Optomec, Albuquerque based developers of Directed Energy Deposition and Aersol Jet metal 3D printers, has released a new software tool that will accelerate the use of additive manufacturing for repair.

AutoCLAD is a proprietary integrated vision and software system that generates a custom toolpath for each part prior to processing. It was initially developed under Optomec’s Huffman brand and the software has already been put to the test by enterprises working with aircraft engines and industrial gas turbines to repair both worn and damaged components.

The AutoCLAD vision system software can be used with Optomec’s range of LENS metal additive manufacturing systems.

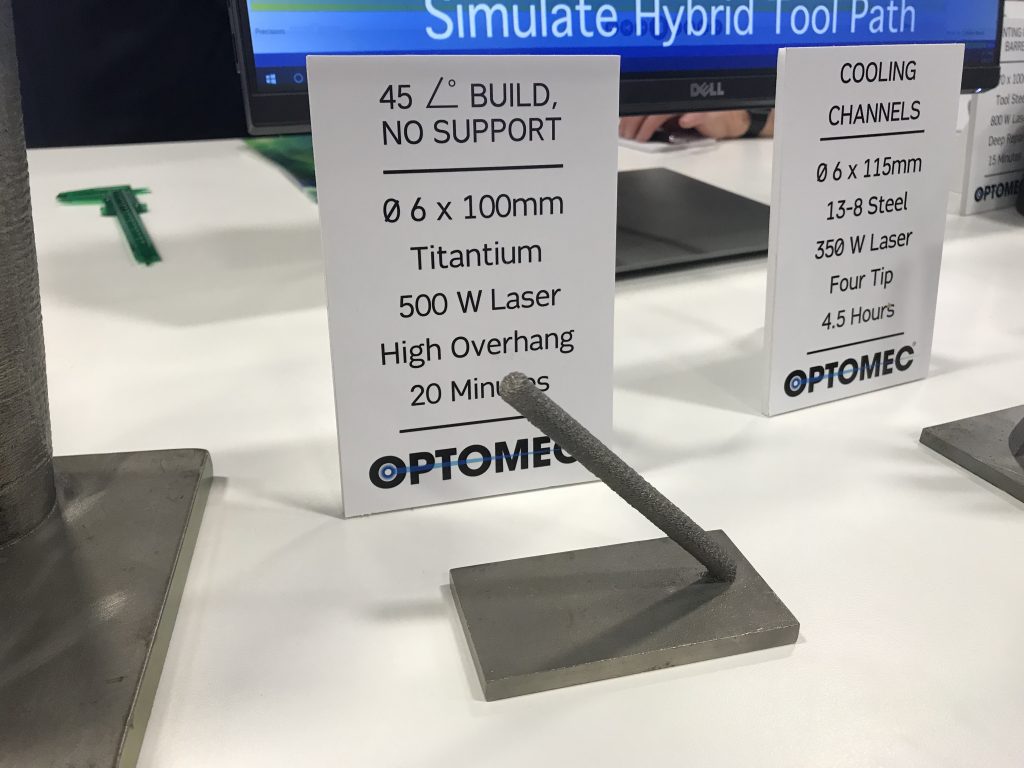

Adding this capability to the LENS brand of solutions will enable customers to use automated DED for the repair of reactive metals like titanium in a controlled, argon atmosphere. It also brings the AutoCLAD technology to hybrid Additive Manufacturing–combining additive manufacturing and machining capabilities in a single system.

AutoCLAD images the part and then automatically adapts and modifies the toolpath and DED parameters for each individual part based on variations in orientation, dimension, and shape. It not only adjusts the toolpath for variation, but it also adapts laser power to reduce the heat input into thinner areas, which drastically reduces the heat-affected zone (HAZ) of the finished part. Finally, by fine-tuning the toolpath for the individual part, a smaller overbuild is achieved which significantly reduces the final machining time after the additive manufacturing process.

“This latest enhancement combines three important technologies developed by Optomec into a single system. Combining the capabilities of AutoCLAD with Optomec’s industry-leading controlled atmosphere technology and hybrid manufacturing solutions enables the processing of reactive metals without oxidation, and allows Additive Manufacturing and machining in a single system. No other company has this combination, in fact, no one has software like AutoCLAD,” said Mike Dean, Marketing Director at Optomec. “We see this as a big win for customers who want to use DED for the repair of titanium components as well as anyone doing repetitive part repair in industries such as oil and gas, mining, and tool and die .”

The AutoCLAD system is available immediately as an upgrade for all Optomec LENS systems that use the Siemens 840D controller, which includes the LENS CS 600, CS 800, CS 1500, and MTS 860 machines.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Optomec LENS 860 closed atmosphere hybrid additive manufacturing system. Photo by Michael Petch.