In a bid to give back to the open-source community, 3D printer manufacturer CEL-UK has released its AutoMaker software under an open-source license.

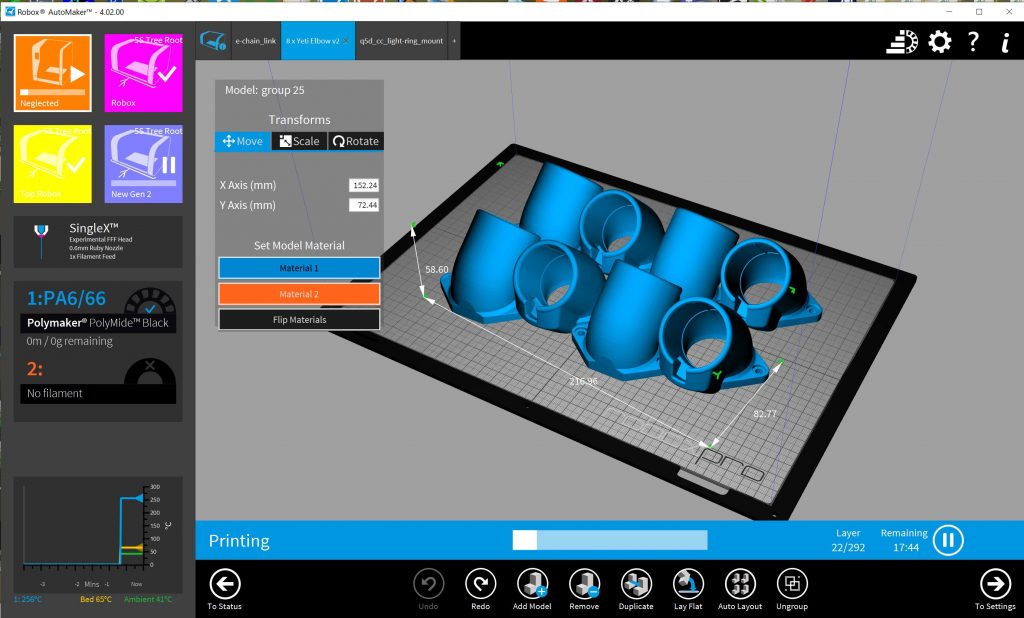

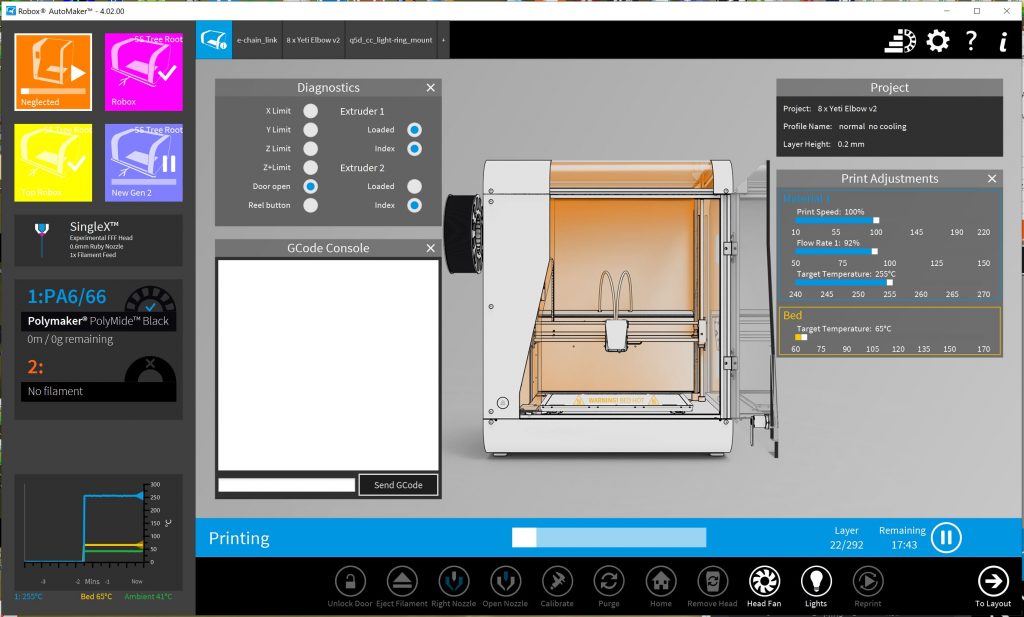

The code is the driving force behind the company’s Robox FDM 3D printers, and provides users with slicing, control, and error checking functionality. With the source code now available to the public, users in the maker community will be able to tailor the software to their own specific requirements. This means that tech-savvy individuals will be able to integrate new features and program new hardware actions as and when needed.

Chris Elsworthy, Managing Director at CEL-UK, states, “We are so incredibly proud and excited to open our work and offer all our great customers the ability to help us and each other continue the development of what we feel is one of the greatest workflows on an FDM platform.”

A return to roots

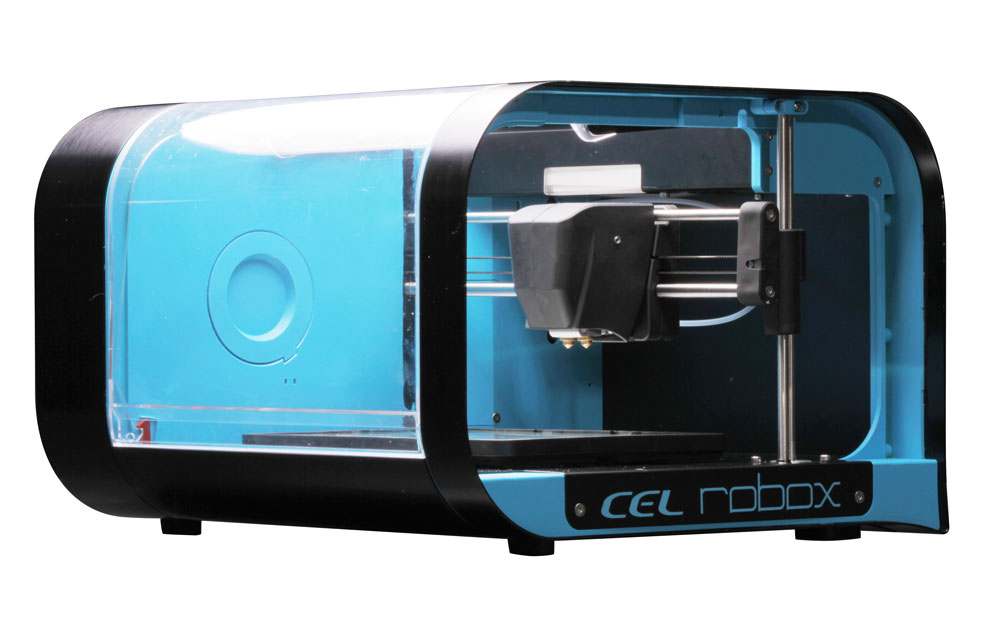

Seven years ago, when consumer 3D printing was really only just taking off, CEL-UK launched its Robox 3D printer via a Kickstarter campaign. The system came fully built and ready-to-use, which wasn’t as common as it is today. Like many others, the company leveraged the collective knowledge of the open-source community to speed up the development of its product, but quickly outgrew the technology and went on to develop its own electronics, hardware, and software, including AutoMaker.

While many of CEL’s competitors at the time were closing the source on their technology for commercial reasons, the company wanted to build a more accessible ecosystem and reach a wider audience. The route it went down was one of semi-open-source, whereby customers were encouraged to tinker with the process but many of the inner workings of the technology were still hidden away. This approach enabled CEL to gain traction with businesses and schools but still limited the maker and open-source communities who sought after full access.

Elsworthy adds, “It has always been our intention to open up all our work for our customers to use, to allow the development of the platform to continue and ensure the community that we have worked so hard to gain continues with their investment into our project. It seems like a perfect time to open-source all our software so that our customers and anyone else that has followed our progress can scratch some of their own itches.”

A new chapter for CEL-UK

The public release of AutoMaker is only one part of the company’s vision for the near future, which includes the ongoing development of the Robox product range. Alongside the release, CEL-UK is also launching its new second-generation mainboard for use with its 3D printers. Fully backwards-compatible with all existing systems, the Robox Mainboard 2 comes complete with new features, improved motor driver chips, and reduced noise levels.

Elsworthy and his modest team have also spun-out a company called Q5D Technology, which they are using to develop their new 5-axis FDM technology. According to the company, the project is ultimately intended to ensure “FDM stays at the forefront of additive manufacturing”.

Though not by choice, 3D printer OEM Stratasys will also be losing a set of proprietary rights later this week. The upcoming expiration of patent US6722872B1 will mean that manufacturers worldwide will be able to utilize the two decade-old design of the company’s heated build chamber. With the device entering the public domain, the high-temperature industrial FDM market is expected to see an influx in competition.

Elsewhere, in the open-source community, RepRap founder Dr. Adrian Bowyer MBE has previously made a blog post outlining his design for a solenoid bed heater that can be integrated with FDM 3D printers. Much like CEL-UK, Bowyer is a champion of open-source collaboration, and often posts proposals for novel devices that can be of use to DIY makers.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the AutoMaker status page. Image via CEL-UK.