Open-source 3D printing enthusiast Johan Von Konow has released his latest DIY project, a modular 3D printable MIDI synth.

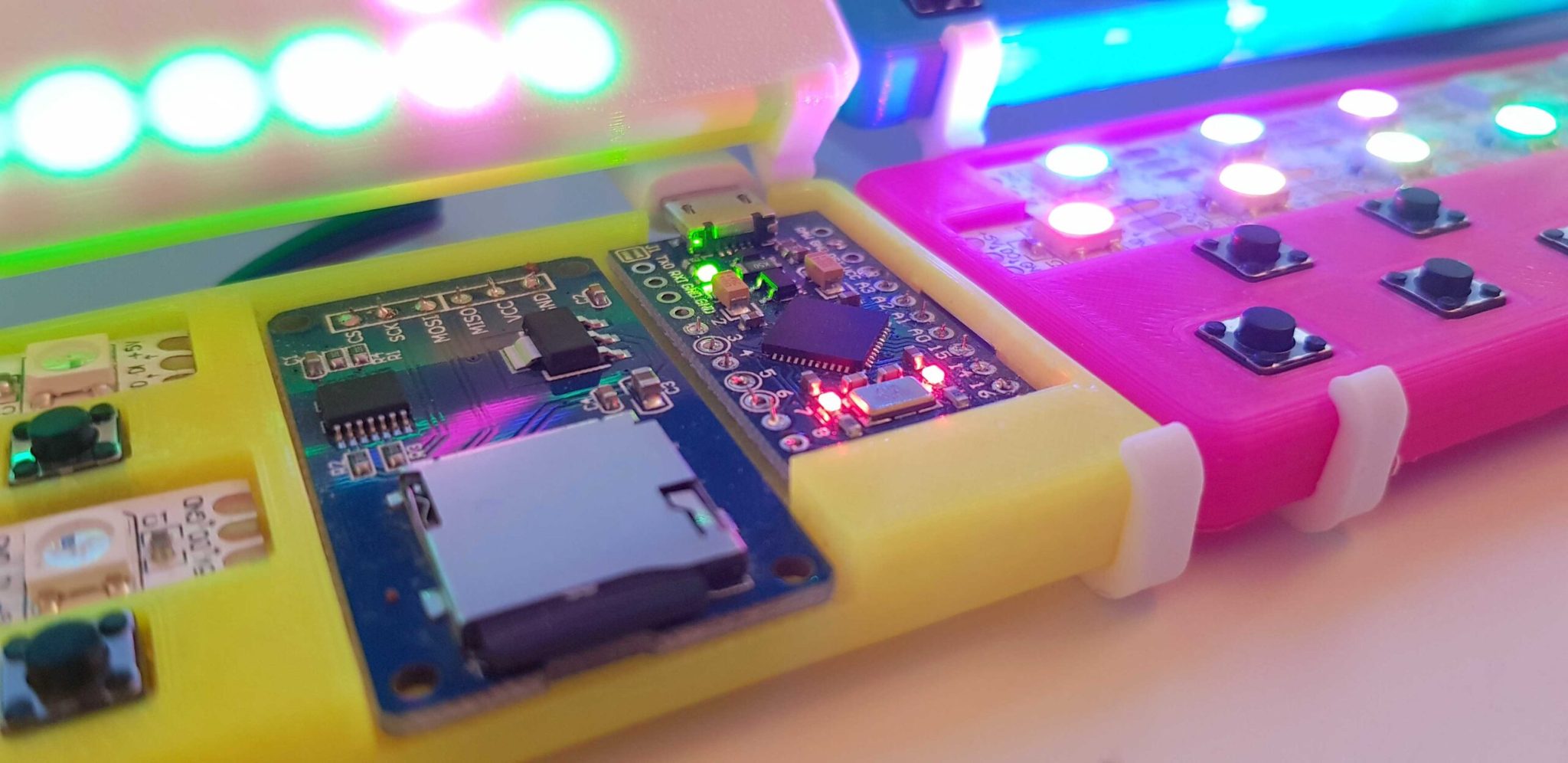

Dubbed the LEET Synthesizer, the fun project can be built for a grand total of $6, and requires only a few basic soldering and embedded electronics programming skills. The device can be used as a keyboard, drum pad, chord keyboard, arpeggiator, or even a step sequencer (or all of the above). Each key also has its own RGB LEDs, allowing for playback visualization. While this does undoubtedly look cool, it’s also extremely useful for music training and editing purposes.

Owing to the fact that MIDI connections were used, the unit can be used as both an input and an output device. As such, it can be connected to any computer with a DAW (Digital Audio Workstation) such as Garageband or Ableton. It’s compatible with Windows, Mac, Linux, and even Android and iOS devices, making it a great portable music development tool.

Building the LEET Synth

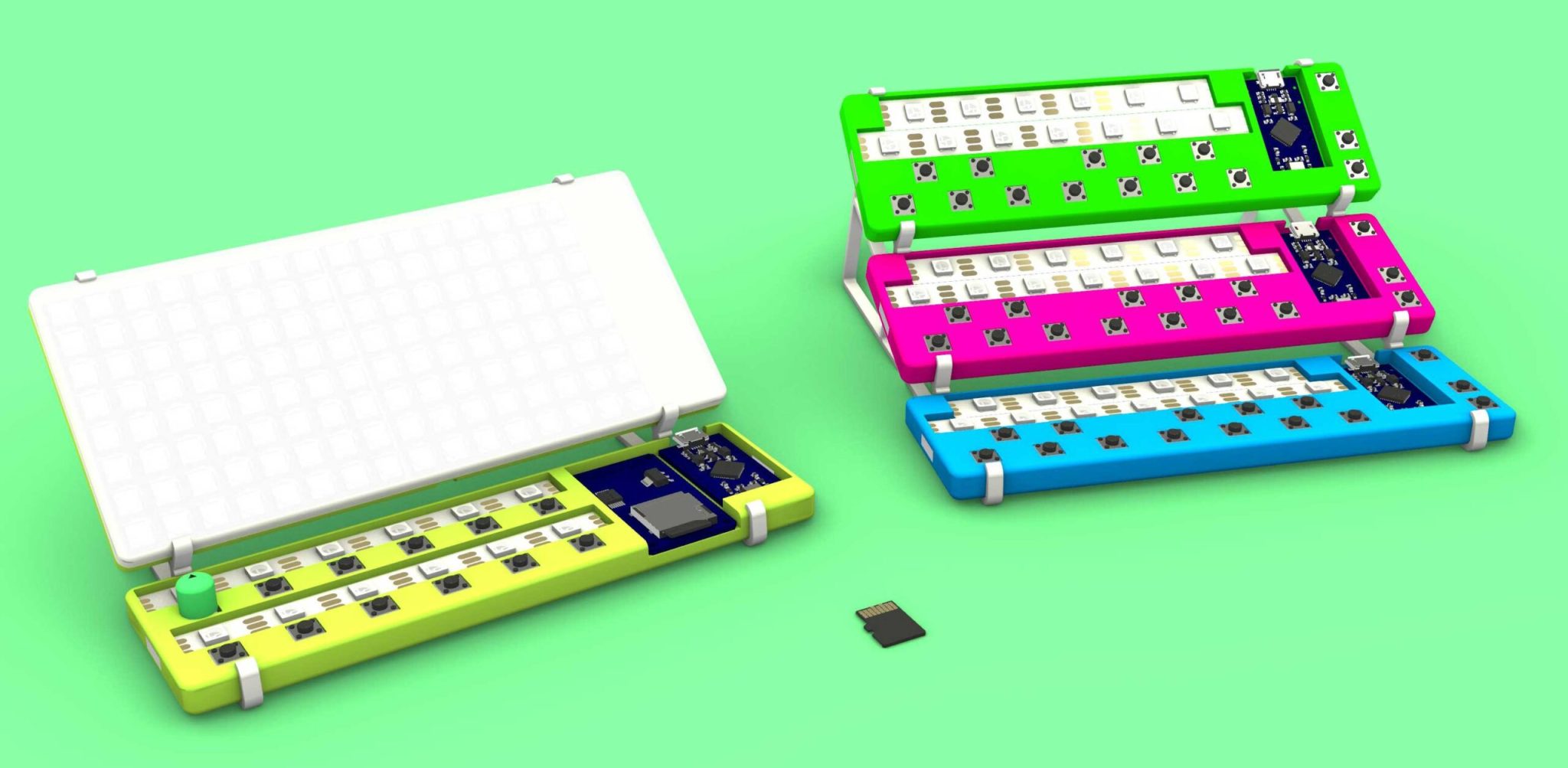

Von Konow states that the LEET should be easily buildable by anyone with a 3D printer and a dream. By design, the 154 x 45 x 8mm device uses few components, and they’re all accessible and affordable.

The Bill of Materials is as follows: an Arduino pro micro, 13 LEDs, 15 6×6 tact switches, and 34g of PLA filament (and an FDM printer and soldering station). While the consumables can be purchased on eBay for a total of around $6, users interested in building the more complex sequencer unit will also need a micro SD reader and 2x additional 8×8 LED matrices.

Whatever the chosen unit, the device is built around a central 3D printed circuit board (PCB) core, which serves as the exterior of the synth and houses all of its individual components. Much like any circuit board, the core features a set of integrated wire channels that can be used to connect all of the components internally. The core can be easily replicated, is inexpensive, and means you won’t have to wait for a PCB to be delivered. It can be printed in under 4 hours, and should take no more than an additional 2 hours for all of the soldering.

Von Konow adds: “I designed the devices to be simplistic, solid and playful. The design might be called retrofuturism since they are inspired by old-school mainframe computers from the 70s with lots of blinking lights like PDP-10, but the addition of full color LEDs and 3DPCBs makes them futuristic at the same time.”

Make it your own

To truly replicate the feeling of a low-budget 80s hacker movie, Von Konow encourages tinkering with the LEET to put your own spin on it. The Arduino framework is easy to tweak, and can be used to integrate new functions depending on an individual’s needs. Wooden stands, light sensors, and additional speakers can all be implemented for a highly-customizable product.

Von Konow concludes: “I kept the form factor for each unit similar and designed a simple snap-on stand where two or three units can be stacked and tilted for easy access. The units can also be equipped with magnets, allowing them to be snapped together side by side. With this approach, a two or three octave keyboard can be constructed by joining modules next to each other.”

Both the 3D printing and open-source communities have been known to mesh quite well in the past, and are often one and the same. Researchers from Intel Labs recently developed an open-source 3D printed smart robot that can be built for less than $50. When combined with a modern smartphone, the PLA Openbot is able to navigate autonomously, and its real-time sensing capabilities enable it to conduct recon tasks such as following people.

Elsewhere, at MTU, Dr. Joshua Pearce recently released the design plans for a low-cost, high-temperature open-source FDM printer. Dubbed the ‘Cerberus’, the three-headed machine can be built for less than $1000 and is capable of printing a number of high-performance materials such as PEKK and Ultem/PEI.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D printed LEET Synth. Photo via Johan Von Konow.