Lawrence Livermore National Laboratory (LLNL) researchers have 3D printed micro-sized mechanical logic gates. These logic gates can be embedded into materials to make them respond to environmental stimuli and gather data without electronics.

Andy Pascall, a chemical engineer and co-author of the research, said, “Certain electric applications are limited, whereas with this system, the material could completely reconfigure itself […] If you embedded logic gates into material, that material could sense something about its environment.”

“It’s a way of having a responsive material; we like to call it a ‘sentient’ material — that could have complicated responses to temperature, pressure etc. The idea is it’s beyond being smart. It’s responding in a controlled, precise way.”

Either TRUE/FALSE or 0/1

Mechanical devices which can behave in a similar fashion to electrical devices can be very useful for collecting data in extreme weather conditions or places where electronic devices may not work such as areas with high levels of electromagnetic waves or radiations. As Robert M. Panas, a research engineer at LLNL, said, “We see this as simple logic being put into high-volume materials, potentially getting readings in places where you can’t normally get data.”

Such mechanical devices are designed using the mechanical logic gates, which are basic logical operations such as AND, OR, and NOT. These operations always have binary (Boolean) values, TRUE/FALSE in propositional logic or 0/1 in computational logic. They take two or more inputs to yield a single result.

For example, in propositional logic, both sides of the AND statement must be true for the whole proposition to be true. In binary logic, this relation is represented using by the digit 1 (TRUE).

Mechanical logic gates

The logical operations of an electronic device use volts as values and each logic gate (operation) is represented by a shape. From basic logical operations, more complex outputs like NAND, which stands for NOT (x AND y), can be derived.

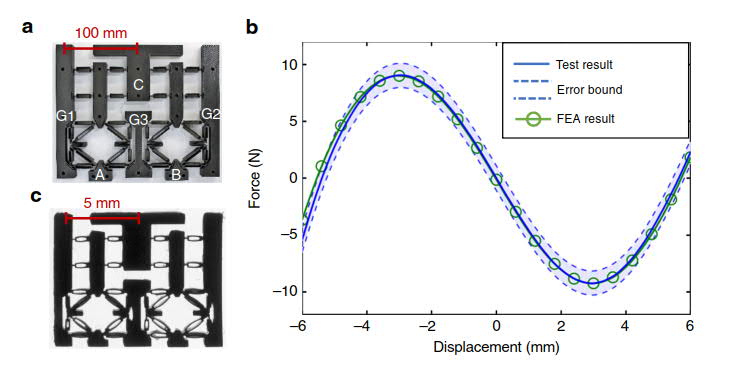

In a mechanical device flexure (bending or curving) can be used as switches much like the 0 and 1 or on/off switches in electric devices.

The LLNL researchers linked the flexures together to function as logic gates in response to light pulse or other similar external stimuli.

Panas explained, “Many mechanical logic designs have substantial limitations and you run into fanciful designs that could not be fabricated […] What we’re doing is using these flexures, these flexible elements that are 3D printed, which changes how the logic structure can go together. We eventually realized we needed a displacement logic setup (to transfer information). Surprisingly, it actually worked.”

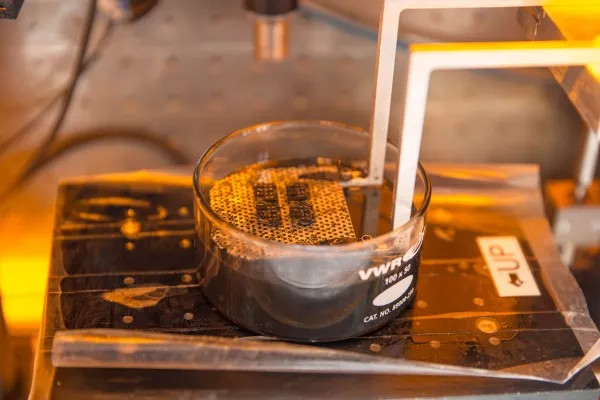

“Once the structure was printed, we then deformed it in place using different lasers that act as optical tweezers,” Hopkins explained. “We then actuated the switches using those optical tweezers as well. It’s a revolutionary new approach for making these materials at the micro-scale.”

Mechanical actuators

The mechanical logic gates can be embedded into different materials that could behave like actuators, changing the shape of the material by responding to external stimuli. Such materials can be used in soft robotics or on rovers on interplanetary missions.

Although mechanical logic gates have been made before, 3D printing has allowed the LLNL researchers to make them scalable from macro (in FDM/FFF) to micro, 3D printed using the Large Area Projection Microstereolithography (LAPµSL).

Pascall said, “The nice thing about our design is it’s not limited in scale.”

“We can go down to order of several microns up to as big as you need it to be, and it can be rapidly prototyped. This would be a difficult task without 3D printing.”

The research paper discussed in this article is titled, Additively manufacturable micro-mechanical logic gates published in Nature Communications. It was jointly authored by Yuanping Song, Robert M. Panas, Samira Chizari, Lucas A. Shaw, Julie A. Jackson, Jonathan B. Hopkins, and Andrew J. Pascall.

Nominations for 3D Printing 2019 awards are open now.

For more information on the groundbreaking research in additive manufacturing, subscribe to our 3D printing newsletter. You can also join us on social media: Facebook and Twitter.

Visit our 3D Printing Jobs site for a career in additive manufacturing.

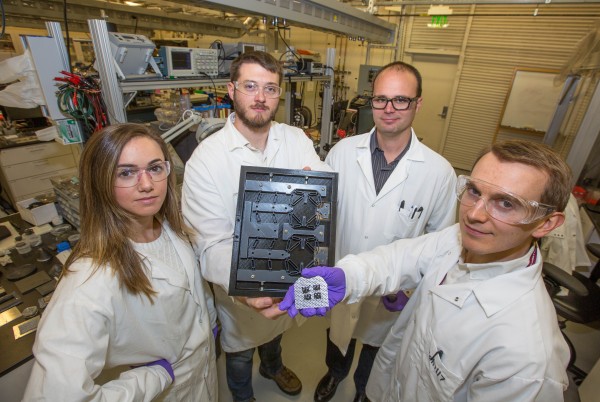

Featured image shows LLNL researchers, (from L-R) Julie Jackson Mancini, Logan Bekker, Andy Pascall, and Robert Panas. Photo courtesy of Julie Russell/LLNL.