Scientists at Lawrence Livermore National Laboratory (LLNL), SLAC National Accelerator Laboratory (SLAC) and Ames Laboratory are researching X-ray imaging to examine metal parts during the laser powder bed fusion process. The research paper is part of a partnership between the laboratories to identify the causes of defects in metal 3D printed parts and understand how those flaws can be mitigated.

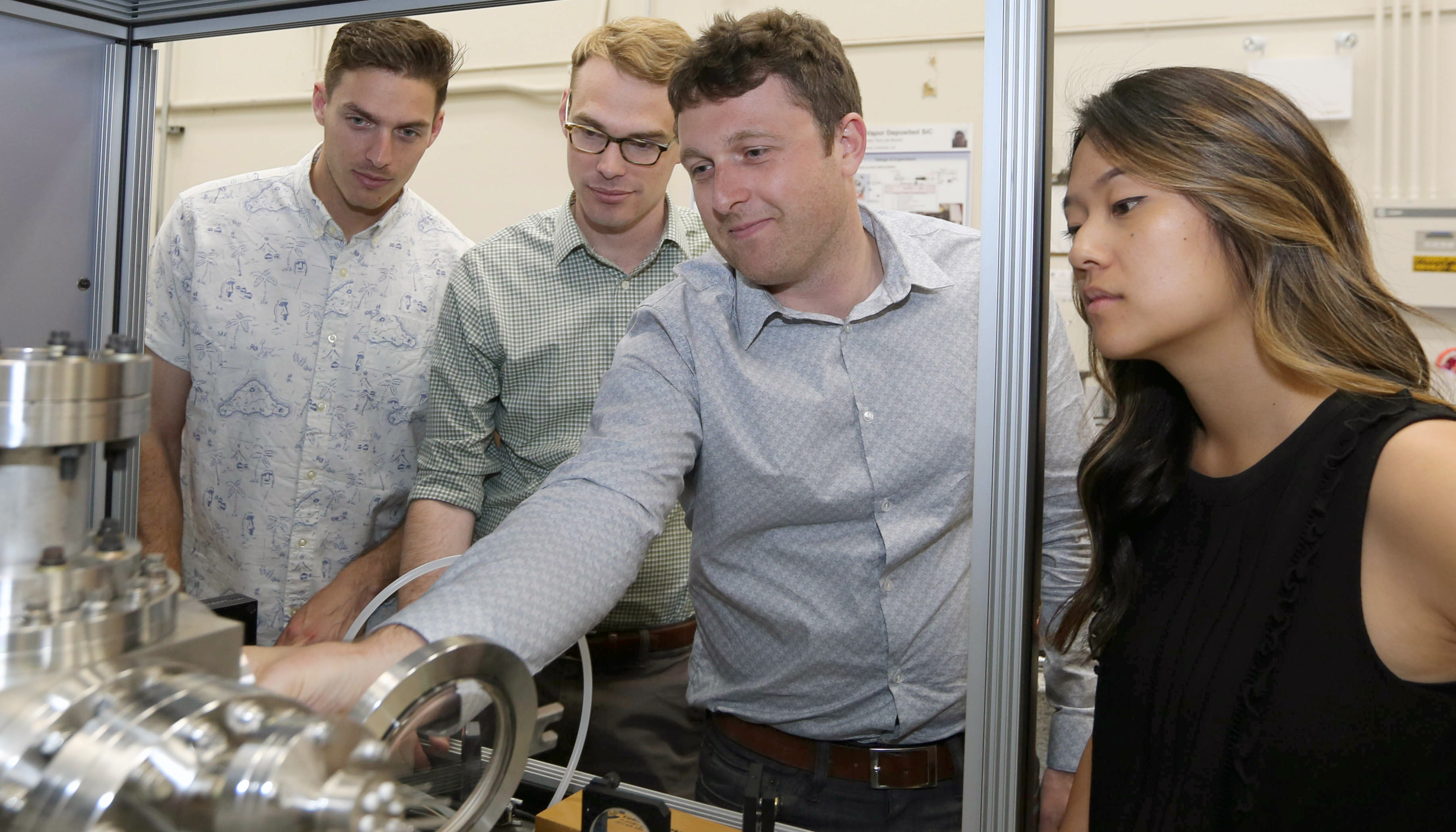

In order to carry out the project, LLNL researcher Nick Calta and his team have designed a portable diagnostic machine capable of probing the metal 3D printing process using X-ray imaging. The machine ultimately helped provide researchers with new insights into the metal additive manufacturing process. “A vast majority of diagnostics use visible light, which are extremely useful but also limited to analyzing the surface of the part,” explained Calta.

“If we’re going to really understand the process and see what causes flaws, we need a way to penetrate through the sample. This instrument allows us to do that.”

DOE funded laboratories investigate laser powder bed fusion process

The multi-year partnership between the laboratories is funded by the Department of Energy (DOE)’s Energy Efficiency and Renewable Energy (EERE) Advanced Manufacturing Office. Both SLAC and AMES are DOE laboratories, with LLNL also primarily funded by the federal agency. The collaboration between the laboratories is an offshoot of the DOE’s National Laboratories Big Ideas Summit (BIS).

The DOE’s BIS is an annual event intended to nurture collaboration and strategic technical planning in the national laboratory complex. The collaborative project established between the three laboratories reflects the BIS, with SLAC contributing its X-ray technology, and Ames Laboratory providing expertise in powders, metals and material science. “It’s a really nice team because each partner brings a strength,” said Tony Van Buuren, deputy division leader for S&T in LLNL’s Materials Science Division.

“The team is building a capability that is somewhat unique and providing information you can’t get any other way. Together we’re bringing in the diagnostics, spinning in science and spinning out the ability to look at new materials.”

Identifying pores in metal AM parts using X-ray imaging

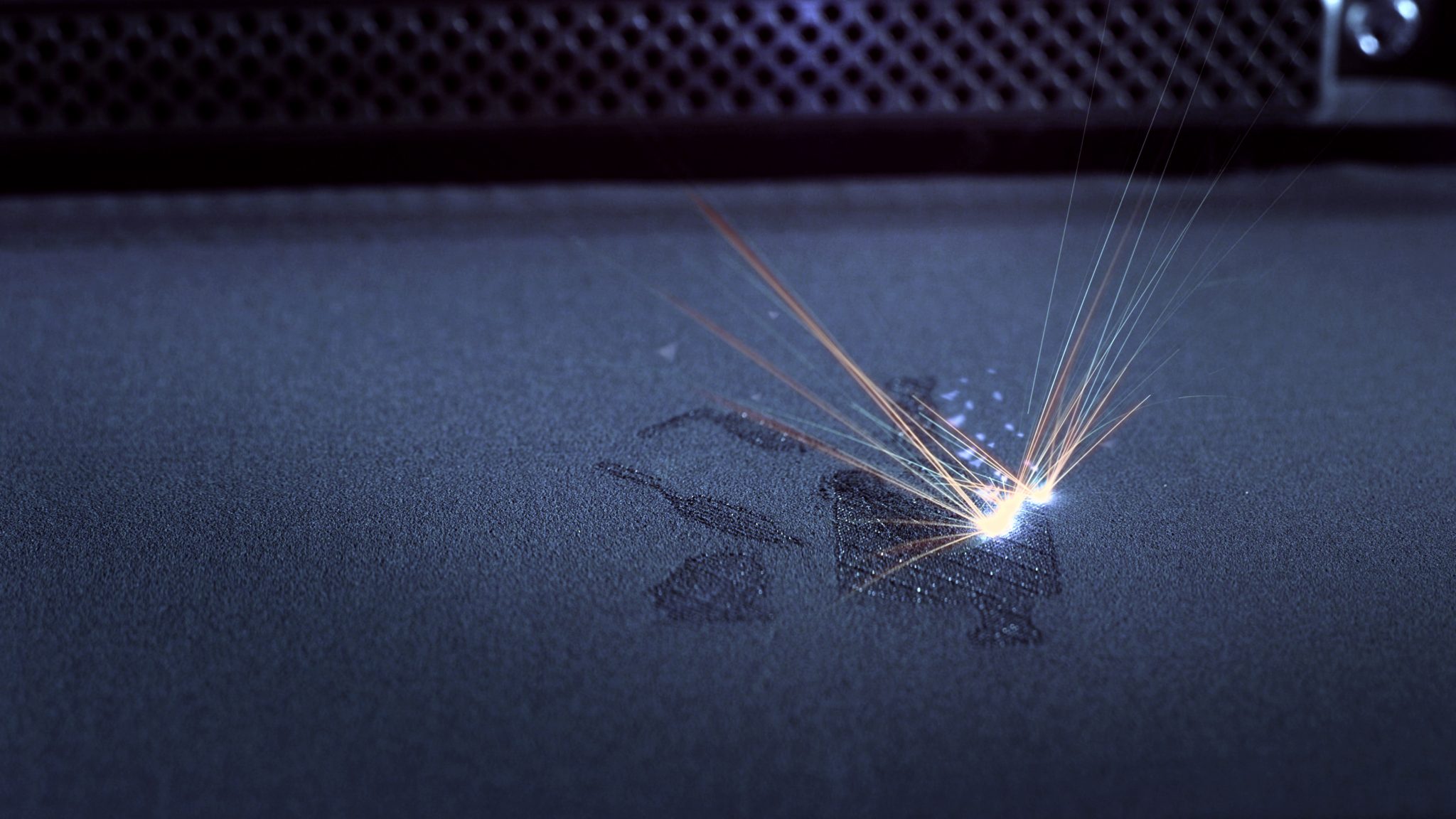

The portable diagnostic machine is designed specifically to observe and probe the melt pool during the laser powder bed fusion process. The melt pool is the area where the laser makes contact with the metal powder, enabling fusion and producing the layers that form the 3D printed part. It was assembled in situ, and proved difficult to construct due to the aggressive timeline of the research project, according to Calta. In order to make sure the instrument operated according to the intentions of the research, the LLNL team were required to transport it to SLAC. It was then fitted with SLAC’s ‘synchotron’, which was necessary to create high energy X-rays to investigate the samples.

Using the machine at the Stanford Synchrotron Radiation Lightsource at SLAC, researchers were able to successfully observe the dynamics of the melt pool beneath the surface. It provided meaningful data on a combination of imaging and X-ray diffraction, which helped researchers observe and understand how the metal solidified during laser powder bed fusion, a key determiner of a part’s strength.

“Success would be learning more about the physics in ways that let us modify the process to avoid defects,” continued Calta. “So far we’re getting promising results. We want to continue to optimize the instrument and apply it to different material systems. We already have a big body of knowledge based on optical data, this lets us branch out and complement that knowledge.”

Ibo Matthews, LLNL physicist, has said that the ability to observe the layer formation process of the melt pool and the comparison of X-ray images to simulations, has confirmed previously made predictions. These forecasted that a laser’s path, heat buildup and gas plumes created by the laser can establish defects in the printed part, like pores, which can cause cracking in the part when put under stress. Compiling the knowledge of defects with modeling and detailed experiments can potentially help to accelerate improvements and confidence in metal 3D printing, according to researchers.

Although the collaboration is still in its early stages, Calta has said that the researchers have quickly begun mapping out the formation of pores and identifying information on cooling rates already. With the X-ray imaging diagnostic machine, it is expected that the research will provide an improved understanding of laser fusion process, thus inciting further interest from various industries in metal 3D printing. “We’re getting information about the melt pool structure and what can go wrong during a build,” said Matthews. “The vapor plume created by the laser heating the melt pool can create pockets and pores.”

“These pore defects can serve as stress concentrators and compromise the mechanical properties of the part.”

Additive manufacturing at LLNL

Further LLNL researchers who worked on the project include Jenny Wang, Aiden Martin, Gabe Guss and Phil DePond, as well as contributors from SLAC and Ames Laboratory.

In this year alone, LLNL has been involved in multiple research projects involving additive manufacturing. The laboratory was recently reported to be developing a commercial-grade, metal additive manufacturing system. Funded by national 3D printing development partner America Makes, the project is designed and built in collaboration with GE Global Research, with the aim of developing a platform that could cut metal processing times in half.

LLNL researchers have also 3D printed micro-sized mechanical logic gates. These logic gates can be embedded into materials to make them respond to environmental stimuli and gather data without electronics.

Finally, in a slightly more unconventional project, researchers from LLNL have also used 3D bioprinting to produce live yeast cells capable of creating a substance similar to beer.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Lawrence Livermore National Laboratory researchers (from left) Phil Depond, Nick Calta, Aiden Martin and Jenny Wang. Photo via LLNL.