Poietis, a French biotechnology company, has announced a partnership with Servier Laboratories, a privately owned global pharmaceutical company, to use 3D bioprinting technologies to create a 4D liver toxicity detection model capable of identifying drug-induced lesions.

“We believe 3D Bioprinters are more than robotic pipettes,” Bruno Brisson, Co-Founder and Vice President of Business Development at Poietis, told 3D Printing Industry.

“So, the 4D Bioprinting paradigm is: guiding or programming self-organization. The goal is then to determine appropriate 3D micro-patterns (blueprints) of tissue components (cells) so that specific tissue function emerges with time considering both internal interactions and interactions with host (external).”

Combating drug-induced liver disease

Drug-induced liver disease occurs as a result of medications, such as vitamins, hormones, herbs, as well as drugs, and environmental pollution. This toxicity in the liver causes lesions, which if not detected, can lead to liver failure and hepatotoxicity – chemical-driven liver damage.

The scientific partners have identified weaknesses in current preclinical detection models which use animal models and cell cultures of human liver cells to predict toxicity. As these models cannot fully replicate the human liver, the results are limited as the hepatotoxic potential is poorly detected.

Liver toxicity testing is significant during preclinical trials with investigational drugs, thus, the scientists have developed a bioprinting method which uses different types of human liver cells and immune cells that imitates the complex multicellular tissue structure of the liver. This model will demonstrate higher accuracy than its predecessors, therefore becoming a vital tool when testing for adverse effects of developing medicinal products.

“We actually introduced the concept of 4D Bioprinting as a new paradigm for engineering complex tissues with our laser-assisted bioprinting technology for more than 3 years,” explained Brisson.

4D printing in medicine

Brisson explains that standard in vitro liver models used in drug analysis is produced with a two-dimensional single layer cell tissue. However, with advancements in 3D printing for regenerative medicine, scientists have been able to create 3D printed cell scaffolds for cell growth.

As the cell structures grow, they can be used to repair parts of the human body, particularly organs, with the body’s original cells. Combined with the concept of 4D printing,3D printed structures with morphing capabilities, the cell structures are able to expand as a result of its changing environment i.e. water and heat. Brisson added:

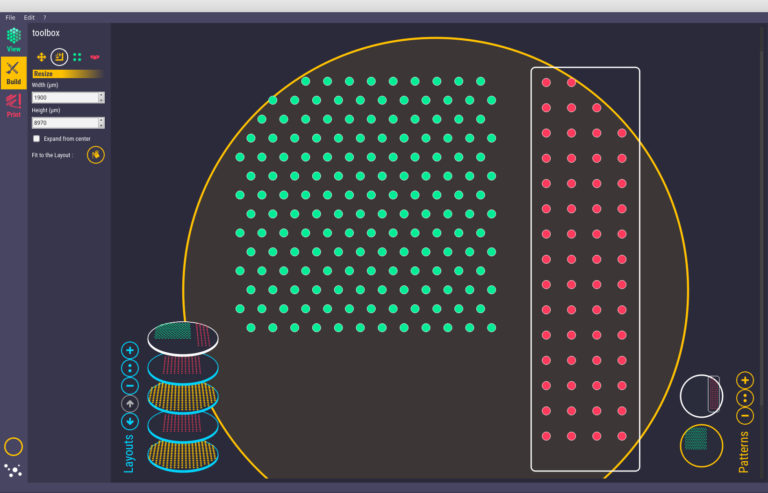

“[Time] is something that needs to be taken into account since the conception of your bioprinting processes for a given specific tissue (and especially with biological and cytocentric CAD software).”

The model will be validated by testing a panel of compounds known to induce, or not induce, liver toxicity. The liver model product is expected to be ready in approximately 18 months.

Keep up with the latest 3D printing news by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Searching for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows Poietis’ Cytocentric CAD tool which can define and locate the position and environment of each cell within three-dimensional tissue structures. Image via Poietis.