Lawrence Livermore National Laboratory (LLNL) has published research into 4D printed silicones. LLNL combines its direct ink writing method with shape memory polymers to create silicone structures that can recover from periods of compression.

The shape changing silicone structures could have a broad range of applications, especially in the medical industry. ETH Zurich researchers recently created a silicone artificial heart with 3D printing and by adding shape memory polymers LLNL could perhaps extend the life of the structure.

LLNL envisages its 4D printed silicone structures could have application in “wearable protective padding” which would activate under certain temperature conditions.

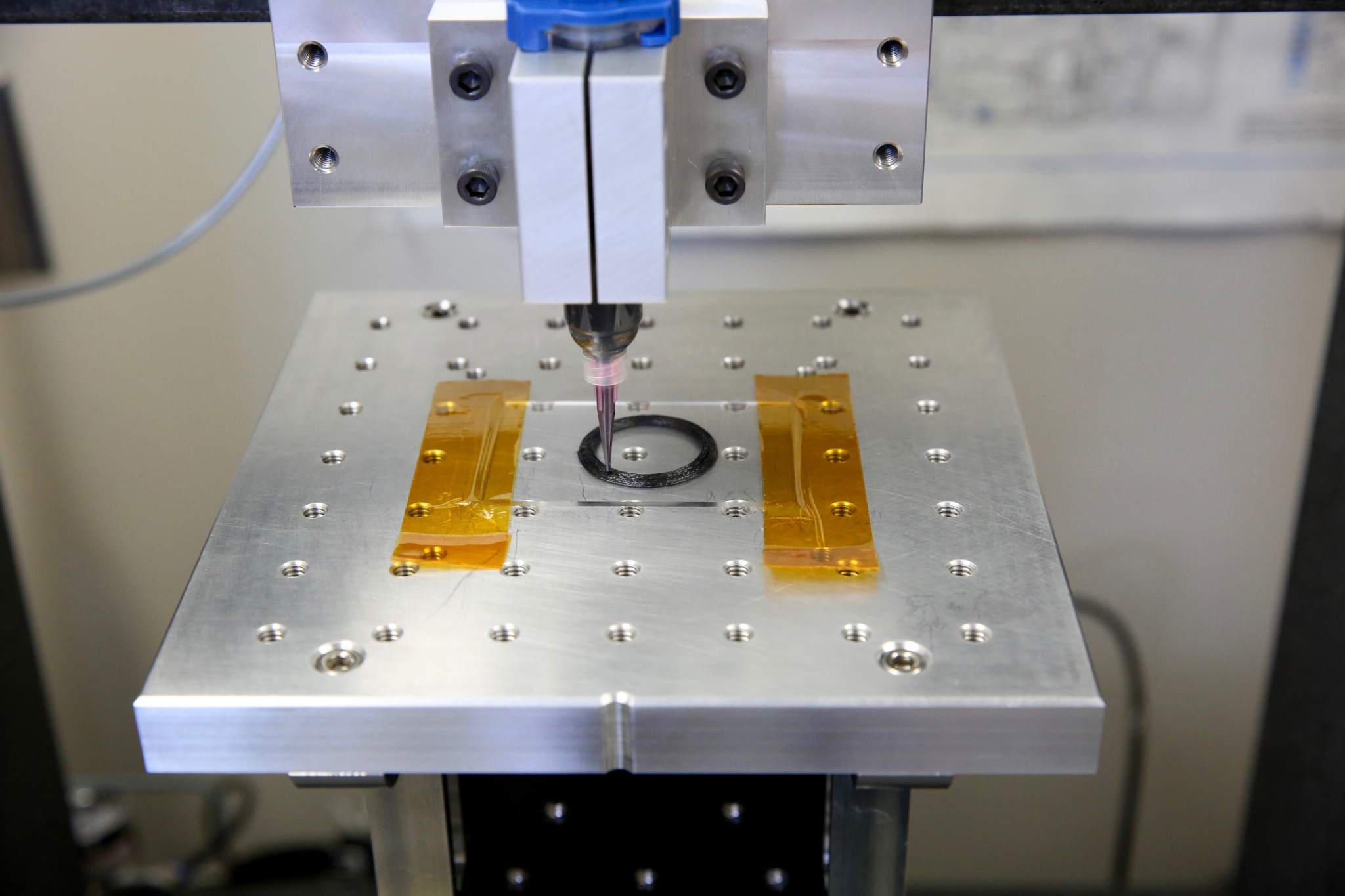

Direct ink writing (DIW)

While silicone is a particularly desirable material for 3D printing, it is also quite difficult to form 3D structures with. Other researchers have utlized water to create 3D printed silicone, but LLNL opted for its direct ink writing technology.

Lawrence Livermore has implemented its direct ink writing technique in a number of recent projects. This includes its latest breakthrough into 3D printed glass and a modified approach to create aerospace grade carbon fiber composites.

The method involves use of viscoelastic inks which are materials with both viscosity and elasticity. In this project, LLNL combined silicone inks with a shape polymer shell.

Shape memory

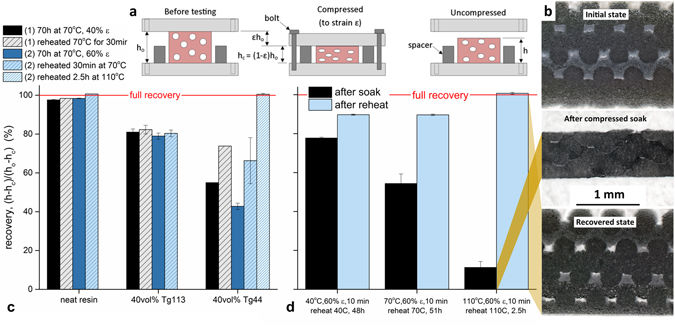

As the paper explains, using shape memory polymers adds another layer of functionality to 3D printed parts. The method is widely known as 4D printing and a number of groups have demonstrated the usefulness of the technique – such as Chinese surgeons who 4D printed an advanced breast implant. However the paper explains how its silicone approach is novel,

Here, for the first time, we demonstrate that shape memory can be achieved in 3D printed porous elastomers simply by the addition of polymer microspheres with controlled shell glass transition temperatures.

The team tested the shape memory by compressing the structures before thermal soaking and successfully restored the object’s shape. As a result, the researchers explain its future work will “include multi-material printing and in-line mixing, to further tune structure, porosity and material properties.”

The research paper, titled ‘3D Printed Silicones with Shape Memory’ has been published in Scientific Reports.

For all the latest 3D printing research news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows Figure 1d-g from the paper shows the printing process and microscopic images of the printed structures. Image via Scientific Reports.