Dr. Adrian Bowyer, the founder of RepRap, made a blog post on his website earlier this week detailing the design of a solenoid bed heater for use with FDM 3D printers. The British engineer wanted to get the idea out to prevent others from patenting it, explaining that he “thought it was so obvious that someone must have thought of it before”. After a fruitless online search, Dr. Bowyer realized he must have been the first to come up with the concept, but is encouraging people to prove him wrong with evidence.

History in the making

You’d have a hard time coming across an FFF 3D printer that doesn’t have a heated bed today. They’re almost essential for print adhesion and prevent the edges of parts from warping due to rapid temperature changes. Bowyer cites Chris Palmer, aka Nophead, as being the first to invent them back in 2010. It’s also quite common for modern 3D printers to have magnets along the lining of their beds, holding a flexible sheet of steel in place on which parts are printed. The steel sheet is often removable and flexed to peel prints off easier. Bowyer accredits this idea to Josef Průša.

The combination of these two ideas is, reportedly, something that hasn’t been done before. Could Bowyer’s design be another advance for FFF printbeds? Let’s have a closer look.

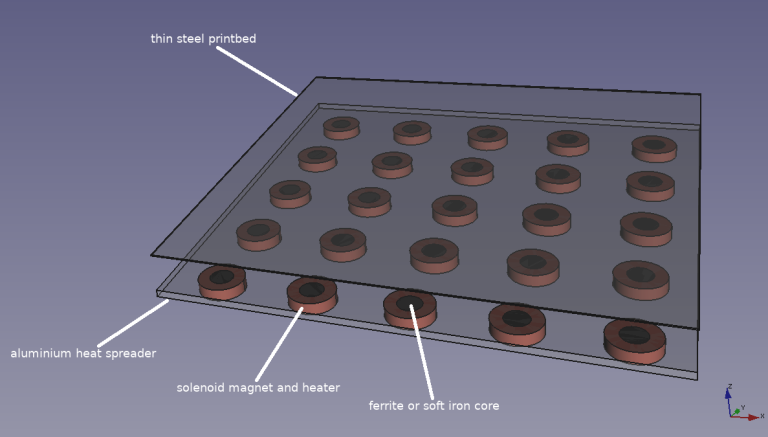

Solenoid bed heater

The design is for a solenoid (a type of coiled electromagnet) attachment that is housed between the heating elements of a printer and the thin steel sheet that the prints sit on. The printer’s controller turning the heating elements on or off also turns the magnets in the attachment on or off. So, when a print is finished and the heating elements are automatically turned off, the magnets go with it and the thin steel sheet at the top is no longer ‘attached’. Bowyer believes that a simple mechanism could be used to then automatically load a blank sheet at the end of the print job, starting the next print without any need for human input. The result – the continuous automated printing of parts on a production line.

To maintain the desired temperature throughout the print, the solenoids would have to be “driven by pulse-width modulated power smoothed through a low-pass filter, or capacitor”. This way, the magnets would stay on and heat would be supplied until the part was finished. According to Bowyer, this should be a fairly simple electrical calculation to find the correct number of coils and the average current that would need to run through them. A heat spreader made of aluminum would be placed on the heating elements to ensure each solenoid received more-or-less identical energy, regardless of the placement of the elements.

Dr. Bowyer’s blog contains all manner of interesting proposals including details of an Electric 3D Printing method would be to print volumetrically.

Elsewhere, in the open-source community, a blog post by software engineer Kenneth Jiang was released detailing the development of an AI software that automatically pauses failed prints.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows solenoid bed heater. Image via Adrian Bowyer.