New York Additive Manufacturing Workflow Software developer Link3D has announced the launch of the Additive Material Recommendation System (AMRS). Integrated within the workflow of the company’s additive manufacturing execution system (AMES), AMRS allows engineers to filter available materials based on qualitative characteristics and technical properties.

“One of the major recurrent hurdles we’re hearing from our customers is how to accelerate the adoption of additive manufacturing within their own organization,” explains Renaud Vasseur, VP of Business Development & Sales at Link3D. With the addition of this new feature, the company will help its end users achieve their goals, and Vasseur adds, “increase overall understanding of the additive manufacturing capabilities and workflows.”

Link3D AMES and Additive Workflow Software

Founded in 2016, Link3D develops and provides software for additive manufacturing OEMs and service bureaus. Features of Link3D software include part ordering, auto-quoting, build time simulation, production planning post processing management, digital part inventory and data analytics.

Link3D customers are found all across aerospace, automotive, medical and consumer industries. As of December 2018, its AMES and Additive Workflow Software are integrated within EOS North America’s operations.

Inside the Additive Material Recommendation System

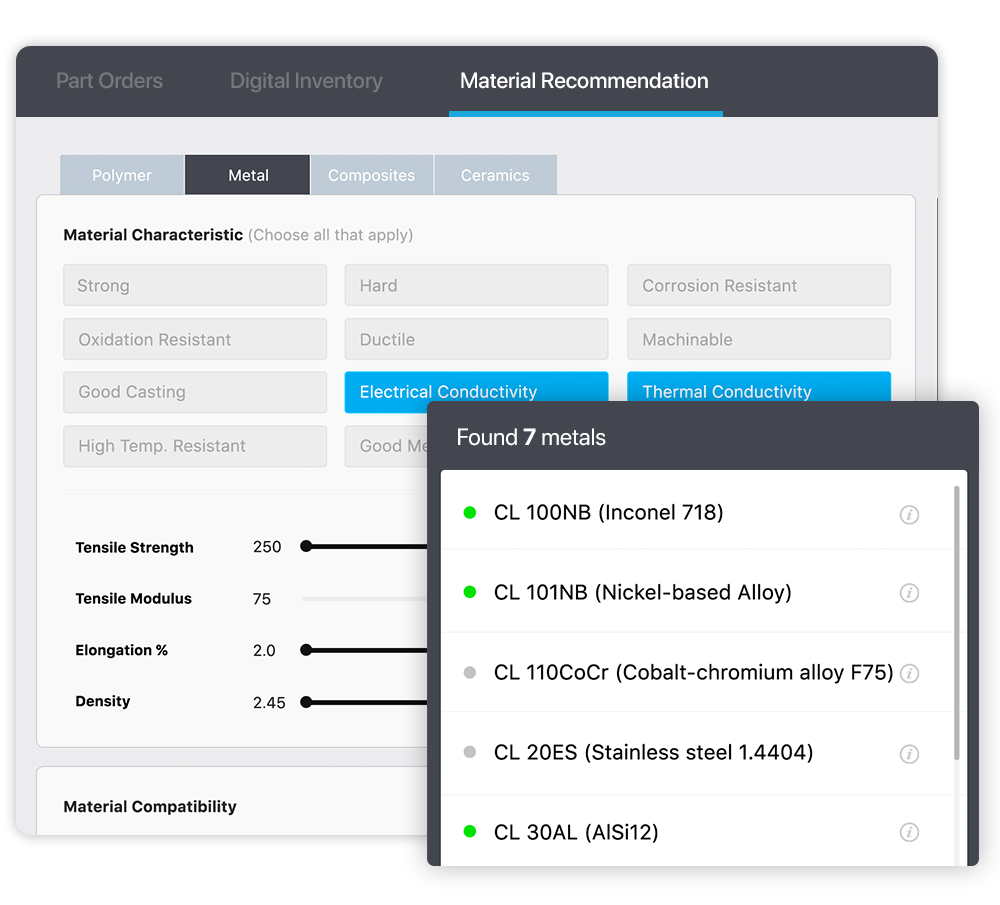

AMRS is a new feature for AMES designed to tackle challenges in additive manufacturing’s adoption throughout an organization. For those new to additive, AMRS is an invaluable tool for helping to select the correct material for purpose. For experienced engineers, the AMRS facilitates faster decision making and frees up their time for more value-added activities.

In the AMRS feature, both metal and polymer materials can be filtered in three ways:

1. By qualitative characteristics, i.e. rigidity (for polymers) corrosion resistance (metals), high temperature resistance.

2. By technical properties, e.g. tensile strength, hardness.

3. By material manufacturer, this includes EOS, Concept Laser, Trumpf, Stratasys, Carbon, Renishaw, HP, Additive Industries and more.

The adoption of the new AMRS feature contributes to Link3D’s overall vision for the future of additive manufacturing. Speaking in 2018, Shane Fox, co-founder and CEO of Link3D, said he expected to “see an increase in collaboration between software and hardware,” which would “help industries advance their additive manufacturing facilities towards mainstream manufacturing.”

Is Link3D your Software Company of the Year? Nominate them and more for the 2019 3D Printing Industry Awards.

For more of the latest 3D software updates and other news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. For new opportunities in your field join 3D Printing Jobs.

Featured image shows the Link3D Digital Factory user interface where parts are designed and produced. Image via Link3D.