Scientists at the University of Pittsburgh Swanson School of Engineering, are proposing the use of 3D printed phantom heads for MRI testing.

The artificial models are designed to take the place of humans in the analysis and calibration of MRI equipment. Data collected from the process can be used to determine, among other things, whether certain implants are suitable for use within the scanner.

The goal is to provide a much more realistic alternative to computational modeling, and improve the safety of MRI testing.

MRI scanning

The MRI scanner used in the Swanson Radiofrequency (RF) Research Facility is a a whole-body 7 Tesla magnetic resonance imager. This, according to Pitt associate professor of bioengineering Tamer Ibrahim, “is one of the strongest clinical human MRI devices in the world.”

However, caveats to the system includes a potentially-damaging rise in heat omitted by the scanner, and a lack of clarity to the images. Ibrahim explains, “As you move from lower to higher fields, the images produced become less uniform and localized heating becomes more prevalent. We wanted to develop an anthropomorphic phantom head to help us better understand these issues by providing a safer way to test the imaging.”

Making of the phantom

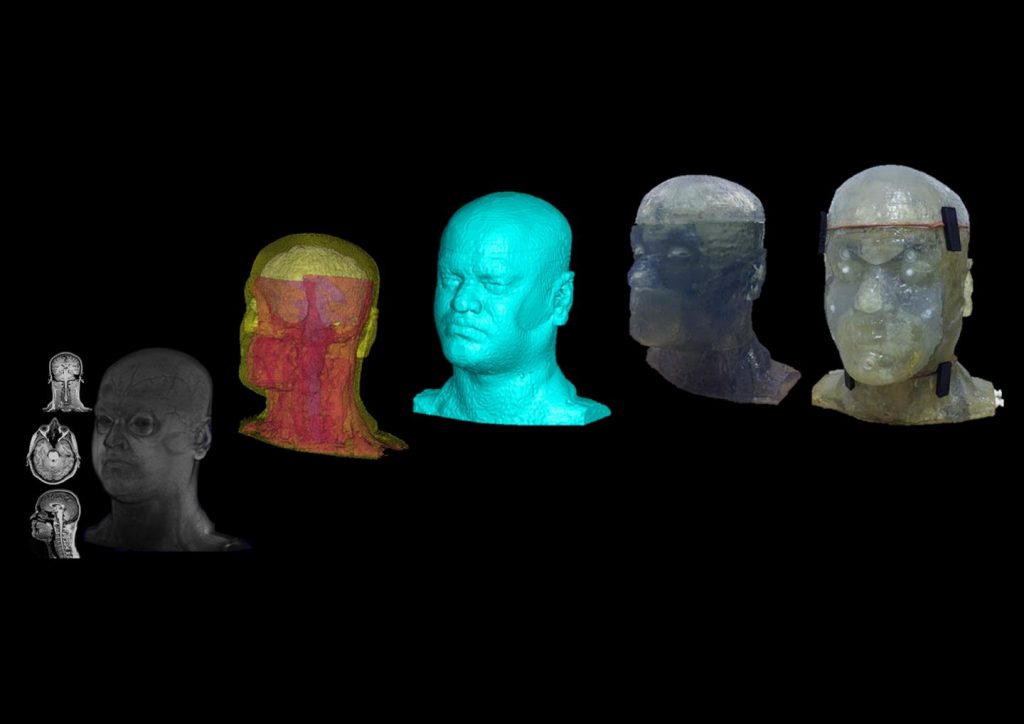

To make the model, the RF Research team 3D scanned the head of a volunteer candidate. This was then classified through a segmentation of all the head’s respective parts, i.e. brain, arteries, neck ligaments etc. Through segmentation, the team identified parts to be 3D printed (the face/skull) and tissue that would be added afterward to fill the head and mimic the electromagnetic response of living matter.

After CAD modeling, a partly hollow shell of the head/skull was 3D printed from DSM Somos resin on a Stratasys system. In the final step, the artificial skull was filled with fluid through specially designed and reusable ports.

The full process is detailed in the paper “Design and fabrication of a realistic anthropomorphic heterogeneous head phantom for MR purposes” published open access in PLOS One. Sossena Wood, Narayanan Krishnamurthy, Tales Santini, Shailesh Raval, Nadim Farhat, John Andy Holmes and Tamer S. Ibrahim are credited as authors.

3D printed head vs. human

It took the team a few months of planning to achieve the most accurate assembly of the head. This was then tested in comparison with the a human volunteer in the lab’s MRI.

Result show that “While our anthropomorphic heterogeneous head phantom does not offer full accuracy in its comparison of the electromagnetic fields to the in-vivo volunteer, it is considerably more comparable than the spherical, anthropomorphic homogenous head phantom or other fabricated heterogeneous phantom studies ”

Though further research is needed to fully develop the phantom’s MRI potential, it is still currently suitable for use in electromagnetic (ER) applications.

What’s next for medical imaging?

3D printing is inspiring many new industry innovations relating to 3D data in medicine. Though it is relatively routine to produce a patient-specific model based on CT and MRI scan data, a more seamless and intuitive approach is required to prepare and handle the data.

In partnership with Siemens Healthineers, award winning 3D software company Materialise is offering Mimics inPrint software that is compatible with medical-standard DICOM data.

A patented technique from MIT’s Mediated Matter Lab and the Wyss Institute for Biologically Inspired Engineering at Harvard University processes medical images on a pixel-by-pixel basis.

Furthermore, researchers at the University of St Andrews in Scotland, are proposing a less-invasive method of medical scanning.

To be the first with all the latest medical 3D printing news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Find your next opportunity at 3D printing jobs or post a vacancy to attract new talent.

Featured image shows the phantom head “From a 3T MRI dataset and a 3D digital segmented image to a 3D printed prototype.” Image and caption via RF Research Facility