Link3D, a New York-based 3D software company, has unveiled a new additive manufacturing workflow solution called Quality Management Systems (QMS) at Formnext 2019.

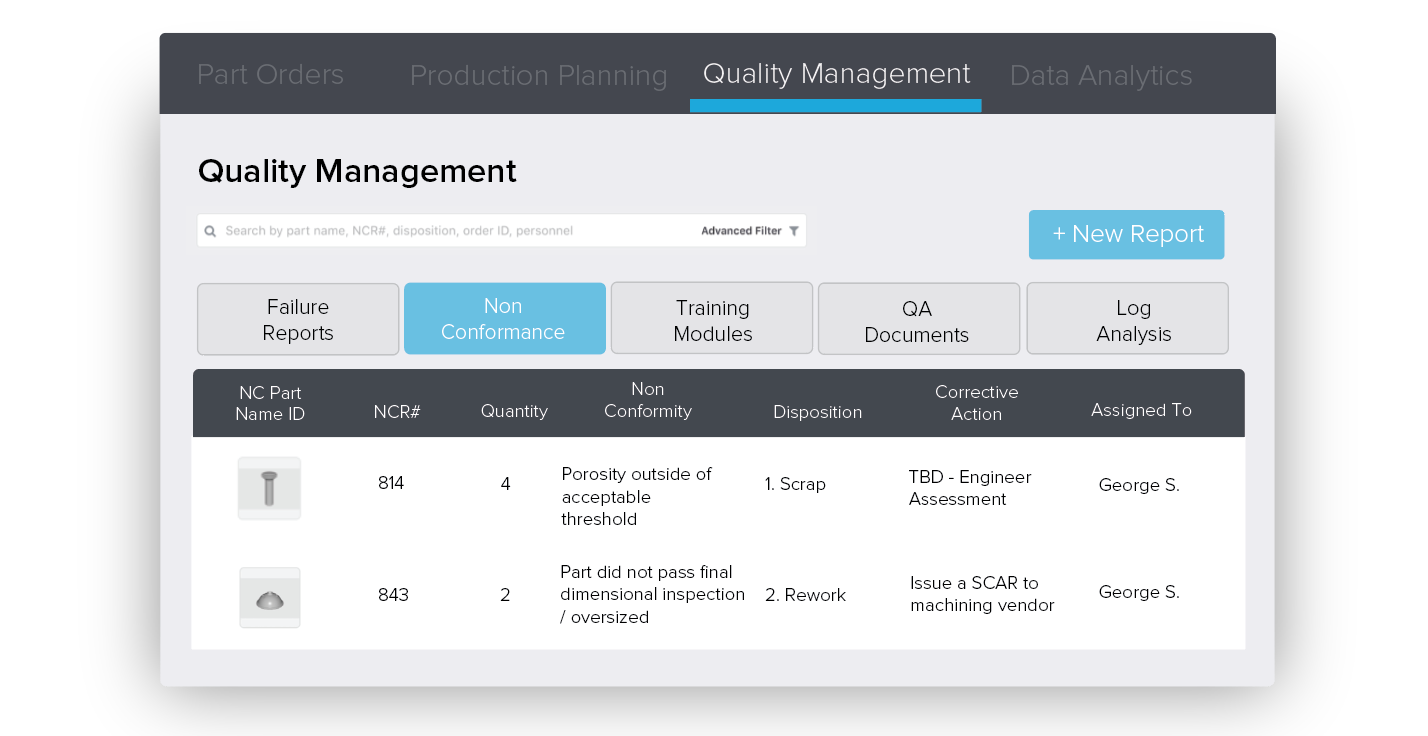

The QMS software is designed to boost 3D printing part performance, compliance and safety on the factory floor. It allows users to improve the quality of their 3D printed parts through end-to-end quality data traceability, which provides increased transparency for the additive manufacturing workflow. This also enables companies to detect process failures and defects throughout the Digital Thread according to regulatory standards, proving useful for the aerospace, automotive and medical industries.

“QMS has been a missing piece of the additive manufacturing puzzle. We’ve been working with machine manufacturers, material suppliers and industry leaders in highly regulated sectors such as Aerospace, Automotive, and Medical,” comments Shane Fox, CEO of Link3D. “Part repeatability for compliance is an ongoing challenge organizations face.”

“As quality standards mature alongside materials and machines, Link3D will help businesses ensure repeatability of their qualified workflows, including ‘machine, material and part qualification programs’ powered by data management.”

Full traceability in Link3D’s Quality Management Systems

Using Link3D’s QMS, firms will be able to track a 3D printed part’s lineage as it travels through the supply chain. In tracking the part, QMS captures its quality data from material procurement, part design, build preparation data, production parameters, post-processing, and final quality inspections. Furthermore, Link3D states that data can also be procured when the part is actually in use, ensuring conformance to customer requirements.

“Quality Management Systems designed for Additive Manufacturing will be a gamechanger; enabling businesses to ensure repeatable quality production, increasing production performance, meeting audit and compliance requirements while improving safety on the production floor,” explains Vishal Singh, CTO of Link3D.

Creating an extensive quality thread for the manufacturing process can be particularly useful for highly regulated industries, explains Link3D. As well as improving part quality and reducing costs, Link3D’s QMS platform can also demonstrate part conformance through the generation of quality reports. Users can also develop risk assessment and mitigation plans, and identify the root cause for any adverse events within the 3D printing process chain.

“Businesses looking to scale additive manufacturing can look forward to built-in quality feedback loops at micro and macro levels, enabling continuous improvement, and facilitating and maintaining part qualification programs in a systematic way built on top of unified data architecture,” adds Singh.

Link3D partners with EOS and Autodesk

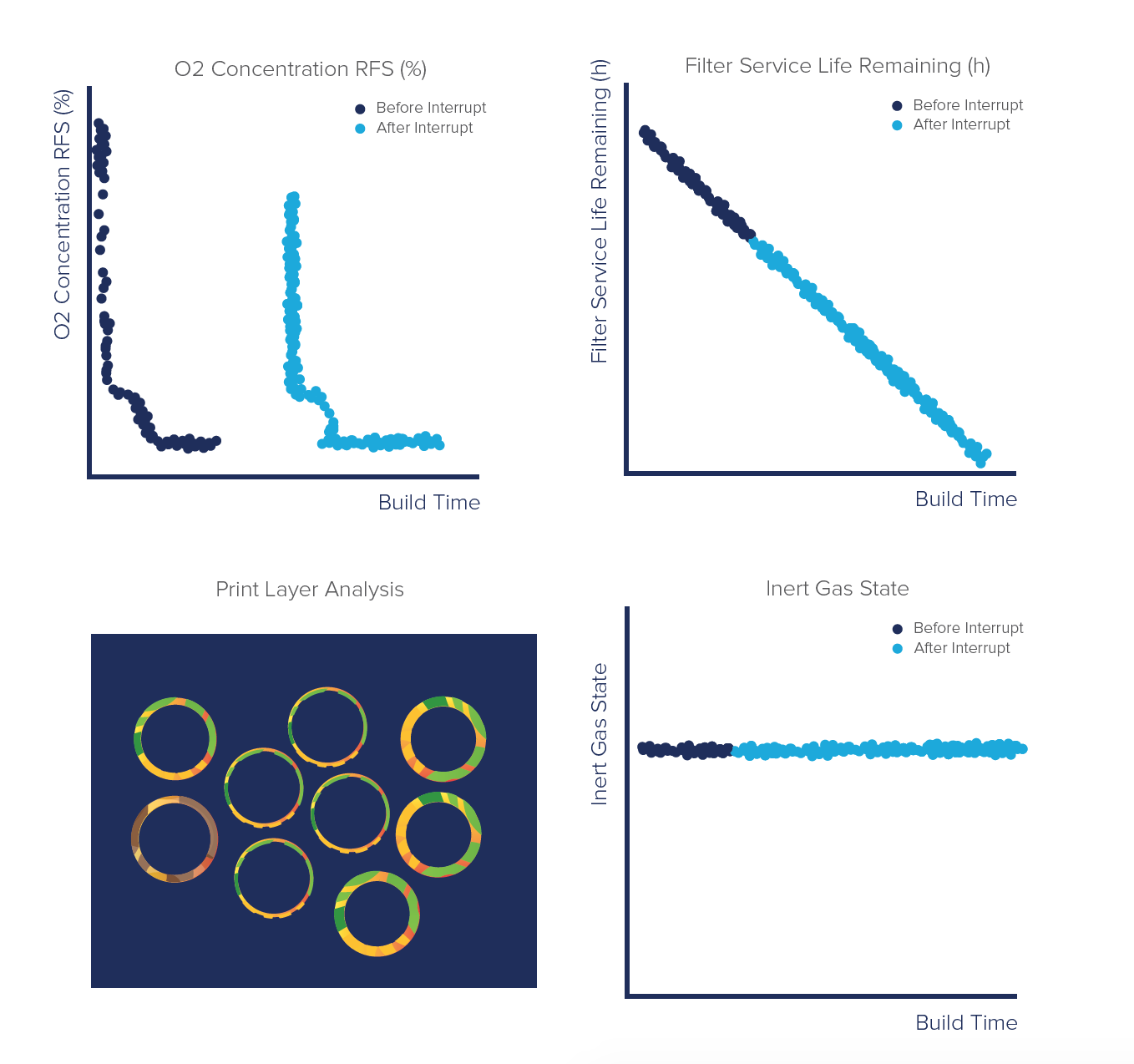

Link3D recently expanded its partnership with EOS, a leading German 3D printer OEM. Working in a joint machine connectivity program, the two partners are enhancing Link3D’s Production Scheduling software to help streamline the additive manufacturing process.

The company is also collaborating with 3D software company Autodesk to enable full traceability within additive manufacturing processes. Together the partners will integrate a new workflow that connects Link3D Additive MES bidirectionally into Fusion 360 and Netfabb. Both partnerships were also unveiled to the public at Formnext 2019. You can visit Link3D at the show in Hall 11.0, Booth F41.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Link3D QMS – Part Non-Conformance Management. Image via Link3D.