A team working out how to maximize the amount of light emitted by LED lightbulbs has made a discovery using nanoscale 3D printing.

Through studying the natural light-producing capabilities of bioluminescent bugs, Penn State researchers have pinpointed the microscopic qualities of insects with the brightest glow. Using high precision 3D printing, the team then recreated these qualities. They have now produced a bright new patent-pending technology that they believe could have commercial applications for clean energy.

Professor Stuart (Shizhuo) Yin, corresponding author of the paper discussing this technology soon to published by Optik journal, explains, “LED lightbulbs play a key role in clean energy. Overall commercial LED efficiency is currently only about 50 percent. One of the major concerns is how to improve the so-called light extraction efficiency of the LEDs.”

“Our research focuses on how to get light out of the LED.”

Inspired by fireflies

The Penn State team’s LED research is a type of bioinspiration, based on the lanterns of fireflies and glowing spots of the Ecuadorian cockroach lucihormetica luckae. Though unrelated as species, the microstructure of these insects’ glowing parts is strikingly similar: both parts are patterned with rows of pyramids. The undulating structure of this pattern allows more light to escape the source instead of reflecting backwards and lost. Modern LEDs already share this type of structure with their insect relatives. However, the key finding of Penn State’s research is that the pyramids on firefly lanterns and cockroach spots are asymmetric, with varying angles.

“This is where I tried to go a little deeper into the study of light extraction efficiency using asymmetric structures,” explains study lead author and Penn State doctoral student Chang-Jiang Chen.

Ultrahigh light extraction efficiency

Using a nanoscale 3D printer, the likes of which are commercialized by Nanoscribe GmbH and Microlight3D, the Penn State team were able to recreate the asymmetric structure of insect lanterns and spots for further experimentation.

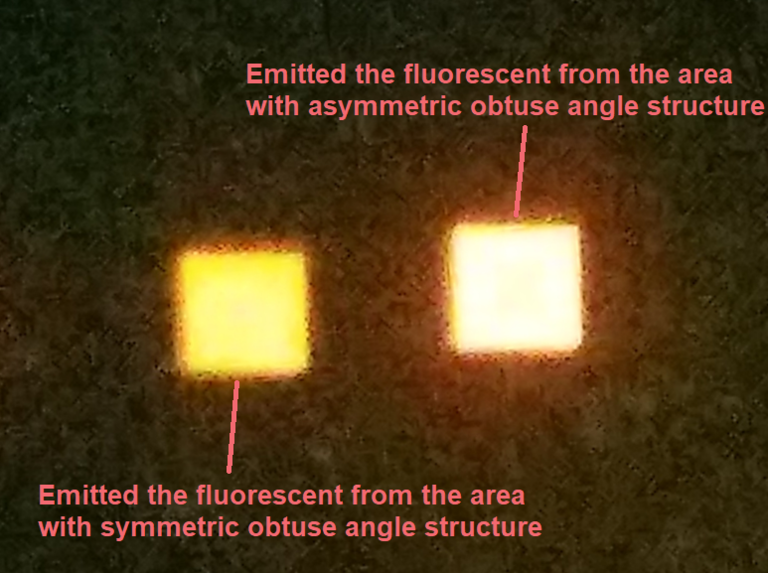

Compared to symmetrical pyramid patterns, the asymmetrical structures proved to increase the light extraction efficiency by up to 90%. This is due to the greater surface area of asymmetric pyramids, and the greater randomization of light reflections produced by the two different-sized slopes of the shape.

Applying this theory to the production of LEDs the team were able to create asymmetric arrays by changing just one step of the manufacturing process, thus delineating a compatibility with commercial production. As such, Penn State has now made a patent application for this production method, and the researchers are seeking industry partners to help take the project to the next step. Yin concludes, “Once we obtain the patent, we are considering collaborating with manufacturers in the field to commercialize this technology.”

“Ultrahigh light extraction efficiency light emitting diodes by harnessing asymmetric obtuse angle microstructured surfaces” is scheduled to be published in the April 2019 edition of Optik journal. It is co-authored by Chang-Jiang Chen, Jimmy Yao, Wenbin Zhu, Ju-Hung Chao, Annan Shang, Yun-Goo Lee and Shizhuo Yin.

Is this your 3D Printing Research Team of the Year? Nominate this Penn State team and more for the 2019 3D Printing Industry Awards now.

For more news on the latest additive manufacturing research, subscribe to our 3D printing newsletter. You can also join us on Facebook and Twitter.

Looking for a job in the industry? Then visit our 3D Printing Jobs board.

Featured image shows example 3D printed, asymmetric pyramid microstucture. SEM image via Penn State