Independent Netherlands-based photopolymer manufacturer Liqcreate has added a new elastic engineering resin to its 3D printing material portfolio.

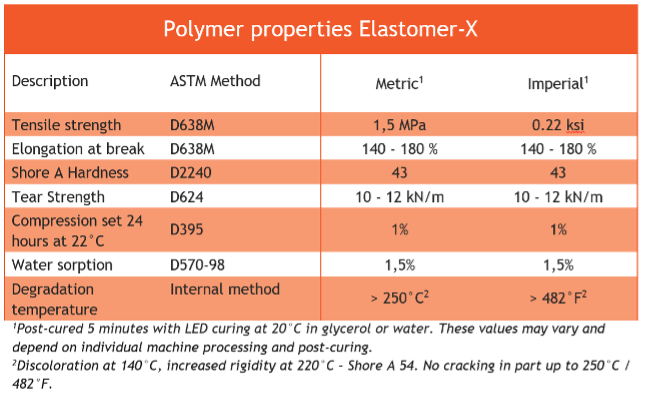

Designed to be one of the softest elastomer resins on the market, Elastomer-X features high elongation, good tear strength and a Shore A hardness of as low as 43, lending it a pliability akin to that of TPUs and silicones. Thanks to these properties, Liqcreate says its latest polymer is ideal for printing digital lattice foams, soft end of arm tooling (EOAT) for robots, grommets, bellows and elastic industrial parts.

Liqcreate’s flexible resin range

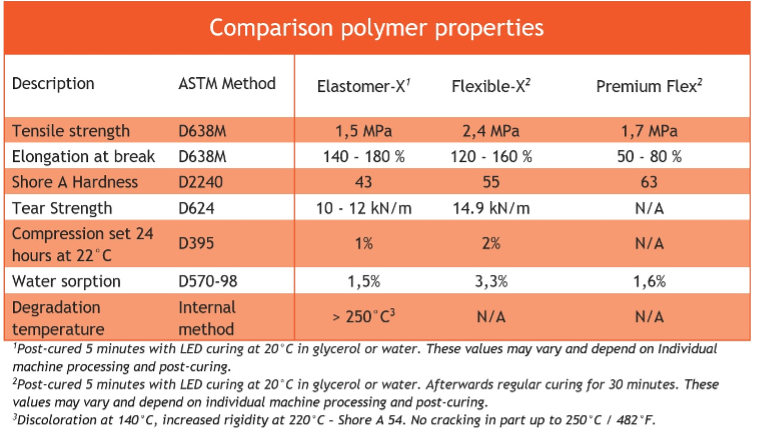

With the launch of Elastomer-X, Liqcreate now offers three commercial flexible and elastic resins under its own brand, each of which is designed to address a distinct application area. The most rigid of these, Premium Flex, has a Shore A hardness of 65. However, the material is still flexible and soft, in a way that could make it perfect for those seeking a soft resin that’s well suited to rapid prototyping.

By contrast, the firm’s Flexible-X resin has a Shore A of 55, making it slightly softer, and it’s also said to feature good tear strength. According to Liqcreate, these qualities make it an excellent material for covering engineering-type applications.

Going a step softer again, the company’s latest polymer, Elastomer-X, has an even lower Shore A, making it the softest in its range. With a tear strength of 10-12 kN/m, the resin is also one of the most tear-resistant materials in its class. As such, it’s thought the plastic could soon find extensive applications as a TPU or silicone replacement.

Designed to be compatible with open SLA, DLP, and MSLA systems in the 385-420 nm range, Liqcreate’s TPU-like material is said to be characterized by excellent elongation, good tear strength and elastomeric properties. These qualities, which the resin has demonstrated via testing, combine to make it ideal for creating an array of highly-elastic industrial components.

In terms of coloring, Elastomer-X ships as a clear liquid, hence resulting prints will feature a clear (albeit slightly hazy) finish. The material’s appearance can be changed with almost any commercial resin colorant, something that could be ideal for creating opaque elastic parts. Detailed information regarding coloring can be found via the Liqcreate website.

Exploring elastomeric applications

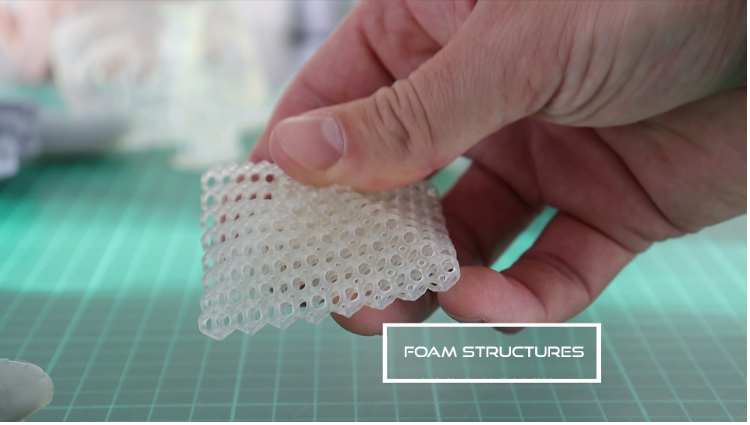

There are plenty of potential applications out there for extremely soft resins with a high level of tear strength. Such materials not only enable the creation of soft lattice structures capable of mimicking the behavior of foams, but they could be useful in robotics too. In place of silicone, it’s possible that users can 3D print Elastomer-X into soft, skin-like structures, or manufacture industrial robotic grippers and fingers.

Elsewhere, Liqcreate’s broader resin R&D and production efforts in the fields of SLA, MSLA, and DLP 3D printing, continue to unlock applications in the medical, industrial, automotive and consumer goods sectors. This range, which now spans premium, creative, engineering, castable and general purpose resins, has rapidly expanded in recent years.

Alongside its general-purpose polymers, which are designed to provide users with a high level of print accuracy and a smooth finish, the firm has launched the high-throughput MSLA focused Premium Tough and Premium Flex. For those seeking to make ultra-rugged parts, Liqcreate has also introduced the Tough-X, Flexible-X and Composite-X photopolymers, with a variation of strong impact-resistance and rebound properties.

With the latter, the company has added an ultra-stiff resin to its portfolio that offers completely different characteristics to the rest of its range. The polymer is reinforced by micro-nano particles, in a way that provides it with excellent strength, and once heated, it reacts by becoming much more rigid than conventional photopolymers.

Elsewhere, for dental customers, Liqcreate has launched its Premium Model, Dental Model Pro and Gingiva Mask materials, as well as its Wax Castable resins. Between them, these enable the creation of dental aligner models with low shrinkage and high dimensional stability, in addition to soft tissue, gum-like parts for dental implant models.

Designing the ideal 3D printing resin

In tandem with its branded resin range, Liqcreate also offers to develop custom materials for those in need of a non-standard formula for a specific application. Through this OEM service, customers can request the development of a polymer with precise characteristics, which impact its print speed and color, as well as the properties of resulting parts.

When it comes to elastic or flexible resins, clients can even request the formulation of materials with a Shore A hardness of anything from 30 to 100. Once customers have started a custom material development project, Liqcreate’s engineers work to develop a resin according to their specifications, and provide guidance on how to dial in their new resins for a given printer, preparing them for production.

As an independent resin manufacturer with R&D facilities, Liqcreate is also able to rapidly scale its production of custom-made resins where needed. What’s more, the company’s standalone nature means there is little to no competition or conflict when working with 3D printer hardware manufacturers. As such, the firm is able to work quickly and get resins to market in quantity, without encountering issues that might otherwise keep clients waiting.

Potential customers can find out more about the firm’s material portfolio by visiting the Liqcreate website or reaching out to a Liqcreate representative or dealer to learn more about the new Elastomer-X photopolymer 3D printing resin.

Nominations for the 2022 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Let us know by casting your vote now.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a set of robotic fingers 3D printed from Liqcreate’s Elastomer-X resin. Image via Liqcreate.