Dr. Adrian Bowyer, inventor of RepRap, Member of the Order of the British Empire, and the first recipient of our Oustanding Contribution to 3D Printing has proposed a new method of high-speed 3D printing.

Detailed in a blog post on RepRap Ltd., his method combines three different ideas to create a machine with no moving parts, capable of (potentially) creating solid polymer or metal objects within a few seconds.

By sharing his idea publicly, Dr. Bowyer has established prior art for the Electric 3D Printing method. As with RepRap, this means the method is open source and, as such, cannot be patented.

Speaking with Dr. Bowyer, I learn more about the challenges of bringing Electric 3D Printing to fruition, and his intentions for development.

The basics of Electric 3D Printing

Electric 3D Printing is a method that combines three different ideas:

– UC Berkeley’s volumetric 3D printing developed in collaboration with Lawrence Livermore National Laboratory (LLNL)

– An electric 3D scanning technique from open source biomedical imaging company Mindseye Biomedical, and,

– The electropolymerization method of building polymeric films

A type of reverse CT scanning, in UC Berkeley’s method, object .stls are converted to Radon transform data and projected into a volume of light-reactive resin. By rapidly rotating the resin, the projections solidify the material, 3D printing objects in seconds. Put simply, Dr. Bowyer’s method seeks to do the same as this, only using electric currents instead of projections.

With Mindseye Biomedical’s Spectra imaging system, Dr. Bowyer provides evidence that it is feasible to create 3D data using electricity. Developed as a more affordable, accessible alternative to CAT scanning, instead of X-rays, the spectra uses conductivity data from electric currents to build a 3D map of tissue and other objects.

With electropolymerization, the method has the final piece in the puzzle, proving the ability to polymerize a liquid polymer into a solid using electricity.

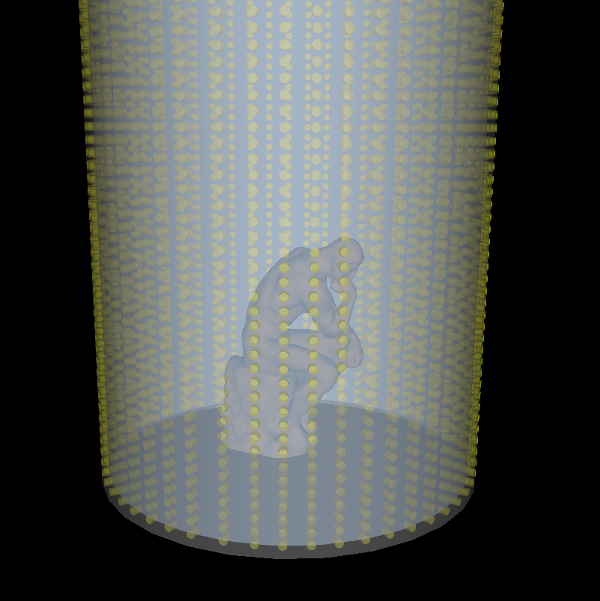

At its present stage, as a concept, Dr. Bowyer has drawn a basic diagram of how the Electric 3D Printer would look. A cylindrical bath would be made to contain a fine array of electrodes in a square grid. In a reverse of the Spectra system, electric currents, representative of 3D data, would be emitted through a liquid monomer, solidifying it into the desired object.

What are the benefits of Electric 3D Printing?

As the aim of Electric 3D Printing would be to print volumetrically the method comes in direct competition with light-based methods, like the one at UC Berkley/LLNL, that are already working on how to make the technology feasible. There are other potential downsides too, namely that electric moves in a much more complicated pattern through a conductor than light does, meaning it would make computation much more challenging.

However the upsides, if the technique works and the Poisson’s equation of the current is solved, are that the patterns you can make using an electrode array would be much more complex than those achieved by an array of straight light. Dr. Bowyer explains, “This means that you should have more subtle and versatile control than with a light-based system.”

Putting ideas into practice

Still a speculative idea, Electric 3D Printing would, of course, have its challenges, not least in identifying the correct electrical intensity to build objects, but also on monomer composition. Regarding the latter, Dr. Bowyer told me “One needs a conducting monomer, of course, and, in fact, I think that getting the chemistry right would be the biggest challenge.” Although, he adds, “that may be because I am not a chemist…” It is also unclear what properties electrical curing might have on a finished part, “Like a lot of conventional SLA I would expect post curing would be needed, at least initially,” Dr. Bowyer explains, “It would be extraordinarily good luck if the process, on being made to work at all, produced a mechanically and chemically optimal part.”

“The other big problem that I see is one of modelling and computation: as the material solidifies I would expect its electrical conductivity to change, and this would have to be allowed for in the programming of the electrical currents through the reaction bath.”

For further development, Dr. Bowyer said he would like to work on the system himself, and is open to collaboration with others. As a proof of concept experiment, Dr. Bowyer suggests using a hydrophilic monomer in water, as it is easy to make water conduct, and it is an excellent solvent. “This means that the number of different substances that could be tried to use in the polymerization reaction would be large,” Dr. Bowyer adds.

In addition, moving to inorganic chemistry, Dr. Bowyer proposes replacing the monomer bath with an electrolyte like copper acetate or sulphate. In theory, this would make it possible to create metal objects using the same high-speed method, though, Dr. Bowyer speculates, it might be more challenging.

For more ideas in development subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Visit 3D Printing Jobs for new opportunities in this field.

Featured image shows a demonstrative image of the Electric 3D Printing system proposed by Dr. Adrian Bowyer. Image via RepRap Ltd.