General Lattice is a 3D design software startup headquartered in Chicago, Illinois. Currently less than one year old, the company is focused on a niche part of design for additive manufacturing (DfAM). Working to optimize lattice structures, the company is one essential prong in facilitating real-world, end-use applications of 3D printing that deliver on performance as well as aesthetic appeal.

There are three co-founders of General Lattice: Nick Florek, the company’s CEO, Alex Rhoades, COO, and Marek Moffett, CTO. Florek has experience in the steel manufacturing industry, and for two years prior to founding the company led key supply chain initiatives for high capacity forklift manufacturer, Hoist Liftruck Mfg.

Rhoades, on the other hand, is a Supply Chain Management and Corporate Innovation graduate of the Kelley School of Business at Indiana University, working as an operational strategist and decision maker for the company.

And Moffett helped create General Lattice following following work as an application engineer at Fast Radius. In his five year’s experience in DfAM Moffett worked with a variety of technologies, including Carbon DLS, that helped make the SILQ office chair for Michigan headquartered furniture design company Steelcase.

Peter Winslow, General Lattice’s Director of Marketing and PR, completes the team as a graduate of Lawrence University and former Chicago news reporter.

With its tools, currently in development, General Lattice looks to support mass personalization, with “design driven by the consumer.” For this, the company offers a full end-to-end solution, providing design, manufacturing and support services.

3D Printing Industry: When was General Lattice founded? And what was the catalyst for founding the company?

Nick Florek, General Lattice: Founded in February of 2019, General Lattice was started with the goal of making designing for additive a seamless experience. Beginning with an understanding of the advantages of additive manufacturing (part consolidation, mass customization, and lattice generation), General Lattice recognized a void in software that supports these incredible benefits. Having worked with traditional CAD tools and auto-generated lattice packages, General Lattice felt there was a need for a cohesive solution and set out to come up with one.

3D Printing Industry: What does your company do?

Nick Florek: General Lattice is a computational design and digital manufacturing company. With the mission of improving the human condition through next generation design and manufacturing, General Lattice is working to create a comprehensive design platform, created for additive from the ground up.

3D Printing Industry: How does your company fit into the additive manufacturing ecosystem?

Nick Florek: With a slurry of ad-hoc software design solutions available on the market, General Lattice focuses on erasing the pain of using multiple pieces of software by creating an all-in-one design platform that seamlessly takes users from design to manufacturing. Using advanced lattice tool kits, true iso-geometric FEA analysis, and meshless data handling, General Lattice’s design platform unlocks the true potential of what is possible through additive manufacturing.

3D Printing Industry: What are the biggest challenges faced by your customers?

Nick Florek: Today, the largest challenge our customers face, whether they recognize it or not, is access to tools that facilitate true value-add designs with additive technology. General Lattice believes that people are just starting to recognize what is possible through additive and wants to deliver a platform that allows users to create the next generation of products.

3D Printing Industry: What companies/industries does General Lattice serve

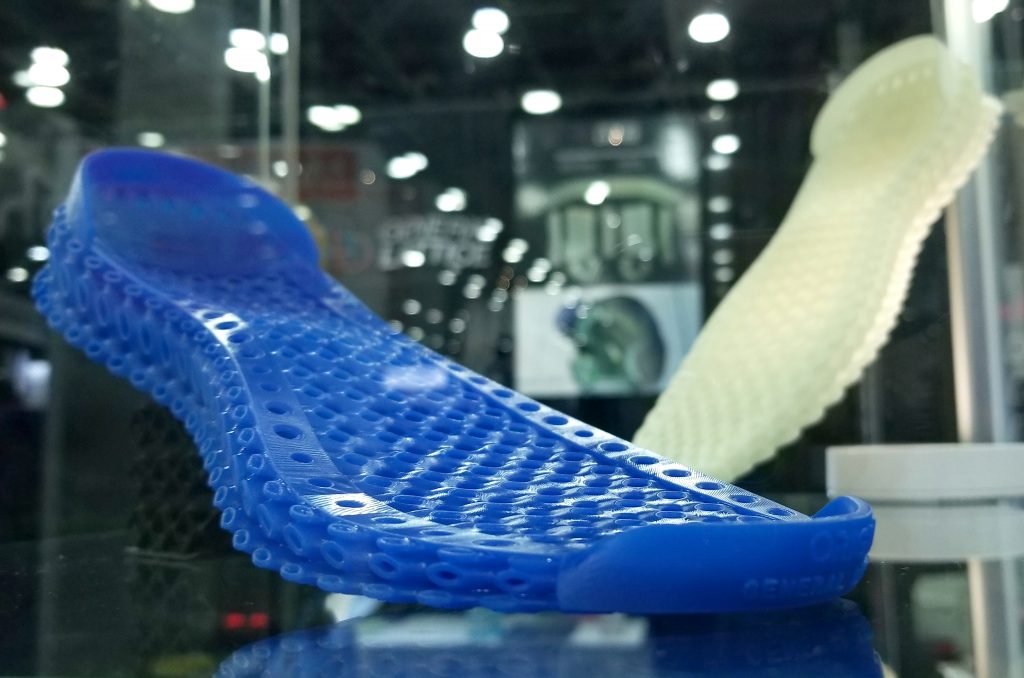

Nick Florek: General Lattice focuses on serving companies interested in integrating or adding additive manufacturing into their product offering. From consumer goods, to medical devices, to construction and architecture, General Lattice feels additive manufacturing has the potential to touch an incredible array of industries. With hardware heavily influencing the current product possibilities, General Lattice has seen most of its customers come from the consumer goods sector with an emphasis on sporting goods.

3D Printing Industry: How would you describe the roadmap for your enterprise over the coming years?

Nick Florek: With its design platform currently under development, General Lattice offers its design expertise on a project-to-project basis working directly with customers. However, General Lattice’s goal is to make its tools available to everyone in the near future.

3D Printing Industry: Is there anything else you would like our readers to know about?

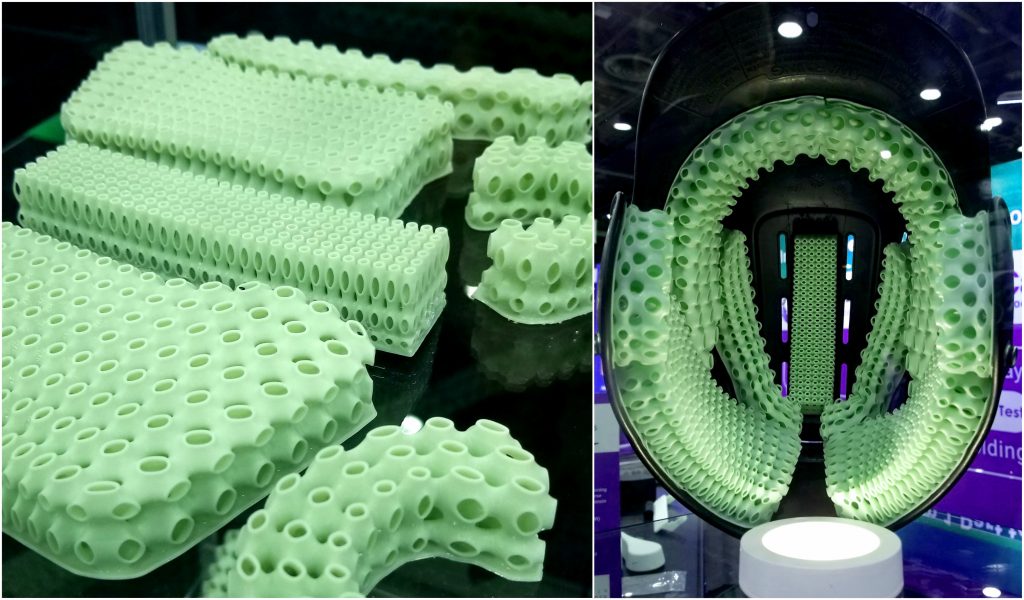

Nick Florek: One key part of General Lattice’s design platform is the integration of its meta-material library. Defining meta-materials as a combination of material, unit cell, and unit cell variables, General Lattice is working to physically test and analyze these meta-materials to more accurately meet physical product requirements.

More information about General Lattice is available here.

Get all the latest 3D printing news direct to your inbox, subscribe to the free 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a change of pace? Seeking new talent for your business? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows a graded 3D printed lattice designed by General Lattice. Photo via General Lattice