In 2017 at the Karlsruhe Institute of Technology (KIT) in Germany, researchers succeeded in 3D printing, and erasing, microscopic structures 5 times the size of a human hair. An important step forward for high-resolution applications such as medical biopritning and microelectronics, the team has added a new level of sophistication to its research with multiple, erasable inks.

Micro 3D printing

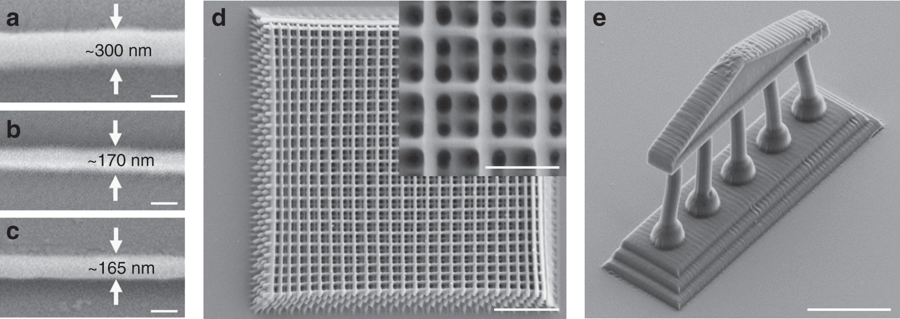

Microfabrication at KIT is performed used a Photonic Professional GT two-photon lithography 3D printer from Nanoscribe Gmbh. The scale of the 3D micro structures produced in this particular study is below 50 μm – the average width of a human hair. To add a little more perspective, the longest chromosome in the human body is 10 μm long which is, incidentally, the same as the scale bar used on figures in the KIT study.

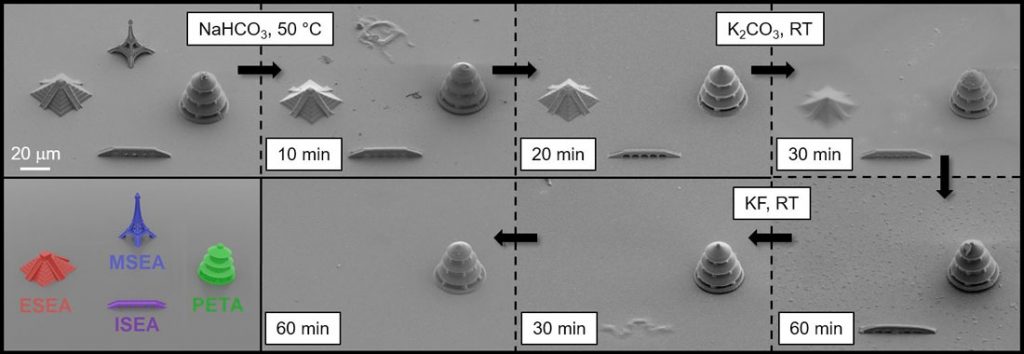

In total, the degradation of four different 3D printer inks is observed in this research: MSEA, ESEA, ISEA and PETA.

Wiping out the Eiffel Tower

After 3D printing each of the structures, the sample plate is submerged within chemical baths heated at 50 °C. In the first bath, the Eiffel Tower, made using MSEA, degrades within 20 minutes though the other three structures remain stable.

Next, in exposure to another chemical, an Aztec temple of ESEA took around 1 hour to degrade. Then, in a further test, ISEA was completely removed, again taking 1 hour.

Crucially, at the end of the three so-called “cleavage steps”, the Asian temple made from PETA remained as a reference structure.

In conclusion, “…we submit that the class of photoresists presented here hold large potential and will allow for the fabrication of a variety of complex and multifunctional 3D nano- and microstructures that are presently inaccessible using current state of the art photoresists and/or subtractive manufacturing methodologies.”

The team also believe that their inks could be used in other 3D printing technologies like SLA, and DLP.

“Adding chemically selective subtraction to multi-material 3D additive manufacturing” is published open access in Nature Communications journal. It is co-authored by David Gräfe, Andreas Wickberg, Markus Michael Zieger, Martin Wegener, Eva Blasco and Christopher Barner-Kowollik.

For all the latest cutting edge research reports, subscribe to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter. For new, professional opportunities in the industry, search 3D Printing Jobs.

Featured image shows micro monuments 3D printed as test structures in KIT’s erasable ink study. Image via Nature Communications, Supplementary Information