The Pantone Matching System (PMS) from New Jersey-based color measurement specialist Pantone is the most widely used color standard in the world. Through the development of full-color 3D printers, it make sense then that this technology should also conform to the PMS, and attain the ability to replicate color in a way that is recognizable and, ultimately, 100% repeatable. Already, some systems, including the Stratasys J735 and J750, and FiberForce filament are validated by Pantone. But, what’s next for the system? 3D Printing Industry speaks to Iain Pike Director of Partner Business Development at Pantone, to learn more.

A universal language of color

Pantone is a part of the Danaher Corporation which acquired the parent company of Pantone, Xrite, based in Michigan. Xrite is one of the leaders in color measurements and management products and is also the publisher of the AxF file format which is used to capture and store material characteristics in CAD software.

According to Pike, Pantone was founded to solve the problem of communicating color in the design and manufacturing process. And its raison d’etre is “to provide a universal color language that allows people to make color critical decisions at every different stage of product flow.” This language is indicated in the PMS by numbers, and so to express these colors, designers and manufacturers need only communicate at the level numeric codes. “Starting with brands, and moving all the way through to the supply chains of those brands,” Pike adds, “[Pantone] communicat[es] colors so that the design intent can be realized in the final product.”

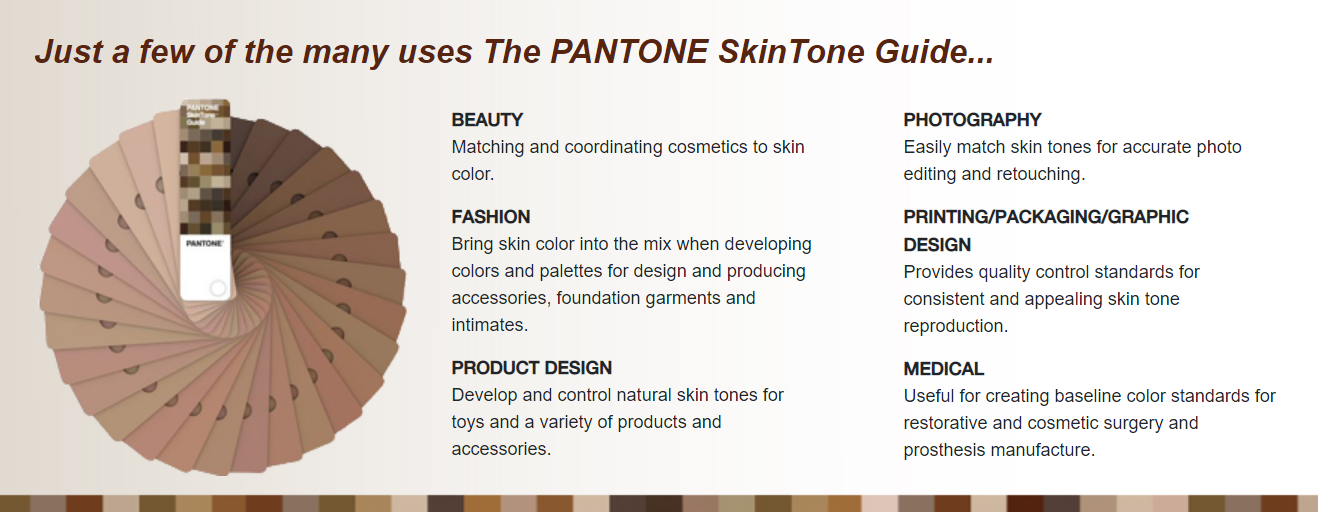

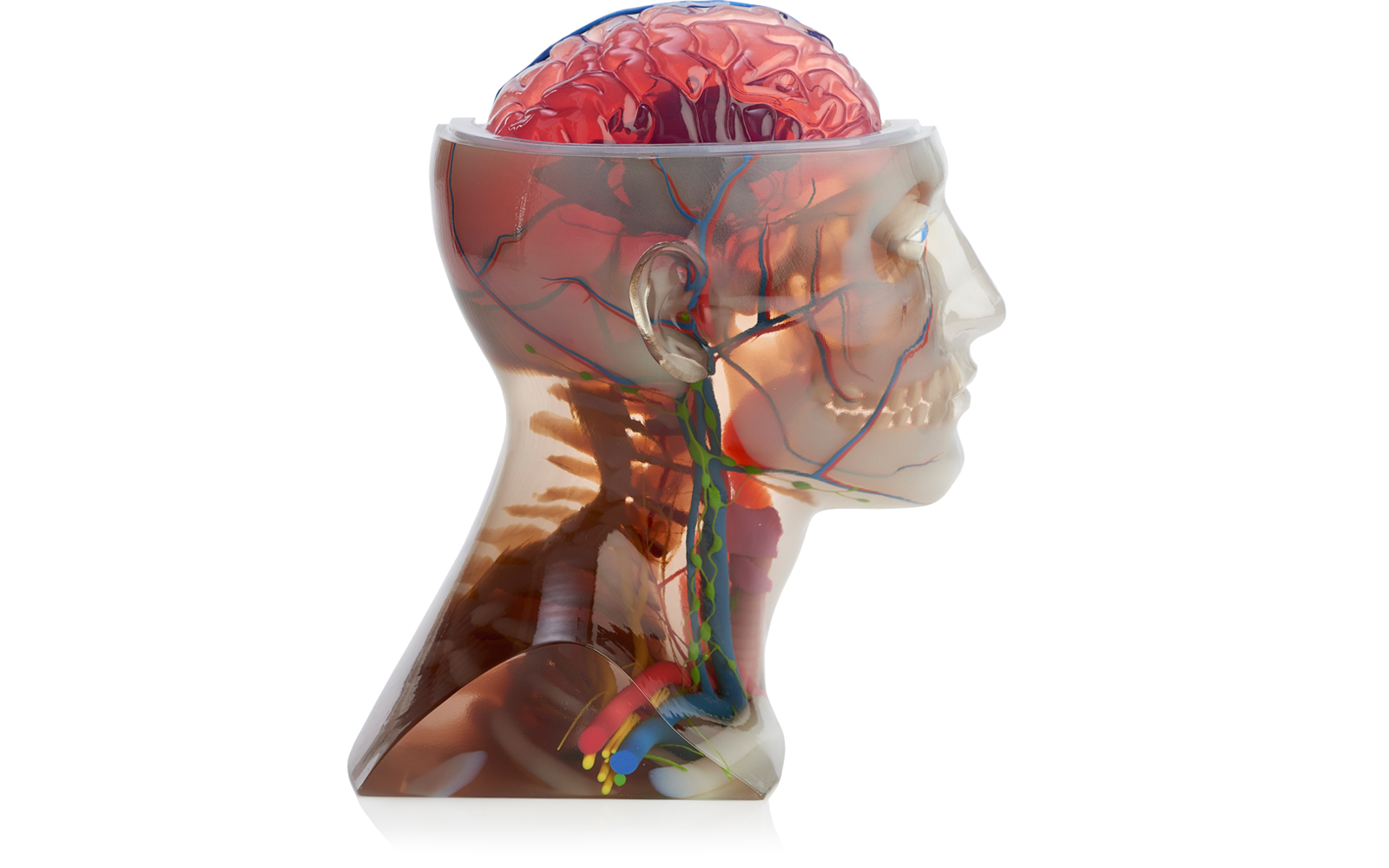

At present, over 10 million designers and manufacturers use the Pantone color scheme and other products, referencing the company’s swatches and references like printed Formula Guides and digital versions. One unique version of this material is the Pantone Skintone Guide which is a “comprehensive visual reference of human skin tones” based on Global research of different skin colors. In this project, Pike continued, “We categorized into 110 unique colors. So these skin tones are used pretty extensively in the cosmetic field or for medical prostheses, etc.”

Pantone and 3D printing

The color validation process developed by Pantone is one way in which 3D printer OEMs can overcome standardization challenges. Machines licensed under Pantone, like the Stratasys J750, are validated by third parties who map colors and find the limitations of the machines. “One of the things that happen in our Pantone Validation Process is that we can assess the ability of a given device […] to simulate the full range of colors in the Pantone publication,” explained Pike. These tests establish limitations of the software and machines to be used with PMS. “Sometimes the colors aren’t achievable, they are out of the Gamut,” Pike adds, and in case of Stratasys the 3D printer manufacturer came up with an accuracy indicator which works like Harvey ball ideograms. “It is either full up, which means it is a good quality representation, or it’s 25, 50, or 75 percent accurate,” Pike explains, referencing pie-chart like Harvey balls. “That’s what gives you an estimate idea about how well that particular color will match the original Pantone materials.”

Speaking generally of PMS’ role within the industry, Pike believes that “The potential for color in 3D printing is big.”

“There is one side of 3D printing that is more functional,” he adds, “and there is a whole other side that requires the aesthetic of color. Not just any color, but accurate color, consistent, pleasing color.”

There is also potential for the PMS to be used in post-processing systems, like DyeMansion’s DeepDye Coloring (DDC) technology, which is currently validated with the competing RAL color matching system. DyeMansion offers 170 RAL colors out of the box and can also develop any Pantone TPG color with its color matching technology.

When it comes to material companies Pike says, “Most of the suppliers of filaments already have a certain color range, and its quite easy for us to work with them to see that if any of those colors align better with any of our Pantone identities.”

“And if they marketed those products also using Pantone identities, they might be able to attract more users for their filaments.”

Each year, Pantone Color Institute publishes the Pantone Fashion Color Trend Report, a survey of popular colors of the year. This year’s top color is ‘Living Coral’ with a Pantone code: 16-1546. Filament makers can take advantage of this by manufacturing filaments in the color of the year category. FiberForce, for example, currently sells ‘Living Coral’ color filament.

To learn more about color 3D printing, subscribe to our 3D printing newsletter. You can also join us on Twitter and Facebook for live updates.

Looking to start a new career? Visit our 3D Printing Jobs board.

Featured image shows the Pantone Formula Guide, printed on a coated paper. Image via Pantone.