to any other 3D printing process but the materials they process and the structures that need to be assembled are so much more complex. A new material combination developed by researchers from ETH Zürich, AO Research Institute Davos in Switzerland and INNOVENT in Germany, however, holds great promise for one of the first feasible applications of bioprinted tissues: cartilage.

Cartilage is the first tissue candidate that scientists believe can effectively replicate end use in humans. That is because it is a single cell, stratified structure that adapts well to the many 3D bioprinting processes and thus is not as complex as organs and other tissues such as skin.

There are a few different ways to try to bioassemble cartilage; the most common is by developing a scaffold in a biocompatible material such as gelatin, alginate, carbohydrate glass, and thermoplastics such as polylactic acid (yes, PLA) and applying a bioink made of cartilage cells to it. In other words by creating a combination of materials that could resemble the properties of cartilage, at the same time strong and soft enough to provide “padding” for the smooth motion of joints.

The experiments conducted so far by many institutions throughout the world, although promising, have yielded bioinks that are too soft and weaken over time. Finding the right balance is made more difficult by the fact that the material also has to be 3D printable, that is, it needs to be soft enough while extruding at temperatures that are compatible with cellular life and, at the same time, it needs to solidify (or gellify) fast enough so that it can retain the shape digitally designed though the CAD file instructions.

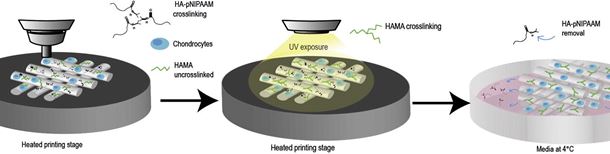

The scientists at ETH, AO and INNOVENT think they have found this ‘perfect’ combination by combining poly(N-isopropylacrylamide) – represented by the symbol pNIPAAM – and HA (hyaluronan) to create an ink that is liquid at room temperature but solidifies when printed onto a substrate heated to body temperature (37°). To make the scaffolds more durable, even under mechanical compression, a second polymer – hyaluronan methacrylate or chondroitin sulfate methacrylate (CSMA) – can be added, which covalently crosslinks within the HA-pNIPAAM gel to form a network.

The complex acronyms make this seem even more far out than it actually is. What the scientists did is simply turn their attention to the natural components of cartilage, such as chondroitin sulfate and HA. In their original form the precursor solution to these materials are too liquid and slow gelling to print with but by adding a heat-responsive biocompabile polymer they found they could create a promising bioink.

“The mix with HA-pNIPAAM opens up a whole range of polymers that can now be printed with good cell viability and good resolution,” says Zenobi-Wong of ETH Zurich. “HA-pNIPAAM can basically be combined with any crosslinkable hydrogel precursor… [and] serve as a basis for many other bioinks for different tissue engineering applications.”

This is just one more step toward bioprinitng of the simplest human tissue. There are so many things we need to find out about before successfully 3D printing organs that there are millions of possible approaches, all equally valid, and million of exciting discoveries to be made through experimenting.