Luxury aircraft parts manufacturer JBRND has begun using 3D printing and rapid prototyping to reduce the lead-time needed to develop new products and components. Most recently 3D printed parts were used to test fit parts on a GE turboprop engine for high-end jet manufacturer Nextant Aerospace.

Jeff Bonner Research & Development manufactures aerospace parts & assemblies for the commercial, military, and luxury markets, all from their 65,000 sq.ft workshop in San Antonio, Texas. After a boom in demand for high-end components for their Luxury division they split off JBRND into a new stand alone company that will cater directly to their VIP and VVIP clients. In order to serve those demanding clients they have started using 3D printed prototypes and assembly guides to speed up the development of new parts and components.

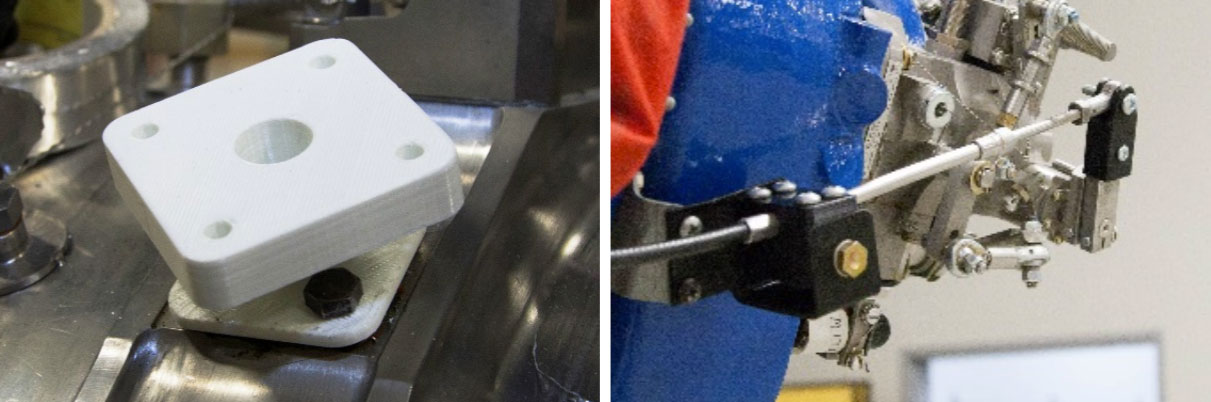

Recently they drastically reduced development time by 3D printing prototyped parts in order to check fit them while adapting a H75 turboprop engine. The modified GE Aviation engine is being created for the latest model of the luxury G90XT jet from Nextant Aerospace and will feature the first ever Electronic Engine Control (EEC). The EEC interfaces directly with the planes avionics systems and will give the high tech engine complete auto-start capability

This rapid prototyping allows newly developed components to be test installed, articulated and checked for clearance and movement tolerances. The final models can then be used to create the drawings and manufacturing guides that define construction materials, inspection requirements and post processing features. This portion of the process is so fast that the final part is just being completed by the time the approved drawing is released.

This is a highly effective method for creating new parts without the need for wasting extremely valuable time on the workshops CNC machines. This way any kinks and design flaws get worked out before anything is milled or tooled, allowing for the CNC machines to be used for more important projects and not wasted on prototyping. Not only reducing final production time, but drastically reducing development costs.