Researchers from Intel Labs have developed an open-source 3D printed smart robot that it is possible to build for less than $50.

Once combined with a modern smartphone, the additive bot is able to navigate autonomously, and its real-time sensing capabilities enable it to conduct recon tasks such as following people. The PLA-based Openbot has also been designed to be easy to build too, and its STL files have been made freely available online. By making their design public, the researchers hope that creators will tinker with and improve their robot to continue developing new applications for it in the future.

“Current robots are either expensive or make significant compromises on sensory richness, computational power, and communication capabilities,” stated the researchers in their paper. “We propose to leverage smartphones to equip robots with extensive sensor suites and access to a thriving software ecosystem, in a small electric vehicle that costs $50.”

The herculean cost of additive smart robotics

The industrial applications of smart robots have created a potentially lucrative market for businesses such as Franka Emika and Clearpath. The advanced tech firms produce highly-sophisticated legged-robots and bionic arms, but these are often well out of reach for academic institutions, costing north of $10,000 each.

Previously developed low-cost four-wheeled alternatives can broadly be sorted into three classes: tiny robots, swarm robotics and larger vehicles based on RC trucks. Swarm bots are more economical to make, but they often feature very limited sensing capabilities. By contrast, larger custom-made creations have more abundant sensors, but it has proved difficult to develop autonomous navigation for them.

“Robots are expensive. Legged robots and industrial manipulators cost as much as luxury cars, and the cheapest robots from Franka Emika or Clearpath cost at least $10K.”

Many modern smartphones come equipped with mobile AI processors, and their ability to run complex AI models in real-time has led researchers to experiment with a smart robotic cross-over. Similar projects to that of the Intel team have previously been launched on Kickstarter, with the Botiful telepresence device and the Romo smartphone-powered drone finding success on the platform.

The Wheelphone design, which was popularized on the open-source software site Github a few years ago, probably represents the most similar layout to that developed by the Intel researchers. Unfortunately the technical limitations of the Wheelphone limited its top speed, and its high cost of around $250 caused it to be shelved, with the last update released around two years ago.

The Intel duo’s 3D printed Openbot

Inspired by projects such as Google’s Cardboard VR device, the researchers hypothesized that a smartphone could play a similar role in robotics. Using off-the-shelf parts to create a cheap physical enclosure, while allowing the mobile to act as its ‘brain,’ has plenty of benefits. In addition to being more cost-effective, the vibrant ecosystem of existing mobile apps offer the potential for numerous applications to be developed using the same hardware.

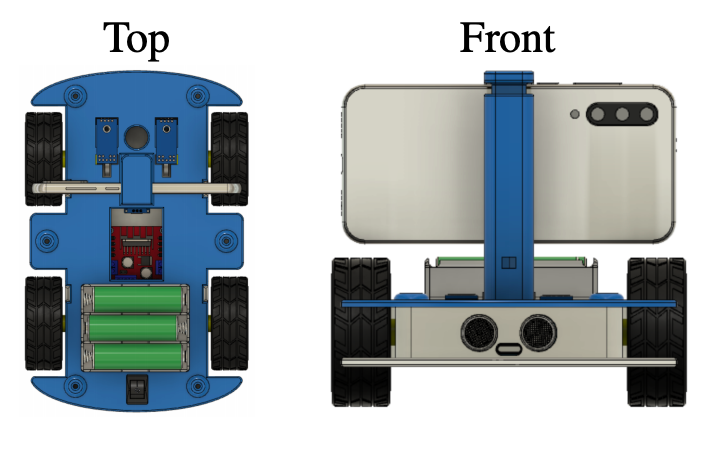

Using only an Ultimaker S5 system, the team produced the chassis, consisting of a bottom plate which is fastened to a top cover with six screws. The top plate itself features a universal smartphone mount with an adjustable spring to make it compatible with different phones, and an opening for attaching a USB-powered Arduino microcontroller.

The Openbot was programmed using a two-piece custom-designed software stack. In order to provide an interface for the operator to collect datasets and control the bot’s workload, the Intel team developed an android-based app. This was supplemented by an Arduino nano microcontroller, which controls low-level functions, and acts as a bridge between the vehicle body and the smartphone.

Taking a total of 23 hours to build, the smart robot proved capable of speeds of up to 150cm per second, making it markedly quicker than its predecessors. Aiming to assess the sensing capabilities of their Openbot, the researchers tested to see if it could follow someone independently, or even achieve autonomous navigation. Using mid-range smartphones, testing showed that the bot was able to track people at speeds of 10 fps or higher.

Although performance did prove to be device-dependent, even the cheapest phones were able to follow people for around 50 percent of the time. The researchers also trained a “driving policy” for use on smartphones, which was capable of navigating corridors and turning at intersections. Overall, the bot proved consistently able to deal with previously unseen environments, including novel objects, and dynamic obstacles such as people.

Concluding their tests to be a success, the Intel duo expressed optimism that their creation would make robotics more scalable and accessible than was previously thought possible.

“We have developed a combination of hardware and software that turns smartphones into robots,” they concluded in their paper. “We hope our work will open new opportunities for education and large-scale learning via thousands of low-cost robots deployed around the world.”

For those interested in building the Intel research team’s Openbot themselves, the files can be accessed via Github here.

Previous 3D printed smart robots

A number of other research groups have leveraged 3D printing to fabricate smart robotics, and these additive creations have taken on a vast array of shapes, sizes and functions in recent years.

In July 2020, engineering company Scheurer Swiss GmbH partnered with a group of ETH Zürich students to develop their “Rowesys” 3D printed automated robotic weeding system. The compact weed killing bot is designed to be a sustainable alternative to using herbicides in agricultural farming.

Researchers from The NYU Tandon School of Engineering and the Max Planck Institute for Intelligent Systems (MPI-IS) have built an open-source 3D printed robotic dog. The ‘Solo 8’ is designed to be low-cost and scalable, allowing those with a limited budget to construct and build an additive pet of their own.

Robotics engineers at the Georgia Institute of Technology have used 3D printed parts to create an energy-efficient ‘Slothbot.’ The robotic mammal is currently being used at the Atlanta Botanical Garden to closely monitor the animals, plants, and environment there.

The researchers’ findings are detailed in their paper titled “OpenBot: Turning Smartphones into Robots,” which was co-authored by Matthias Muller and Vladlen Koltun.

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a diagram of the Intel team’s 3D printed Openbot. Image via Intel.