Nick Walker sheds some light on the world of 3D printing and its applications within automotive restoration. Read on to find out more.

It seems like it wasn’t all that long ago that the concept of 3D printing had to be explained to me. Which makes it all that much more amazing that just a few years later I would be hard pressed to find someone who didn’t understand what it is.

3D printing has rather quickly risen to center stage as a fast and simple way to create the parts you might need. Everything from prosthetics for endangered animals to abstract art are now produced with 3D printers on a daily basis.

Still, there are plenty of creations being dreamed up that 3D printers simply can’t make.

Sure, a 3D printer is capable of printing a replacement 4th gear for a 1921 Bentley 3 Litre’s transmission, but what is that exact physical copy made out of? Even if it is 3D printed using the new Filamet™ copper or bronze filaments, it simply won’t have the same strength, wear, and heat resistance characteristics of a solid metal part.

Would a 3D printed automotive transmission gear be ideal for mockup purposes? Absolutely! But the unfortunate truth is that for the most part 3D printing has not advanced to the point that the specifications of that gear will be acceptable for use in real world applications.

Even if made with a much more advanced type of 3D printing process such as direct metal laser sintering, the cost would be astronomical and multiples would have to be made so that the part’s strength could be extensively tested before installation.

Which means that there are countless situations where 3D printing just doesn’t cut it. And that’s pretty much anywhere requiring parts with high heat resistance and strength.

So what’s a person to do if they need a replacement part that meets the original specifications? Or if a custom high strength, heat resistant part is needed to improve on a particular design?

Of course, the answer is that the part would need to be machined from a material that can adequately withstand the forces applied to it.

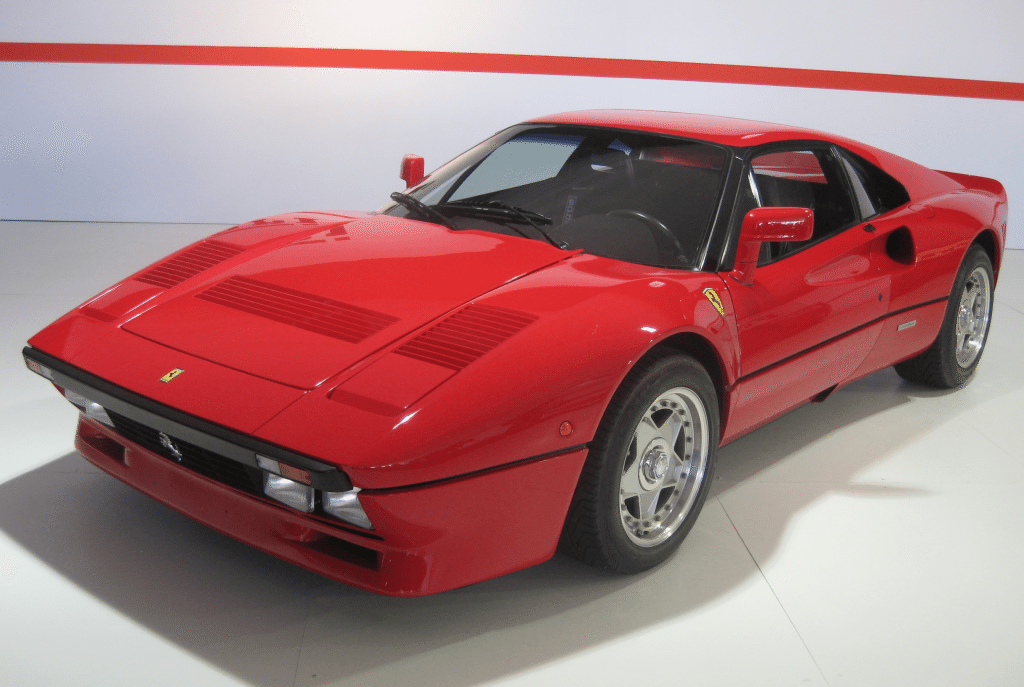

This is precisely the realization Eric Halpert (not his real name) had when working out how to create his modern interpretation of a Ferrari 288 GTO. Unlike those who set out to build a replica car from an uninspiring Volkswagen Beetle, Toyota MR2, or Pontiac Fiero, that was not Eric’s intent. Instead, the plan was to take what many would have considered to be a perfectly good 1987 Ferrari 328 GTS and “RestoMod” it into the Ferrari 288 GTO he had dreamed about for the last 25+ years. Although not an inexpensive endeavor by any means, with the current value of a quality Ferrari 288 GTO ranging from between $2,000,000.00 and $3,000,000.00, the RestoMod option was a bit more obtainable.

To accomplish his goal, some really interesting engineering challenges needed to be addressed. There were many, but perhaps one of the most significant was that in order lower the car’s center of gravity and convert to a dry sump, the 328 GTS’s engine orientation had to be changed from transverse to longitudinal. And in making this change, the 328 GTS’s transmission needed to be removed and replaced with one that could accept a longitudinally mounted high performance engine.

If you don’t have a background in automotive mechanics, you might not realize how serious of an undertaking such a project is. If you do have a background in automotive mechanics, you might say that finding a way to come up with $2,000,000.00 to $3,000,000.00 to buy an original Ferrari 288 GTO is probably an easier goal to accomplish!

After doing a bit of research, Eric settled on a transmission pulled from a Ferrari 360 Modena. In theory, a transmission from any manufacturer could be used so long as it had the proper gear ratios and could handle the power that would be put through it, but there was a strong desire to keep the car a Ferrari through and through.

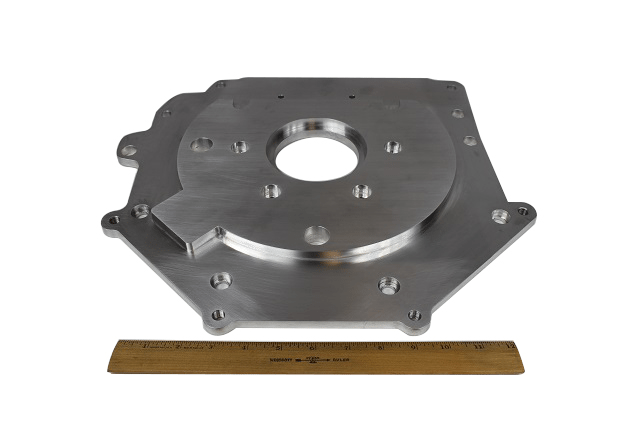

Although both the engine and transmission were manufactured by Ferrari, no one had ever tried to mate this particular combination together. And there’s a reason that this is not something that is commonly done. As you can imagine, a Ferrari 360 Modena transmission doesn’t just mount perfectly to a Ferrari 328 GTS engine. So in order to mate these two pieces, a custom made, high strength, heat resistant adapter plate would need to be designed and created.

Although the adapter plate could have been 3D printed in plastic for mockup purposes, Eric was confident in the part’s design. And even though theoretically this particular part could be made using direct metal laser sintering, the cost to manufacture the adapter plate using this method would not only be prohibitively expensive, but would also likely come with some unknowns in regards to specifications.

So what did Eric do to solve his problem? Like any good engineer, he found a way to make it work without reinventing the wheel.

Eric knew that in order to meet or exceed the required specifications that the only real option he had would be to have a solid aluminum adapter plate custom made by a reputable machine shop. A quick Google search and some research led him to eMachineShop, a reputable NJ-based machine shop who’s been making custom parts since 2003. Although eMachineShop offers free parametric CAD software to design and price parts, Eric had already asked his engine builder to take the necessary measurements and create the schematic for the transmission adapter plate as well as for an air intake adapter plate he would need using another CAD program. So he just submitted the files to eMachineShop for quotation.

Eric received the quotes, reviewed them, and placed his orders. eMachineShop got to work milling the parts and shortly after the two adapter plates were delivered to his door.

It’s always a bit exciting to get a package delivered, but one can only imagine what it might feel like when that package allows you to mate a Ferrari 360 Modena transmission to a Ferrari 328 GTS engine and top it off with a horsepower-boosting cold air intake.

For those of you wondering if Eric is using any 3D printed parts on his chimera prancing horse, the answer is, “There’s still time if the price and quality meet the required specifications.” Although the FrankenFerrari project is still in the works, the car is bit by bit moving towards completion. So keep your eyes open for what looks like a Ferrari 288 GTO. If you’re lucky, you’ll be able to hear the throaty roar of a modified Ferrari 328 GTS engine over the whine of the servomotors in your 3D printer.