Researchers from the Lawrence Livermore National Laboratory (LLNL) have used 3D bioprinting to produce live yeast cells capable of creating a substance similar to beer.

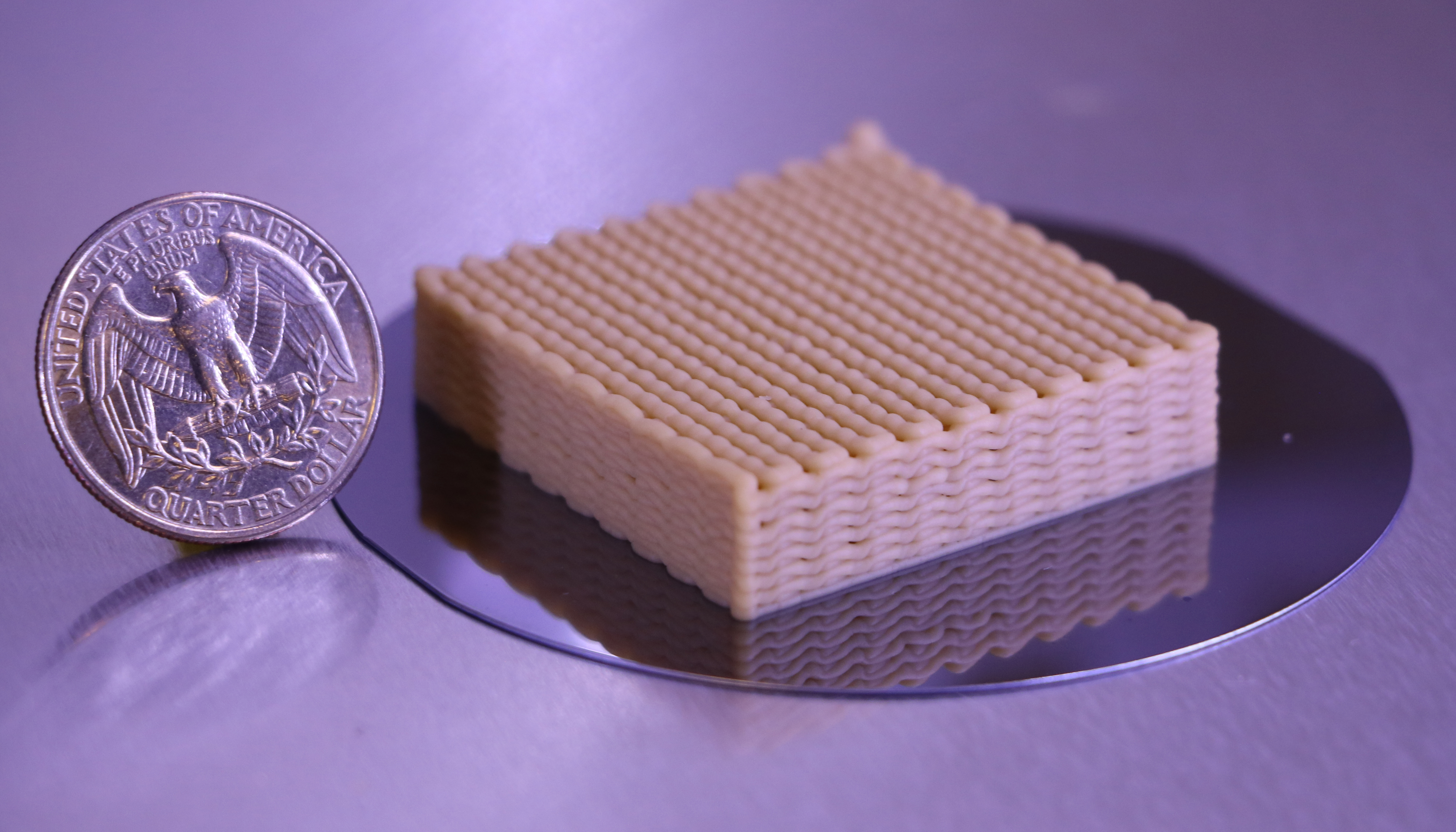

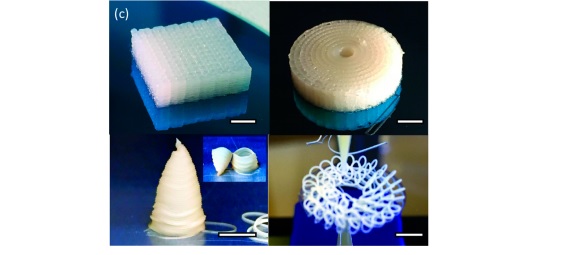

This bioink material is 3D printed into porous scaffolds, enabling the conversion of microbes, that is, glucose into ethanol and CO2. As a result of this chemical reaction, the study published in Nano Letters, has demonstrated the applicability of such additively manufactured cells for producing valuable end-product chemicals for the food industry, biofuel production, and waste treatment.

“This is the first demonstration for 3D printing immobilized live cells to create chemical reactors,” said Dr. Eric B. Duoss, an LLNL engineer and a co-author of the research.

Efficient ethanol production

Ethanol is a renewable chemical compound made from corn and other plant materials. It can be found in alcoholic beverages, motor fuel, food additives, beauty and cleaning products. The LLNL team 3D printed freeze-dried live biocatalytic yeast cells, known as Saccharomyces cerevisiae, into complex structures to foster the conversion of glucose to ethanol and CO2.

The team’s unique bioink substance allowed for self-supporting structures with high resolution and high catalytic activity. Dr. Duoss added, “this approach promises to make ethanol production faster, cheaper, cleaner and more efficient.”

“Compared to bulk film counterparts, printed lattices with thin filament and macro-pores allowed us to achieve rapid mass-transfer leading to [the] several-fold increase in ethanol production,” explained Fang Qian, LLNL materials scientist, and the lead author of the paper.

“The bioprinted 3D geometries developed in this work could serve as a versatile platform for process intensification of an array of bioconversion processes using diverse microbial biocatalysts for [the] production of high-value products.”

3D printed yeast

According to Sarah E. Baker, chemist and corresponding author on the paper, 3D bioprinting allows for the control over cell density, placement, and structure in living material. These properties can increase the production rates of ethanol and CO2.

Previously, Alshakim Nelson, Assistant Professor of Chemistry at the University of Washington began using ferment yeast with a 3D printer to create ethanol. Professor Nelson and his team, are also furthering their research in order to convert liquids such as fruit juices into alcohol, as well as to produce other substances such as proteins.

The research“Direct Writing of Tunable Living Inks for Bioprocess Intensification” is co-authored by Fang Qian, Cheng Zhu, Jennifer M. Knipe, Samantha Ruelas, Joshuah K. Stolaroff, Joshua R. DeOtte, Eric B. Duoss, Christopher M. Spadaccini, Calvin A. Henard, Michael T. Guarnieri, and Sarah E. Baker.

For more on 3D printing in academia, subscribe to the 3D Printing Industry Newsletter, follow us on Twitter, like us on Facebook.

Furthermore, join 3D Printing Jobs for opportunities in additive manufacturing.

Featured image shows an artist’s interpretation of a printed spiral filament loaded with live cells. Image by Ryan Chen/LLNL.